JPN1000 Automatic Piston Filling Machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

- Option:

- (L)3000mm X (W)1100mm X (H)1770mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Introduction

1.1 Servo Drive System

JPACK’s volumetric filling system exclusively uses the delicate servo drive system to control the main filling structure to achieve the high stability and precise positioning

1.2 Vertical Driven Piston

The vertical stroke of the filling piston movement adopts with our exclusive servo control system provides not only the long term energy saving result but also effectively create a great result of machine load rate reducing

1.3 Tool-Free Adjustment

Tool-free production change when changing the filling volume; by key-in the desire number on the PLC gives users the best time saving result.

The delicate servo control system design can provide choice of above liquid surface filling, underneath liquid filling and bottle neck (opening) filling accordingly with different features of liquids.

1.4 High Accuracy

The delicate servo system precisely control the filling amount with precise piston stoke provides high filling accuracy, intelligent piston is designed with miner adjusting mechanism enable users to adhesive ultimate higher accuracy.

High Adapability

This filling machine is widely used for food, pharmaceutical, chemical, cosmetics and various industries.

The personalized control panel system provides users an easy operation and an effective management result by production monitoring on the PLC.

2、Feature

2.1 Controlled by Panasonic servo system.

2.2 Controllable and various filling speed.

2.3 Accurate to ±0.5% ( with drinking water )

2.4 Integrated digital control with Siemens PLC and Hi-tech Touch Screen controls for easy operation.

2.5 Designed for easy change-over and cleaning.

2.6 Professional manufacturing techniques using ISO-9001 system.

2.7 Sturdy conveyer system driven by motor. Adjustable conveyor guide rails to accommodate with different products.

GMP standard Stainless Steel.

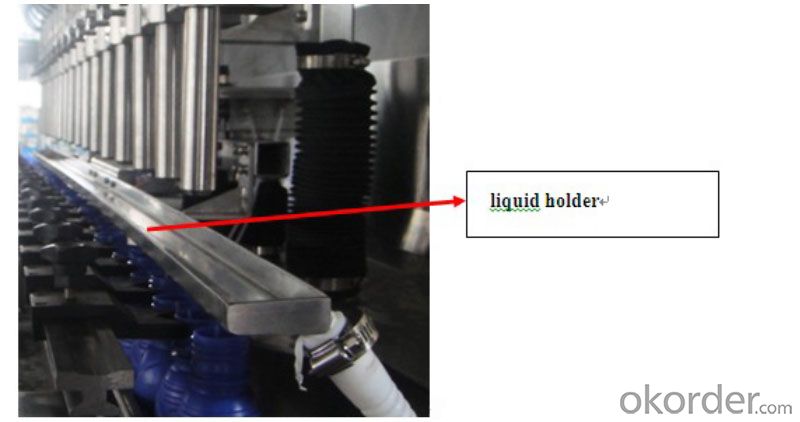

2.8 Bottle holding mechanism for the best position of the bottles before filling action.

2.9 No bottle-no fill system.

2.10 Bottle jammed detection.

2.11 Warning light and buzz alarm to inform operator production error.

2.12 Filling zone protected by interlock guards for safety registration

2.13 ABB circuit breaker for the protection when overload.

Memory slots for storing filling parameters for future operation

2.14 Easy to install and operate, it only requires minimum maintenance for maximum performance and a long filler life time.

2.15 Quick change of volume with digital readout.

Delicate filler structure and finish comparable with European machines.

2.16 Volume set can be changed on the touch screen. Filling pistons are controlled by servo system.

2.17 Individual piston adjustment for fine tuning.

2.18 Digital control system to enable multiple filling actions on the same bottle for double, triple and more.

2.19 Fully automatic rise for nozzles, adjustment can be done on touch screen

2.20 Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling of foamy liquids.

2.21 Adjustable speed while filling, it can fill slowly at the beginning and then accelerate to faster speed, finally slow down once again to finish up. This can prevent foamy liquids from bubbling and avoid spillage.

3、Specifications

3.1 Filling Capacity Options: 100cc—1000cc

3.2 Liquid Contact Part Material Option: Stainless Steel 304/316L

3.3 Supply Voltage:220V, 50-60Hz, 1Phase

3.4 Power Consumption: 1.5 kW

3.5 Air Pressure: 6-8kg

3.6 Dimension: (L)3000mm X (W)1100mm X (H)1770mm

3.7 Net Weight: 850kg

3.8 Filling Nozzle:4/6/8/12/16/20

4、Electrical configuration

4.1 PLC:GERMANY SIEMENS

4.2 HMI:GERMANY SIEMENS

4.3 Servo System:Japan Panasonic

4.4 Sensor:Japan OPTEX

4.5 Frequency Converter:Japan Panasonic

4.6 Power Switch:France Schneider

4.7 Solenoid valve: TAIWAN CHELIC

4.8 Low voltage electrical appliances:France Schneider

5、Images

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q:What material or paper should I use for high-grade packaging?!

- Wood may be consideredIf you want to choose paperYou may consider mounting special paper with 1200g-1600g Grey Board (or 3-5 foil board). There are many kinds of special paper

- Q:What packing materials should be understood in purchasing?

- Other specific products, specific problems specific analysis, because the product form is not the same, liquid or chemical products packaging is not the same, the general small commodities, daily necessities of packaging almost the same

- Q:What plastic packaged food is safer?

- If you do not want to contact the high temperature, you can also choose PET materials and PS materials, these two can contact food directly.

- Q:Cookies with tinplate packaging has what advantage

- Mature technology and high production efficiency: the production of tinplate has a long history, mature technology is a set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q:What are the categories of packing materials?

- Composite soft packing material: soft packaging, film, core wire, aluminum foil composite film, vacuum aluminum plating paper, composite film, composite paper, BOPP; metal packaging materials: tin foil, strip, hoop, packing buckle, Blister aluminum, aluminum foil, aluminum plate, steel buckle PTP;

- Q:What are the sales packing materials?

- Sales packing is also called inner packing or small package. Is the direct contact with the goods and goods into retail outlets and consumers or users directly to meet the packaging. Adapt to the competition in the commodity market and meet the multi-level consumption requirements, and constantly send to the sales packaging requirements, improvement and innovation information. This information is not only for the sales package, but also refers to the packaging industry; no synchronous development of each professional packaging and improve sales package will be in the "bricks without straw" situation.

- Q:What is accessory material? What is the difference between it and raw material?

- From this we can see that the auxiliary material is one of the raw materials and belongs to the raw material.For example: to make green pepper fried meat, then oil, salt, sauce, vinegar and other spices are auxiliary materials, and green peppers and meat is the raw material or main material, but they are the raw materials for stir frying.

- Q:Billycan what are the advantages compared with other packaging materials?

- Barrier: tinplate cans have excellent barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products.

- Q:What can I do instead of the carton packing now?

- There is no substitute for carton at the moment.As far as the price is concerned, cartons are cheaper to pack than foam, plastic and wooden boxes.From the degree of environmental protection, carton packaging is easy to degrade, more environmentally friendly than other packaging.

- Q:What's bread packing? Polyethylene film, waterproof cellophane, etc.

- BOPP (biaxially oriented polypropylene), //VMCPP (aluminized cast polypropylene) or PET (biaxially stretched polyester film), //VMCPP (aluminium plated cast polypropylene), exactly the same as what was said upstairs, two, just like that.Carton: carton with various specifications, 3.5.7.9.11, K type, W type, A type, B type, C type, E type, F type, B3B pit paper, Taiwan yellow K paper. The angle of paper available in cartons with additional protection, fixed on the tray outside angle, the cushioning edge protection reinforcement effect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JPN1000 Automatic Piston Filling Machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

- Option:

- (L)3000mm X (W)1100mm X (H)1770mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords