JLP-120 Automatic Bottle Unscrambler

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product ShortDesc:

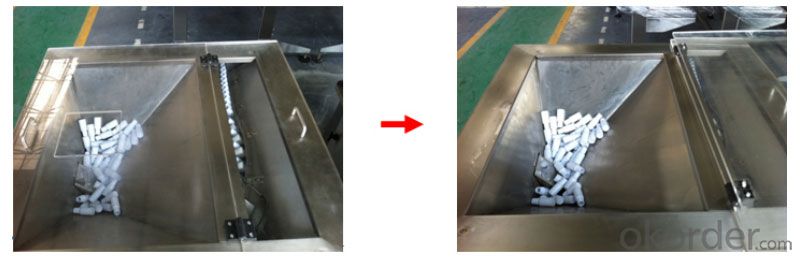

JLP-120 Automatic Bottle Unscrambler is making up of the bottle holder, unscrambling plate and bottle stand. It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will be in the filling line in order. The machine has the features of simple structure, easy operation and good stability.

2、Product Details

JLP-120 Automatic Bottle Unscrambler is making up of the bottle holder, unscrambling plate and bottle stand. It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will be in the filling line in order. The machine has the features of simple structure, easy operation and good stability. It can reduce the labor force. It is your ideal choice for unscrambling the small bottles.

3、Features

3.1 Bottle Holder

3.2 Bottle Unscrambling Structure

Simple structure and easy operation

3.3 Automatic Control

Complete control function, easy operation. It uses frequency converter to control the bottle unscrambling speed.

3.4 Automatic Coordination Function

The machine has the automatic coordination function. When the sensor checks the jam before the filling machine ,the bottle unscrambler will stop. After the jam problem solves, it will restart working.

4、Main Technology Parameter

4.1 Applicable Bottle Size:10-200ml Round, Flat Bottle

4.2 Bottle Diameter:Ø20-40mm

4.3 Capacity:≤120 bottles/hour

4.4 Power:0.5Kw

4.5 Power Source:220V 50Hz

4.6 Amount of Air-consuming : 0.3m³/min

4.7 Weight:350㎏

4.8 External Dimension:900×900×1200(mm)

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q:What's the difference between the materials used in kraft paper packaging?

- The whole paper pulp kraft paper packaging: tension is very good, do not pull off, the color will be very uniform, is also very resistant to wear if you need outside packaging printing LOGO what, it can use kraft wrapping paper wood pulp, wood pulp and kraft wrapping paper printed very well.

- Q:Paper bags, milk and plastic bags. What's the difference between milk and paper bags?

- Plastic bags - aseptic plastic bags are specially treated with a black coating inside the plastic bag, which serves as a barrier to light. However, due to the relatively thin plastic bags, even after special treatment, the effect of isolation of light can not be compared with aluminum foil, so the normal temperature guarantee period of milk is about 30 days.

- Q:Is the antistatic value of PS material (or other packing material) as small as possible?

- Not necessarily. This needs to be decided in terms of specific areas of use and requirements.The so-called antistatic refers to reach 10 between the 7-10 sides.And the 1-6 side of the 10 is generally referred to as electrical conduction.

- Q:What are biodegradable packaging materials?

- Biodegradable packaging has a bright future and has attracted worldwide attention. In this paper, the properties, degradation mechanism, processing technology and application of various kinds of degradable packaging materials are reviewed. According to the mechanism of degradation, it can be divided into biodegradable plastics, biodegradable plastics, light / biological double degradable plastics and water degradation plastics.

- Q:What are the commonly used packing materials?

- Composite flexible packing material: flexible package, aluminium plated film, aluminum foil composite film, vacuum aluminized paper, composite film, composite paper, BOPP

- Q:How many kinds of packing are there?

- According to the packaging technology, there are: shockproof packaging, moisture-proof packaging, anti rust packaging, anti mildew packaging, etc.;9., according to the packaging structure classification: body packing, blister packaging, heat shrinkable packaging, portable packaging, pallet packaging, combination packaging, etc..

- Q:What are the categories of packing materials?

- Plastic packing material: PP packing belt, PET packing belt, tearing film, winding film, sealing tape, heat shrinkable film, plastic film and hollow board;

- Q:How to prevent the use of packaging materials during production without error?

- I don't know what kind of package material the landlord says1. place the required packages and other materials separately and mark them well2. educate and train operators!3. make a comparison of the material used for the package with the remaining material and the product being produced daily to see if they are consistent4. check in before you check in

- Q:What are the sales packing materials?

- Sales of packaging materials are generally an ordinary white paper, copy paper, crepe paper, bubble paper, poly velvet, pearl cotton, sponge, plastic bags PP, PE, OPP, PVC, PVA, shrink film (PE and PP).

- Q:What are the packing materials for heavy cargo transportation?

- The bulky goods need to use fixed bandages, tie belt, to prevent the occurrence of collision in the process of transportation, damage. Dragon Century Logistics has made big transport in Hongkong, and the handling and strengthening of large cargo before shipment are more mature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JLP-120 Automatic Bottle Unscrambler

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords