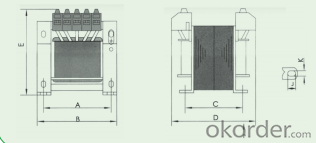

JBK1 transformer high voltage transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

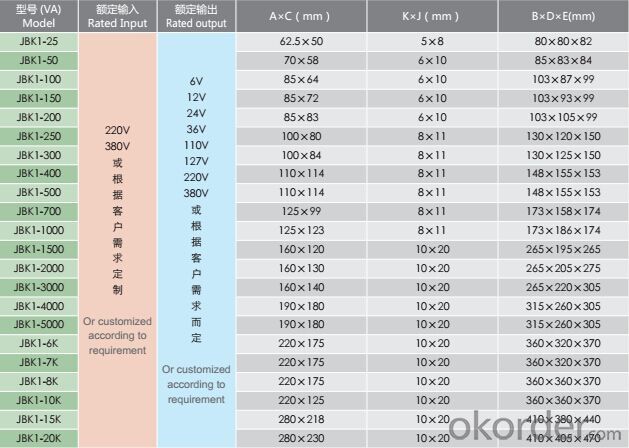

JBK1 series transformer is applicable to AC 50~60HZ circuit,rated output voltage no more than 1140V,and rated input voltage no more than 1140V,which could be widely used in the control power supply of machine tools,mechanical equipments,local lighting ,signal lamps and others.

JBK1 series transformer is applicable to AC 50~60HZ circuit,rated output voltage no more than 1140V,and rated input voltage no more than 1140V,which could be widely used in the control power supply of machine tools,mechanical equipments,local lighting ,signal lamps and others.

It has characteristics of excellent performance,reliable operation,low energy consumption,small volume,safe wiring and wide application,and as it can work for a long term under rated load ,it is an ideal variable voltage power supply.

It has characteristics of excellent performance,reliable operation,low energy consumption,small volume,safe wiring and wide application,and as it can work for a long term under rated load ,it is an ideal variable voltage power supply.

We were established in November of 1994.Until now,It has been developed to be a professional transformer manufacturer after 20 years' development,who integrates R&D,producing and marketing,Meanwhile,Xinping is the earliest transformer manufacturer which gets CQC certificate in China.

The main products of Xinping include different kinds of transformers,such as EI transformer,encapsulated transformer,switch power supply transformer,inductance transformer,BK&JBK transformer,toroidal transformer,intelligent servo transformer,three-phase dry type transformer,QZB transformer,special transformer and others.

It is located in Dezhou,Shandong Province which is the domestic key traffic hub in China,(In 2015,Dehou has been regarded as the cooperation development city with Beijing,Tianjin and Hebei).Now there are more than 400 employees in the company,15% employees are special technicians.We covers an area of about 53,000 square meter,and the floor area is more than 30000 square meter.

Xinping does a lot of tests during design,developing and the application of raw material and uses high quality raw material finally.So the transformer has the advantages of low no-load loss,high efficiency and low temperature rise.It has been widely used in househole appliances,intelligent meters,solar meters,automatic equipment,special equipment and others.

In the process of manufacturing and business,We always sticks to the principle of honoring contract,keeping credit,complying with business ethics and seeking the perfect quality.Being the leader of transformers and electronic components industry is the development goal of Xinping.Comparing price under the same quality and comparing quality&service under the same price is the business concept of Xinping.Devoting to your requirment,We will supply you excellent service from products concept to designing ,sample making,confirmation,producing,testing and delicering.Wewoule like to cooperate with you and build a bright future together.

- Q:can i use 12VAC 60w transformer for 12VAC 30w (3 10W) light?

- Yes. 60 watts is the MAXIMUM you can use with that transformer.

- Q:i m studying about the non linearity in systems and transformer is non linear in nature

- drop the voltage to the rated value otherwise it will be burnt.

- Q:e in the past with followings already??? I'm just curious I mean Transformers is at 700 mill where everything else is in the 300 mill range which isn't a bad thing but I'm just wonderin'thanksand please give like 5 or more sentences, not a because it rocks

- Because most boys/men like toys and things that blow up, plus throw in a barely dressed skank and there you have it!

- Q:hi , i got some electronics frm asia( like camera and hair dryer) , which can only be used in 220 volts. which converter or transformer sud i use which changes 110 volt to 220 volt ? and where can i get it ? i searched for it . but i found converters that change 220 v to 110 volt :(

- Do okorder

- Q:When the transformer voltage is a rated voltage, the secondary voltage in the end is how to change with the load, what is the basis for the theory of the way you ask you about the inrush

- 2 excitation current characteristics When closing the circuit breaker to charge the transformer, sometimes you can see the transformer ammeter pointer put great, and then quickly return to the normal no-load current value, the impact current is usually called the inrush current, features are as follows: 1) The inrush current contains high-order harmonic components (mainly secondary and tertiary harmonics), so the variation of the inrush current is a steep wave. 2) The attenuation constant of the inrush current is related to the saturation of the core. The deeper the saturation, the smaller the reactance and the faster the attenuation. Therefore, at the beginning of the moment decay quickly, then gradually slow down, after 0.5 ~ 1s after its value does not exceed (0.25 ~ 0.5) In. 3) Under normal circumstances, the greater the capacity of the transformer, the longer the duration of attenuation, but the general trend is the inrush current decay rate is often slower than the short-circuit current attenuation. 4) The value of the inrush current is very large, the maximum rated current of 8 to 10 times. When setting up a circuit breaker to control a transformer, the quick break can be set according to the transformer excitation current.

- Q:i want what does a transformer exactly do and not how it works

- A okorder

- Q:Is the transformer a power supply?

- Here, are relatively speaking. 1, if your equipment behind the transformer, then the output of the transformer is your power. 2, if your equipment in front of the transformer (such as a substation or generator), then the transformer is your load. 3, for example: at home, the adapter (to the phone with a transformer device), it is for your phone, that is, power, you said the socket, it is the load. 4, but if it is necessary to define it as what equipment, then it does not belong to the power supply equipment (power supply with a large generator, a small dry battery). It is able to change the power supply mode of the device.

- Q:I need to find out.I am a huge Transformers fan.

- i've watched transformes. loved both the movies.

- Q:I am very dissapointed because i lovvvve transformers but how can the movie go on without her? I know i know. the show must go on. but cmon. i hope they pull it off., does anybody know why megan fox isn't going to be in it.

- Because she said the director wanted to be Hitler, and a bunch of other mean things about him in interviews. Three men who worked as crewmen wrote a huge letter about how horrible it was working with her, and how spoiled rotten she is. The director apologized, and despite the comparison to Hitler, he stated he was still hoping she'd be in the third one. But, she once again went into an interview complaining about how hard he was to work with, so he cut her from the movie. So, basically, it's her own fault. Plus, she can't act, so it's not really going to be that much of a loss. I just hope he can pull it off considering one of the main points to the second one was Sam telling her he loved her.

- Q:Anyone know the name of this shoe like transformer.

- There are four shoe transformers. I am assuming you are talking about the ones that look like Nike Free 7.0 Running shoes made by Takara and available in Japan. There is Convoy ( Red White and Blue), Megatron (Black and Grey), Starscream ( Maroon and Black), and Marine Convoy ( White, Blue). These are exclusive to japan. However since there is no picture, I can also assume you may have a Kids meal shoe Transformer from Subway. Good luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JBK1 transformer high voltage transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords