Kwikstage Scaffolding System for Building Construction Project CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Kwikstage Scaffolding System for Building Construction Project

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Brand Name:

Surface:

Material.:

Thickness:

Descriptions of Kwikstage Scaffolding System for Building Construction Project

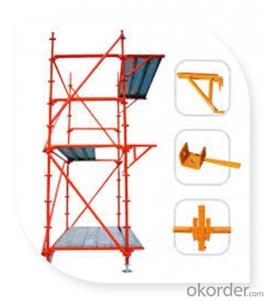

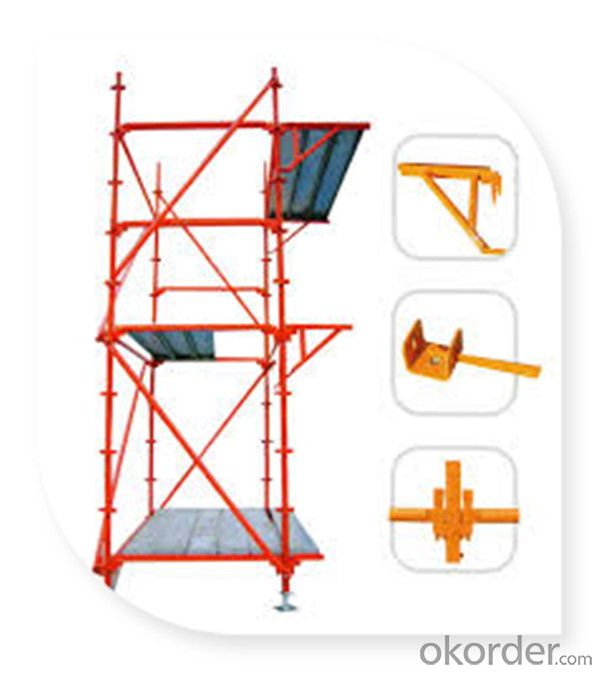

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Kwikstage Scaffolding System for Building Construction Project

Kwikstage Products: Standard; Ledgers; Transom; Steel Plank; Hop Ups; Diagonal Braces; Tie Bars; Toe board Brackets; End Toe Board Brackets; Double C Clip; External Cup Standard

Props and Formwork: Formwork Prop; Formwork Jacks ; Shoring Jacks

Other Accessories: Ladder Beams; Aluminium Stair ; Base Jack; Swivel Jack ; Steel Pallet; Steel Mesh Pallet.A)Kwikstage Standard

Length: 3.0m;2.5m;2.0m;1.5m;1.0m;0.5m Thickness: 4mm Surface: Painted or Hot Dipped Galvanized Certificate: AS / NZS 1576.3-1995 B) Kwikstage Ledgers

Surface painted or hot dipped galvanized Thickness 3.2mm; 3mm Length 2.4m; 1.8m; 1.2m; 0.7m Certificate AS / NZS 1576.3-1995 C) Kwikstage Transom

Surface painted or hot dipped galvanized Thickness 5mm Length 2.4m;1.8m;1.2m;1.0m;0.7m D)Kwikstage Scaffolding Steel Board / Steel Plank

Length 2.4m ; 1.8m; 1.2m; 0.7m Thickness 1.8mm galv.iron sheet Certificate AS 1577-1993 FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Cantilever scaffold technical disclosure Find satisfaction free speed!!!

- 1, steel pipe:(1) the steel pipe shall have the product quality certificate and inspection report with the outer diameter of 48mm and the thickness of 3.5mm of the steel pipe welded to the steel pipe of 3. Rust must be replaced, not to be used to build the frame.(2) the surface of the steel pipe shall be straight and smooth, and shall not be used for cracks, scars, delamination, dislocation, hard bending, burrs, indentation and deep drawing.(3) anti rust paint for steel pipe. Vertical rod and bar brush yellow rust proof paint, scissors and handrails with red and white tube brush. The maximum quality of each steel pipe shall not be greater than 25Kg. Steel pipe is strictly prohibited.

- Q:i just need to know the age limit with parental permission?

- I'm pretty sure it's 16-17 with parental permission. I suggest looking up some of the shops in your area and seeing what they say. There usually isn't a set rule for it, every shop is different. Like some shops may refuse seeing, say, a 14 year old, whereas another shop might do it with the parent's permission. Then of course, once you hit 18, you can do whatever you want, lol.

- Q:Does anyone know the name of the song or perhaps have a link to the video if they have seen it on net for example on youtube.?

- it is umm Ain's comin down til the sun comes down

- Q:would a scaffold piercing look gay on a guy?

- No i think that would be hott!!! :)

- Q:The role of the external scaffolding and the relevant provisions?

- There are many kinds of scaffolding, there are many types of scaffolding alone. According to the use, structure, decoration scaffolding scaffolding and protective scaffolding; according to the use of materials, there are bamboo scaffolding, scaffolding, metal scaffolding; according to the structure form, there are several independent bar type, frame type, bridge, hanging, hanging, pick style etc..

- Q:I think that'd be extremely entertaining.

- Because those guys are not talented at all and cause a lot of trouble for WWE and all the big names televised.

- Q:I want to get something pierced. My mom wont let me get anything on my face pierced but she will allow ear and body piercings. I thought about a belly ring but everyone has one amd i'm very skinny and scared it'd rip out. so i've been looking at ear piercings and really like a Targus piercing or a scaffold. But i don't know anything about them really. If you could which one is more painful, problems with them etc. please help, thank you

- If you want to be different AND have something that looks really cute, get a micro dermal. Either on your collar bone, or lower back dimples if you have cute ones! Good luck hun!

- Q:What does scaffold one's days mean? kill time?

- In 60 years of using English in Britain I have not come across that expression, so it is probably rare. Scaffolding is put up to help build or repair tall buildings, so possibly that expression means 'to do something useful with one's time.' But a scaffold is also, historically, a place of execution (legal killing of prisoner), so the expression could mean indeed 'wasting time'. I have a faint feeling that 'scaffold one's days' was written by a non-native speaker of British English. It may be more common in the USA.

- Q:I would like to ask how much scaffolding steel prices, scaffolding steel pipe use what are the requirements?

- Hello, you ask this question is not answered, you are building it, I am here to help you check a lot of information on the Internet, here to share with you, you can look at the reference price, the price there is no uniform standard, each region is different, the price is for reference only. Practice has proved that the new scaffold not only safe and reliable construction, installation speed, and the amount of steel scaffolding can be reduced to 33%, disassembly efficiency is improved by more than two times, the construction cost can be decreased, the construction site civilization, clean and tidy.

- Q:also apprx. what chapters is it in?

- The Democrats took decrease back a majority particularly through attacking Republicans on the unpopularity of the conflict and Bush's adverse approval rankings. there have been additionally various ethics scandals concerning republicans that twelve months that led to various of them resigning their seats and a regular loss of self belief that strengthened Democrat momentum. Tom postpone resigned after being charged with marketing campaign finance violations. He substitute into never convicted. Mark Foley sexually under pressure an underage male congressional website. The Abramoff indictment solid suspicion on all and sundry in Washington, extraordinarily those in ability. Scooter Libby substitute into Indicted. It substitute into basically a nasty twelve months to be a republican. a brilliant number of the scandals disappeared after the elections and became out to be not something. some indictments caught, and extremely, in basic terms as many democrats have been grimy as republicans. yet comparable to a corrupt regime helped positioned the democrats on top of issues. Then all their can provide to question Bush and end the conflict dwindled into not something as they took over the political equipment and grew to alter into as corrupt as a results of fact those they replaced.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Kwikstage Scaffolding System for Building Construction Project CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords