Label Sleeving Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Label Sleeving Machine for Packaging Industry

1. Product Description:

Sleeve labeling machine applies to food & beverage industries as fruit juice, tea, drink, dairy product spure water consiments,beer and sports drink etc. This bottle labeling machine is suitable for various kinds of bottle types:round bottlle,square bottle,flat bottle etc. Sleeve labeling machine for round bottle not only has a highly precise position for casting label,but also withstand the perfect shape of the bottle after shrinkage.

2. Product Features:

Adjustable cutter head:unquely cyclotron cut-off,double sided cutting edge with a long service life.

Single postioning center guide pillar:a more stable for label delivery. Synchronous bottle divider:a more stable transmission for bottle.

Bottom set of label brush:a more precision for casting label.

3. Product Parameters:

Model | TB-S150 sleeve label shrinking machine |

Capacity | 150bottles/min |

Main Material | SUS304 |

Diameter of Bottle | 28-150mm |

Height of Bottle | 30-280mm |

Lable Material | PVC,PET,OPS |

Applicable Label Thickness | 0.027-0.13mm |

Applicable Label Length | 30-250mm |

Transparent Label Length | ≥5mm |

Applicable Internal Diameter of Tube | 5-10 adjust free |

Voltage | 380V,50/60HZ,3PH |

Power | 1.5KW-2KW |

Machine Dimension | 2100mm*850mm*2000mm |

Weight | 800KG |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

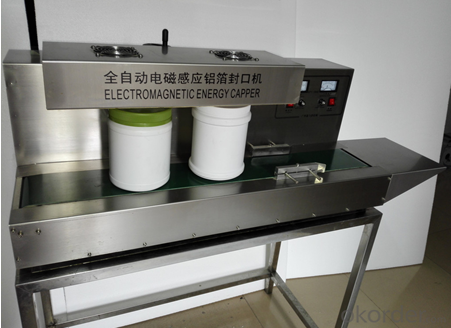

5. Product Pictures:

- Q:What are the components of mechanical equipment (automatic equipment), steel or iron or anything else?

- The machine parts are basically made of steel, and the frame is usually made of cast iron. In theory, parts can be machined and cut, but now they should be finished after forging, which is better than cutting.Parts can not be processed as finished products, and the most important is the final heat treatment program. It includes heat treatment and surface heat treatment of the whole part.

- Q:What should we pay attention to when choosing the quantitative packing machine parts?

- You look for it. If not, try another one. If you don't understand, you can chase me. I'll explain it to you slowly.

- Q:A workshop to machine parts, 5 boxed 80, according to this calculation, there are 340 parts, 20 boxes can be fully loaded?

- 80 / 5=16 (a);340 / 16=21.25 (box) = 22 (box), 20 (box);Answer: 20 boxes can not be fully loaded

- Q:How is the vacuum packing machine assembled? How many parts?

- Vacuum chamber, etc.. Qingdao AI Xun vacuum packaging machine using high quality parts and components

- Q:Single vacuum packaging machine accessories, vacuum schedule, where to sell?

- Packaging machinery specializing in the production of vacuum packaging machine, packaging machine parts, various models complete

- Q:What's the price difference between feed packer and organic fertilizer packing machine?

- Organic fertilizer packaging machine and feed packaging machine is still the main difference between, in the mechanical structure, equipment selection, components and so on

- Q:As a mechanical component inspector, how do you improve the quality of your product?

- In strict accordance with the requirements of the drawings to test, it is best to understand the parts, so that you know what size should be the key control parts are in accordance with its products in the role of design drawing effect on product play, as long as according to the requirements of the drawings focus intention to examine the quality of the products will be enhanced.

- Q:Air conditioning installed in the outer machine packaging, found a small part, please master to help see what is this?

- But the general maintenance plant is not balanced, and must be professional fan leaf manufacturers only, it may be difficult to improve, can only be purchased again fan leaf to replaceThe manufacturer of the shipment will have to make a warranty on this point. It may be difficult

- Q:Can the nylon vacuum packing bag be high and low temperature with mechanical parts?

- Nylon vacuum packing bag has high temperature resistance of 90 degrees Celsius, low temperature, freezing, quality preservation, freshness preservation and odor preservation.And applies to hardware machinery parts.

- Q:How to package machined parts?

- What questions do you ask? How to pack the machine parts, isn't it? If that is the case, I can tell you, basically the packaging machine large cast iron parts are lathe, milling machine, planer, do it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Label Sleeving Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords