Jinnuo Construction Hoist Motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Jinnuo Construction Hoist Motor

Product Details

Basic Info.

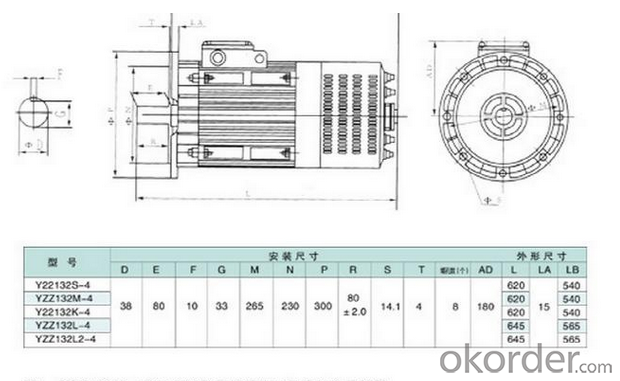

Model NO.:11KW 15KW 18KW

Type:Lifting Platform

Application:Construction Usage

Sling Type:Wire Rope

Power Source:Electric

Certification:ISO9001: 2000

Condition:New

Brand:Jinnuo

Export Markets:Global

Additional Info.

Packing:Wooden Case

Standard:SGS

Origin:Shanghai

Production Capacity:20000

Product Description

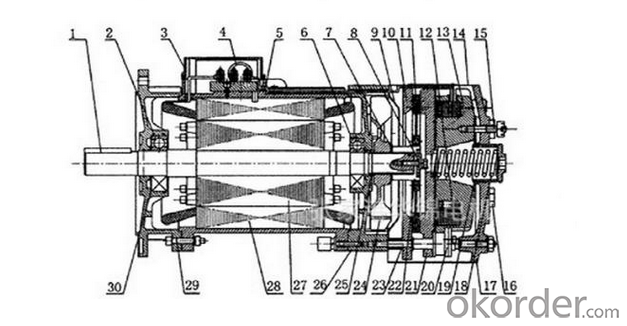

Appearance design: beautiful modelling concise;Brake wear hidden inside lead;Plug in type electromagnetic wire;Double rings seat design.

Internal performance: joint construction lifter actual working condition, internal reflect similar domestic leading level of the motor performance.

Embodied in: rated voltage 85% when can full load starting;Rated load 125% when relaxed starting and stable operation;Can be moderately happy to meet the demand of the brake adjustment;Frictionless operation of the brake disc structure to get higher running stability, low noise and high the whole life.

Reliability: the friction brake disc 12 months, the average life expectancy of armature and fixed brake disc life expectancy for 30 months, brake trouble-free working times, 200000 times on average, trouble-free working time is an average of 18 months;Motor can be selected embedded type thermal protection device, ensure reliable motor thermal overload protection.Interchangeability and maintainability: motor and DC brake

- Q:What are the main differences between a stepper motor and an ordinary motor?

- Stepper motor is relatively better to control the motor rotation of an angle, and the ordinary motor is often only speed regulation, but it can not like stepper motor, according to your request and walk a relative distance.

- Q:How to control the displacement and speed of the stepping motor?

- 2, the 28BYJ48 5V driver is KINGBOX supporting the 4 phase 5 wire stepper motor, and deceleration stepper motor.The speed reduction ratio is 1:64, and the stepping angle is 5.625/64 degrees. If you need to turn 1 circles, then you need360/5.625*64=4096 pulse signals.

- Q:What are the meanings of stepper motors unipolar and bipolar? What are the differences between the four wire bipolar motors?

- Bipolar: Bipolar not only turns several windings in turn, but also changes the direction of the current in the windingSuch as four wire bipolar motors, there are two windings, A and B,The ends of A winding are A1 and A2 respectively, and the ends of B are B1 and B2. respectivelyMode of operation: A1, A2-----B1, B2-----A2, A1-----B2, B1-----A1, A2-----

- Q:What is the maximum speed per minute of the 42 stepper motor?

- Referred to as "step angle", its rotation is running at a fixed angle, step by step. Number of pulses can be controlled by controlling the angular displacement, so as to achieve the purpose of accurate positioning; at the same time by controlling the pulse frequency to control the motor rotation speed and acceleration, so as to achieve the purpose of speed.

- Q:How to overcome the vibration and noise of two phase hybrid stepping motor in low speed operation?

- The vibration and noise of stepping motor at low speed are its inherent disadvantages, and the following methods can be used to overcome them:A., such as stepping motors, work just in resonance, avoiding mechanical resonances by varying mechanical ratios such as speed reduction;B. uses a drive with subdivision functions, which is the most common and easiest way to do so;

- Q:Will this stepper motor driver can be directly connected to the 5V microcontroller IO port control?

- In general, such stepper motor uses 12-24V DC control, and its DIR, PULSE and EN signals can be directly driven by the microcontroller IO port

- Q:Can the speed of the stepping motor reach the speed of the embroidery of the sewing machine or embroidery machine? I use the permanent magnetinduction four stepper motor step angle is 0.9/1.8, I use the whole / half step motor can drive when idling, but with fixed load, with 1600 segments of the driver can drive the load, but too slow, I don't know the maximum speed of the stepper motor can achieve the how much and how to use the whole / half step drive motor can drive the rotation speed to load? Is related with motor model and driver or related? My singlechip program is simple, that is, in the main program cycle, so that the motor in the same direction.

- According to a large number of tests, the commonly used hybrid stepper motor speed in 500RPM can keep close to the motor torque, of course, this is not absolute, some more, some less, have a great relationship with the motor itself characteristic and connection mode. So it is generally recommended to look at the motor torque frequency curve, and then make a choice.

- Q:How to understand the number of stepper motors?

- I can list the motors in different phases, and I would like to make a list of them1, two-phase motor: the lead line can be 4 or 82 and four phase motors: the lead line can be 5, 6 or 83, three-phase motor: the lead line can be 3 or 64 and five phase motors: the lead line can be 5, 6 or 10

- Q:Stepper motor stepper angle is 1.8 degrees, the driver is subdivided into 6400step/rev. How many pulse signals does it take to turn around?

- The subdivision drive is of high accuracy. The subdivision is a drive that divides each pulse emitted by the superior device into a factor of pulse output according to the subdivision factor set by the driver

- Q:The stepper motor drive, synchronous belt drive, the stepping motor is arranged in a lateral hanging on the plate, moving vibration noise is large, is also great, (have adopted 8 subdivision driver of the specific installation see picture)

- Too many connections, that is, your aluminum plate and other pieces connected too much, or suspension of the design should consider

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Jinnuo Construction Hoist Motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords