JIS Standard Structural Steel H-beam all Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offeringJIS Standard Structural Steel H-beam at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's JIS Standard Structural Steel H-beam are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

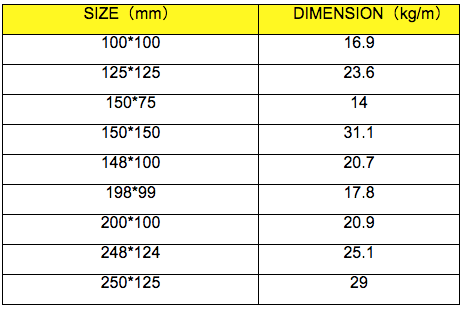

Specifications of JIS Standard Structural Steel H-beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of JIS Standard Structural Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of JIS Standard Structural Steel H-beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of JIS Standard Structural Steel H-beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:Are Steel H-Beams suitable for art or cultural facility construction?

- Indeed, art or cultural facility construction can benefit from the use of Steel H-Beams. Given their robustness and resilience, Steel H-Beams have become widely adopted in the construction industry. Their exceptional ability to provide support and stability makes them particularly well-suited for the creation of expansive structures like art galleries, museums, and cultural facilities. Moreover, Steel H-Beams can be easily customized and fabricated to meet specific design criteria, thereby facilitating flexibility and innovation in the construction of artistic and cultural spaces. The adaptability of Steel H-Beams, coupled with their capacity to withstand substantial loads and withstand the elements, renders them a dependable option for the development of art and cultural facilities.

- Q:What are the different types of steel used for manufacturing H-beams?

- There are several different types of steel that are commonly used for manufacturing H-beams. The selection of the steel type depends on various factors such as the required strength, durability, and cost-effectiveness for the specific application. 1. Carbon Steel: This is the most common type of steel used in H-beam manufacturing. It contains mostly iron and carbon, with small amounts of other elements. Carbon steel is known for its high strength and affordability, making it a popular choice for a wide range of applications. 2. Alloy Steel: Alloy steel is a type of steel that contains additional alloying elements such as chromium, nickel, or molybdenum. These elements enhance the steel's strength, hardness, and resistance to corrosion. Alloy steel H-beams are frequently used in heavy-duty construction projects or applications that require exceptional strength. 3. Stainless Steel: Stainless steel is a type of steel that contains a minimum of 10.5% chromium, which gives it excellent resistance to corrosion and staining. H-beams made from stainless steel are commonly used in applications where hygiene, durability, and aesthetic appeal are critical, such as in the food industry or architectural structures. 4. High-strength Low-alloy (HSLA) Steel: HSLA steel is a type of steel that provides high strength and improved toughness compared to standard carbon steel. It often contains small amounts of alloying elements such as vanadium, niobium, or titanium, which enhance its mechanical properties. HSLA steel H-beams are commonly used in applications that require high strength-to-weight ratio, such as bridges or heavy machinery. 5. Weathering Steel: Weathering steel, also known as Corten steel, is a type of steel that develops a protective layer of rust when exposed to the elements. This layer acts as a barrier against further corrosion and eliminates the need for painting or maintenance. Weathering steel H-beams are often utilized in outdoor structures like bridges or sculptures. It is essential to select the appropriate type of steel for manufacturing H-beams based on the specific requirements of the project, considering factors such as strength, durability, corrosion resistance, and cost-effectiveness.

- Q:Do steel H-beams require additional bracing?

- Yes, steel H-beams typically require additional bracing to provide stability and prevent buckling or lateral movement under load.

- Q:Are Steel H-Beams resistant to UV radiation or fading?

- UV radiation and fading are not things that steel H-beams naturally resist. Carbon steel, the primary material used in constructing steel H-beams, lacks inherent UV resistance. When exposed to UV radiation over time, the steel can undergo oxidation, leading to rust formation and eventual material degradation. To safeguard steel H-beams from UV radiation and fading, manufacturers often use protective coatings like paint or galvanization. These coatings create a barrier between the steel and UV radiation, preventing direct contact and reducing the risk of fading or degradation. However, it's important to note that these protective coatings may require regular maintenance and reapplication to ensure long-term protection against UV radiation. Furthermore, external factors like climate, humidity levels, and the intensity of UV exposure can impact the rate at which steel H-beams fade or degrade due to UV radiation. Regular inspection and maintenance can help detect any signs of fading or degradation in steel H-beams, allowing for timely repairs or replacements to uphold their structural integrity.

- Q:What are the applications of steel H-beams in the automotive industry?

- Steel H-beams have various applications in the automotive industry. They are commonly used in the construction of vehicle frames and chassis due to their high strength, stiffness, and durability. H-beams provide structural support and help distribute the weight and forces evenly, enhancing the overall stability and safety of the vehicle. Additionally, their lightweight nature allows for improved fuel efficiency and reduced emissions. These beams are also utilized in the manufacturing of heavy-duty trucks, buses, and off-road vehicles where the demand for load-bearing capacity is high. Overall, steel H-beams play a crucial role in enhancing the structural integrity and performance of vehicles in the automotive industry.

- Q:Can steel H-beams be used for mezzanine floors?

- Yes, steel H-beams can be used for mezzanine floors. Steel H-beams are commonly used in construction for their strength and load-bearing capabilities. Mezzanine floors are typically added to existing structures to create additional usable space, and steel H-beams provide the necessary support for the floor. They can withstand heavy loads and distribute the weight evenly, making them suitable for mezzanine floor construction. Additionally, steel H-beams are durable and long-lasting, ensuring the stability and safety of the mezzanine floor.

- Q:Can steel H-beams be used in mezzanine or elevated flooring systems?

- Yes, steel H-beams can be used in mezzanine or elevated flooring systems. Steel H-beams provide strong structural support and are commonly used in construction for their durability and load-bearing capabilities. They are suitable for creating stable and secure elevated platforms such as mezzanines or flooring systems.

- Q:Are steel H-beams resistant to electromagnetic interference?

- Steel H-beams, which are commonly utilized in construction due to their strength and load-bearing capabilities, do not possess inherent properties that grant them resistance against electromagnetic interference (EMI). Nevertheless, it is vital to acknowledge that the extent of interference encountered will be influenced by several factors, including the steel's thickness, the existence of other materials or coatings, and the intensity and frequency of the electromagnetic waves. To alleviate the impact of electromagnetic interference, a variety of techniques can be employed. These may involve the utilization of shielding materials, the application of coatings or insulators, or the implementation of appropriate grounding and bonding techniques. By employing these measures, the adverse effects of EMI on steel H-beams and the structures they are integrated into can be effectively diminished.

- Q:What are the differences between hot-rolled and cold-formed steel H-beams?

- Hot-rolled and cold-formed steel H-beams are two commonly used structural steel products that have distinct differences in their manufacturing processes and properties. Firstly, the manufacturing process for hot-rolled H-beams involves heating a steel billet or slab above its recrystallization temperature and then passing it through a series of rollers to shape it into the desired H-beam profile. This process results in a finished product with a rough surface texture and a scaled outer layer. In contrast, cold-formed H-beams are produced by bending and shaping steel sheets or strips at room temperature, typically through a series of rollers or press brakes. This method produces a smoother surface finish and eliminates the need for scaling. In terms of their properties, hot-rolled H-beams tend to have higher strength and load-bearing capacity compared to cold-formed H-beams. This is due to the structural changes that occur during the hot-rolling process, which refine the grain structure of the steel and increase its overall toughness. Cold-formed H-beams, on the other hand, have a higher degree of dimensional accuracy and consistency due to the precise shaping and bending process. This makes them suitable for applications where precise measurements and tight tolerances are required. Another significant difference lies in their cost and availability. Hot-rolled H-beams are generally more readily available and cost-effective compared to cold-formed H-beams. The hot-rolling process is faster and more efficient, allowing for larger production volumes and lower production costs. Cold-formed H-beams, on the other hand, may require additional processing and fabrication steps, which can increase their overall cost. In summary, the main differences between hot-rolled and cold-formed steel H-beams lie in their manufacturing processes, surface finish, properties, and cost. Hot-rolled H-beams offer higher strength and load-bearing capacity, while cold-formed H-beams provide greater dimensional accuracy and consistency. The choice between the two depends on the specific requirements of the project, including budget, structural needs, and aesthetic considerations.

- Q:Calculation method of H steel area

- It's about 1.74 square meters. The price of the material is about 5100 yuan / ton

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JIS Standard Structural Steel H-beam all Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords