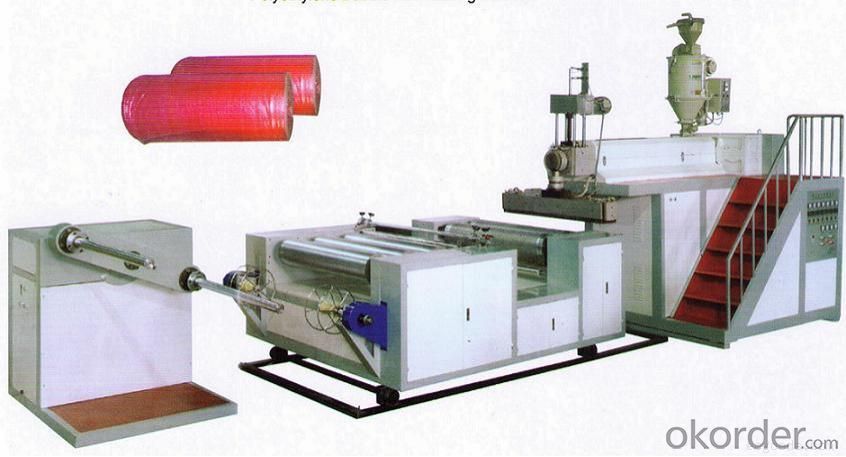

JSM Polyethylene Bubble Film Making Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STRUCTURE FEATURES:

This machine adopts once-through shaping technique, thus has high efficiency and excellent product quality. This machine set has such features as scientific and reasonable structure design, Smooth and reliable running and convenient operation and maintenance.

Polyethylene air-cushion film is a kind of packing materials which has been widely used at present. It not only has good cushioning effect, shock resistance and heat-sealing performance, but also has such advantages as good corrosion resistance and transparency, etc. So it has been widely used for packing, household wares, post parcel, precise instrument, bicycle, polyurethane furniture, etc.

TECHNICAL PARAMETER:

Model | JSM-650 | JSM-1000 | JSM-1200 | JSM-1500 | JSM-2000 |

Screw Diameter | Φ55mm | Φ60mm | Φ65mm | Φ80mm | Φ90mm |

Film Width | 650mm | 1000mm | 1200mm | 1500mm | 2000mm |

Max. Output | 25kg/h | 40kg/h | 50kg/h | 65kg/h | 80kg/h |

Main Motor Power | 11kw | 15kw | 18.5kw | 22kw | 37kw |

Power | 30kw | 48kw | 55kw | 70kw | 105kw |

L/D | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 |

Power Supply | 380/3/4/50 (Volt/Ph/Line/Hz) | ||||

Weight | 3500kg | 4000kg | 4200kg | 4500kg | 7000kg |

Overall Dimension (L*W*H) | 9.0×3.0×2.5m | 9.0×3.0×2.5m | 9.5×3.8×2.5m | 10×4.0×2.6m | 11.5×4.8×4.0m |

FAQ:

Where is your factory located:

Our production base is located in Zhejing Province.

Will your side be responsible for installation, is it for free?

We will be in charge of installation, but you have to pay related fee.

What is the advantage of your company?

Our company is the largest building materials and equipment suppplier in China, second in the world, as a state-owned company, we strictly focus on quality management, our production is under the standard of IS0 9001. for the more, we have experienced logistic team, which is responsible for puntual deilivery and cheapes shipping charge.

- Q:extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately.

- Q:Extrusion machine operating procedures, specific points, thank you!

- 1, operators must be familiar with the procedures, the safety test qualified, wear good protective equipment, shall operate the equipment.2 when the power is on, check whether the thermal control of the electric appliance is sensitive and reliable, whether the thermocouple indicates the temperature is correct or not, and if there is a problem, please repair the personnel to exclude them.3 when driving, should check the main reducer, traction non polar transmission, the line is stepless gear box lubrication is normal, fan ventilation is good.4 before driving, pay attention to the heating temperature of each section, whether the actual temperature required by the process, the heat preservation time should be enough, and the initial heating time can not be less than 3 hours heat preservation.5, not in the plastic bad, scorched, aging, extrusion production, in case of accidents, and found the above problems, immediately try to rule out.

- Q:Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q:Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q:Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q:The working principle of an extruder

- The material is moved forward by the extrusion of the screw and the barrel, and the material is fully homogeneous and plasticized in the process of material advance. Then the material is extruded by a certain shape of the die by the die of the die.

- Q:Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q:What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q:1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q:Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JSM Polyethylene Bubble Film Making Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords