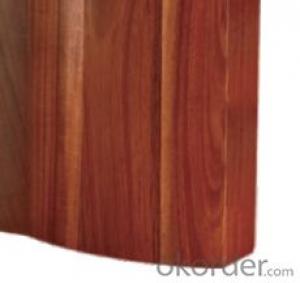

knife seat,F-KB015 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:0.964kg

MEAS:25*15*6.5cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q:How to use the left side of the knife knife thread?

- Right hand can be turned back to the processing of G92 is also G92, hope to adopt

- Q:CNC machine tool can be drilled hole how to center

- 1, do not need to set the coordinate system (the center), is loaded with a knife, in the process of preparation of processing requirements, reasonable adjust the height and verticality, the proper use of speed and feed rate, the knife tool can be set, simple, can fix a hole.2, if the degree of difficulty and high requirements, please use the circular drilling instructions programming.

- Q:How can we remove the NC turret

- First remove the inside, then the following,Two screws inside, then the eye, should use a punch, turn down

- Q:1, CNC horizontal lathe tool holder with front and rear respectively. CNC vertical lathe tool holder how to classify?2, no matter front or rear CNC lathe, cutter movement from right to left (along the Z axis) with G42 compensation?

- In the tip of the compensation bar to enter the radius of the tip of the knife is good, of course, we must first know the radius of the tip of the nose,

- Q:Why do you want to use the center frame and the tool holder when machining the slender shaft?

- When machining slender shafts, use the center frame and the tool holder for the following reasons:First, the use of the central support of the vehicle shaft1, the central frame is directly supported in the middle of the workpiece when the workpiece can be segmented, the center of the support in the middle of the workpiece, so that the support, L/d value reduced by half, slender shaft turning rigidity can be increased several times. Before the work piece is installed on the center frame, it must be in the middle part of the blank to produce a part of the support of the central support of the groove, the surface roughness and cylindricity error is small, otherwise it will affect the accuracy of the workpiece.Two, the use of the tool holder with the support of the fine axisWith the tool holder fixed on the bed saddle, there are generally two supporting claws, with the tool holder can follow the movement of the tool to offset radial cutting can increase the stiffness of the workpiece, reduce deformation. So as to improve the shape precision and reduce the surface roughness.According to the design principle of the tool holder, only two supporting claws can be used, because the cutting resistance of the lathe tool to the workpiece is F`r, the workpiece is stuck on the two supporting claws of the tool rest. But in actual use, the workpiece itself has a downward gravity, and bending workpiece inevitably therefore, when turning the workpiece, often due to centrifugal force instantaneous left supporting claw, a supporting claw contact vibration. If the three supporting claws are used to support the workpiece, the workpiece is supported by a lathe tool, so that the upper and the lower parts of the workpiece can not move, and the turning is stable, and the vibration is not easy to generate. Therefore, when the car is fine to find a very critical problem is to use the shaft with three claws.

- Q:CNC lathe hit the knife after the knife center height, how to deal with?

- Turret positioning pin deformation! Contact factory maintenance

- Q:The system is a wide number of 980TDb, lathe is the Yunnan machine tool factory. Whether it is a manual tool change or MDI way to enter the specified number of knives, the tool holder always turn around, until the emergence of PLC alarm 1000 change knife time is too long, A0000.0 knife can not reach the designated position. What the problem ah, I did not move the parameters of the machine, ah, this morning is good, work in the afternoon a boot on this.Back to the origin of the machine are abnormal, and can not return to the origin of the machine. Press the corresponding button after the machine does not respond, will not act. It's normal in the morning.

- I have encountered such a problem, the circuit has a capacitor breakdown, check the replacement can be.

- Q:How do you know how to install the roller skates?

- When installing tool holder is according to personal habits, but most were filled with the knife knife mounted on the middle sole. That is, the wheel is about the same length as the shoe.

- Q:The first reason is that the cutter shaft of the motor shaft is broken for a shaft / how long it will not be able to die!

- Open the cleaning to keep the knife holder into the garbage or not to check whether the motor is enough

- Q:CNC turret can be turned into 45 degrees ah? Can you turn counterclockwise?

- Numerical control machine tool holder can be numerically controlled turret also has an electric, hydraulic knife. CNC turret and part of the NC cutter can turn 45 degrees and counter clockwise. Part of the electric, hydraulic tool holder can not turn counterclockwise.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

knife seat,F-KB015 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords