KLB26-800 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

KLB20-600 Bored Pile Drilling Rig for Sale

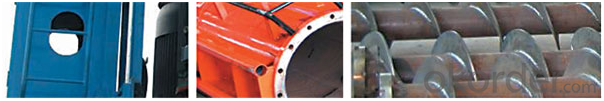

Product Features:

A Wide Choice Of Product: |

>>Our company is capable to manufacture various types of KL series drilling rigs. The max drilling depth could reach 20m to 34m.A wild range of products could be chosen for your practical needs. |

|

The column of the piling frame has two types, square and round. The former type applies back lift method. It is easily installed, safe and stable. The later type applies front lift method, the support rod will adjust itself when lifting the column. The column is higher, the drilling depth will go deeper. |

|

Higher Efficiency And Lower Consumption: |

>>The hydraulic system uses constant power variable design with low loss.The large flow, low failure rate, and high efficiency piston pump ensures the hydraulic components working well. |

|

high Reliability And Flexibility: |

>>The rotation system works with hydraulic flow. The rotating speed could be controlled to avoid impact. The failure rate is much reduced. The assistant hoist also uses hydraulic winch so the winding speed can be controlled at the operator’s will. Such design provides much convenience in the working process. |

|

Convenience In Dismantling, Transportation And Maintenance: |

>>With many years improvement and seeking for perfection, each part of the machine has well considered its convenience in dismantling, transportation and maintenance. The height and width of the largest part is designed within the range of transportatio lmits. |

|

Humanized Design: |

>>Much effort has been taken to increase the technical content on our products as well as humanized design. The machine is integrated with mechanical, electrical, hydraulic, and electronic devices. The appearance of the machine body, the comfort of the operator, the agility of the movements and so on are all well considered when designing the machine.Remote-control handle is optional due to the client's needs. |

|

Unique Design: |

>>After many years of experience in manufacturing the machine and analyzing feedbacks from our loyal clients, we made unique improvements in the easy-malfunction parts on the drilling rig: The bottom pillar of the column uses universal joint to enable the pole adjusted from left-right and front-back directions. The side support adjustment mechanism uses hydraulic motor instead of electrical motor which may affect the adjustment stroke or worm and gear which may shorten the life period. The supporting leg cylinder base uses large round box structure to avoid distortion at the working process. |

|

Multi-function: |

>>KL series is our new generation multi- function piling frame: with different power plant it can not only be used to do bored pile drilling or construct continuous wall by SMW method, but also do diesel hammer or hydraulic hammer pile driving. |

|

| KLB26-800 | ||

|---|---|---|

| Move method | Electro-hydraulic step | |

| Max drilling depth | 26m | |

| Max drilling diameter | φ800 | |

| Max output torque | 48.5KN·m | |

| Rod rotated speed | 23r/min | |

| Allowed lifting force | 400KN | |

| Power for power head | 55KWX2 | |

| Reductor of power head | ZZSH480 | |

| Leader size | φ630X8 | |

| Leader height | 31m | |

| Leader oriented center distance | 600Xφ102 | |

| Leader incline range | 5°front inclination 3°back inclination | |

| Stroke | 1.5m | |

| Climbing ability | <6° | |

| Rotary | Rotary way | Rotary motor |

| Rotary angle | ≤360° | |

| Rotary speed | 0~0.3 | |

| Main winch | Single pulling force | 5T |

| Increasing speed | 2.0/2.6/3.2 | |

| Motor power | 22KW | |

| Assist winch | Single pulling force | 2T |

| Increasing speed | 20m/min | |

| Motor power | 7.5KW | |

| Overall dimension(L*W) | 10m×5.2m | |

| Total weight(T) | 63T | |

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

- Q:How much power does piling work at a construction site?

- You see what device ah, various devices are not the same, but to remind you that the cable in piling time as far as possible with a point, otherwise it is easy to jump, because during each equipment operation at the same time, need a larger coefficient.

- Q:Rural housing foundation, piling machine generally can play how deep?

- In a spiral track Matlock advantage:1 、 simple operation, one hole forming,2, fast, 3-5 minutes can become holes 5 meters3, the maximum diameter of the hole 800mm, the maximum hole depth of 10m, suitable for housing construction, highway, high-speed rail slope protection and other pile foundation construction4, special, mobile convenient, 360 degrees of free rotation5, firewood and electricity dual-use, reduce cost expensesA Hui Omron caterpillar rotary drilling rig advantage:1, the fastest 20 minutes, you can dig 5-8 meters of earth drilling2, drilling can break strong weathering rock layer3, the well-known brand of the engine, "Yuchai, Weichai, fuel consumption of 40-50 yuan per hour.4 、 selection of multi-functional parts, such as: Clay bit, sand fishing drill, bottom drill bit, easy to change, practical.

- Q:Amd pile driver with motherboard, motherboard chipset is 970 or 990fx?

- 990FX prices higher, 970 lower prices.In addition to price factors, attention should also be paid to specifications, such as power supply and so on.

- Q:Piling of percussive drilling

- 7, the drilling process control should be rigorous, but also do not have to worry about failure, a reasonable choice of treatment methods, generally can be solved, the common, foot blade perforation, hole collapse, partial hole, cross hole, drilling, drilling, drilling buried crane, well preventive measures are generally not in advance, very important duty responsibility. 8, the remaining holes, steel cage decentralization, concrete pouring, sealing and other are more conventional, do not write more. But the bottom of the hole, sediment, sediment, etc. must be recycled clean, otherwise it will be buried in the later works of greater risk. When the concrete is poured, the bottom concrete under the impact of residue inclusion in steel or bond caused by defects in the pile in concrete, on the upper structure of the load transfer to the bottom of the pile, the structure will definitely should produce uneven settlement for residue.

- Q:I'm a rural resident, close to the town;A building will be built behind my house and the pile driver is only 10 meters away from my house..Although the use of hydraulic pile driver, there is no sound like that. There was no sound at all, but every time they moved the pile, it was going to be a big shock, and my house was shaking badly. I'm very upset, and I don't know if there is any influence on the house, the dirt and the ground because of the driving at such a short distance..My country's rural housing is three storey building, two house facade, 8 meters wide or so, built in 92 years.So I specifically asked about the laws and regulations on the construction of pile driving and future formal construction of the surrounding residential housing what protective provisions?Thank you

- You should say is static pressure pile, is the smallest influence of all the filling pile, if it is immersed pipe pile will not, the safety distance is 28 meters

- Q:How many tons of pile drivers are used to hit 400X400 square piles?

- Usually with 6.3 ton or 8.3 tons of guide rod, diesel hammer will be able to hit. The static pile machine is not clear.

- Q:What's the difference between a amd bulldozer and a pile driver?

- when processing the CPU performance when sharing CPU acceleration, when GPU needs to deal with a large amount of card game when the bias display processing GPU side to speed up, so some complete performanceFor example, I have 2 truck drivers and night driving (which has a driver is spare Porter and 2 part-time drivers) at Porter, I drove with the driver, I can call a driver when handling spare porters so I have 3, this is called distribution acceleration, rational use

- Q:What is a car pile driver? I hear it's easy to use.

- Yeah, yeah. You're talking about wheels. I am now using a wheeled screw, not only easy to move, the speed is very fast, is a powerful brand of Shandong piling machine, also known as force pile driver.

- Q:Is the architecture of the pile driver strong in single core performance or multi - core capability? Or?

- Compared to the K10.5, the performance of bulldozers and pile drivers did not rise or even decline.Multicore is stronger because it's simple - more nuclear......

- Q:What is the noise level of site construction (piling)?

- The structure of phase, daytime noise limit is 70 dB, the night noise limit is 55 dBThe decoration stage, daytime noise limit is 65 dB, the night noise limit is 55 dBThe daytime generally refers to 7:00 in the morning to 23:00 at night, the night usually 23:00 to 7 o'clock in the morning.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

KLB26-800 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords