JSM-Automatic Drainage Plate Rolling Suction Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stracture Features

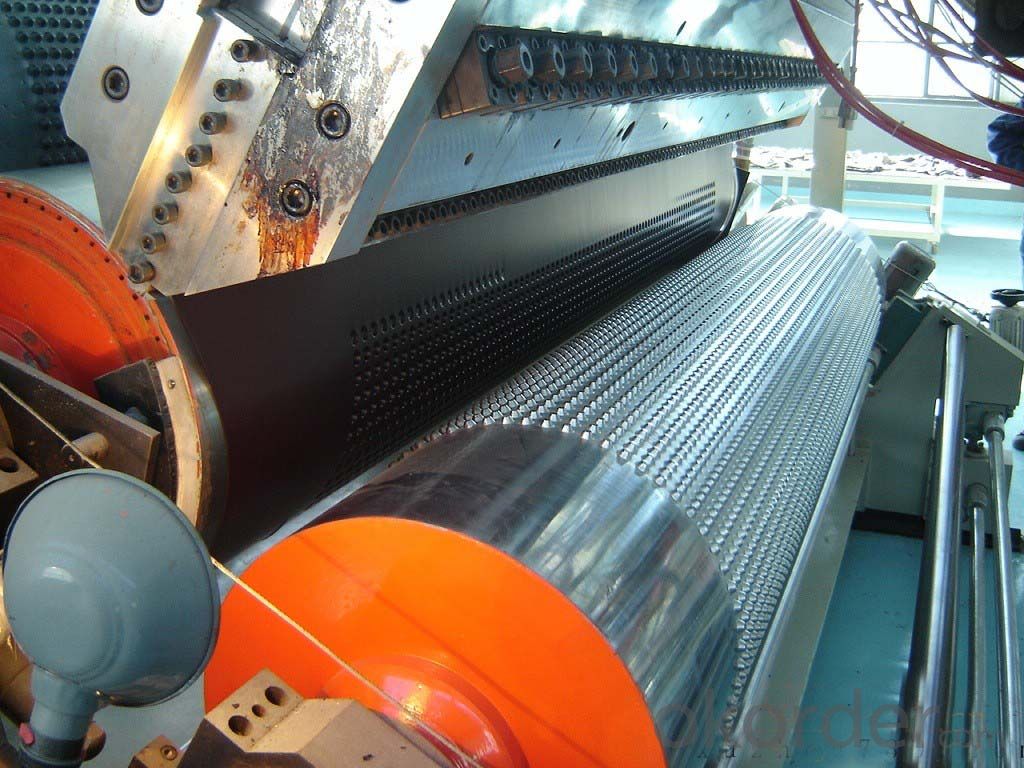

PE Drainage Board Rolling Suction Machine is an innovative machinery in China. Compared with the old-fashioned forming process, this equipment forms a whole continuous sheet of drainage board at one time with high efficiency, low energy consumption. It also solved the problem that the compression strength of old rolling forming drainage sheet is not ideal. After unique mechanics design, the convex wall thickness of the circular convex on the drainage board is well-proportioned. Meanwhile, the compression strength is over 50% higher than similar products which solve the problem that the compression strength of domestic drainage board made of HDPE is not ideal and ensures long-term loaded compression tolerance. Plastic drainage board is a kind of multi-functional membrane coiled materials performing comprehensive protection, professional waterproofing and drainage. Its quality is up to the international advanced level, completely changes the situation that high-quality drainage board can only rely on import. All the equipments, from the calendars, tractor to the rolling machine, are all especially designed and manufactured based on the structure of drainage board. The thickness range of the output board is 0.5mm-5.5mm, width up to 5000mm.

Specification:

1. Raw Materials: High-low pressure PE Mater-batch.

2. Equipment configuration (3000 width).

(1) Master-batch Mixer: Mixed volume:300L, Mixed ability: 500kgs/h, Mixed Power:3Kw.

(2) Automatic Loading Machine: Motor power: 1.1kw, Loading capacity:500kgs/h

(3) Singly Screw Extrusion Machine.

Screw Diameter: 150m; Length – Diameter Ratio: 30:1; Screw Rotate Speed: 0-75rpm

Main Motor Power: 160KW; Frequency Conversion Speed Modulation Method: variable frequency motor, Taiwan frequency converter.

Heating Power: about 80kw; Extrusion alibity: 300-800kg/h

Heating Circle: Multistate-cast-aluminum heating circle; Screw Nut Material: 38CrMoAl Nitriding Treatment.

Nitriding Depth: 0.4-0.7mm Nitriding Rididity: HV720-940

Electric Control Cabinet: Omron Temperature Control, LG Surrenttra Former Contactor.

(4) Handmade Ring Screen or Oil Pressure Screen Exchanger (Optional)

(5) Clothes-rack shape Flat Mould, Chrome-faced treatment.

(6) Forming Roller: available form diameter is about 700-800mm; Length is 3300mm.

(7) Traction: Taiwan frequency converter, Frequency conversion speed modulation.

FAQ:

Where is your factory located:

Our production base is located in Zhejing Province.

Will your side be responsible for installation, is it for free?

We will be in charge of installation, but you have to pay related fee.

What is the advantage of your company?

Our company is the largest building materials and equipment suppplier in China, second in the world, as a state-owned company, we strictly focus on quality management, our production is under the standard of IS0 9001. for the more, we have experienced logistic team, which is responsible for puntual deilivery and cheapes shipping charge.

- Q:extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately. Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q:What raw material does the extruder use?

- Control science and EngineeringJob: in gender: Male College: College of mechanical and power engineering representative paper: melt rotating twin screw extruder in conveying flow solving teaching: research direction: mainly engaged in polymer material processingLinear low density polyethylene (LLDPE) linear low density polyethylene (LLDPE) linear low density polyethylene is structurally different from the generallow density polyethylene

- Q:Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q:Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q:How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

- Q:What is an extruder?

- This method of forming is continuous molding, such as pipes, plastic profiles, films and so onThe machine also has a single screw, twin-screw, multi screw points.The forming methods are single extrusion and coextrusion only.

- Q:Extrusion blow molding machine, storage or continuous type good?

- The amount of extrusion must be continuous, efficient, and wasteful

- Q:What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q:Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q:Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- One is the use of frequency converter connection, in accordance with the frequency converter user manual guidance method to adjust the speed, in addition to the use of electromagnetic speed control motor, through the speed box above potentiometer adjust speed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JSM-Automatic Drainage Plate Rolling Suction Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords