Japanese Standard SS400 H beam with High Quality 482mm-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

| Size(mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 482*300*11.0 | 111 | 596*199*10.0 | 92.5 |

| 488*300*11.0 | 125 | 600*200*11.0 | 103 |

Packaging & Delivery of Japanese Standard SS400 H beam with High Quality 482mm-600mm for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel.

Usage of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

(1). for the plant, high-rise building construction

(2). for the bridge, shipment building

(3).for lifting and transportation machinery, equipment manufacturing base building

(4). for the support, foundation pile manufacturing

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months from the beginning of production.

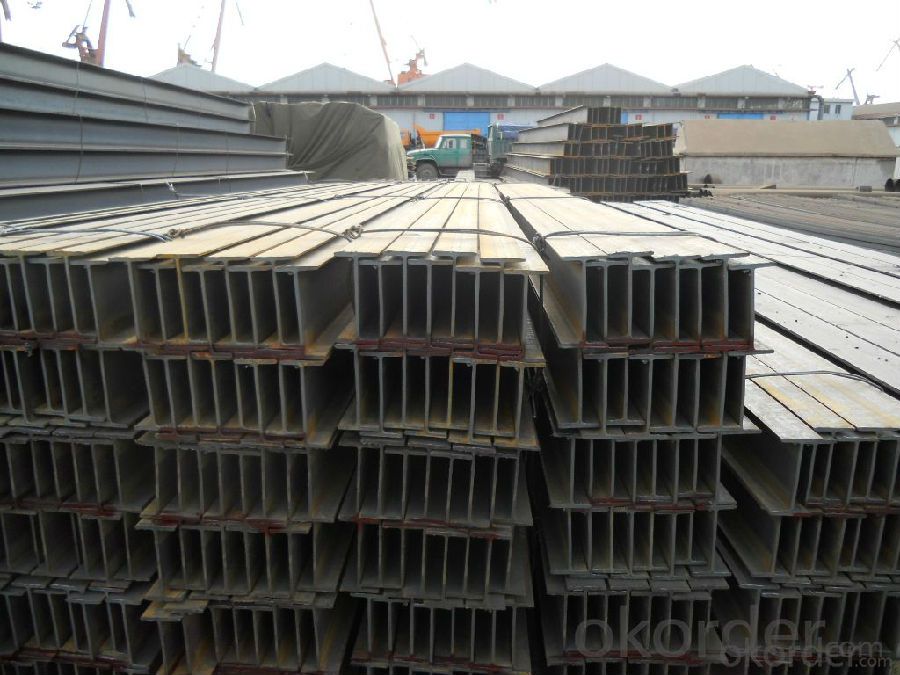

Images of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q:Can steel H-beams be used for residential construction?

- Yes, steel H-beams can be used for residential construction. They are commonly used in the construction of residential buildings and provide structural strength and stability. Steel H-beams offer several advantages such as durability, versatility, and the ability to support heavy loads, making them suitable for various residential construction applications.

- Q:Can Steel H-Beams be used in museum or gallery construction?

- Yes, Steel H-Beams can be used in museum or gallery construction. Steel H-Beams are commonly used in construction due to their strength and durability. They provide structural support and can be used to create large open spaces, allowing for versatile and flexible designs. Additionally, they can be easily fabricated and installed, making them suitable for various architectural styles and requirements.

- Q:How much is the weight of 200x200 H steel?

- What is not commonly used is the 200*204*12*12 weight of 56.7kg/ meters

- Q:How do steel H-beams contribute to the overall aesthetics of a structure?

- Steel H-beams, also known as I-beams, play a significant role in enhancing the overall aesthetics of a structure. The unique design of these beams allows for a sleek and modern appearance that can greatly contribute to the visual appeal of any building or architectural project. One way in which steel H-beams contribute to the aesthetics is through their clean and streamlined look. The straight lines and sharp edges of these beams give a sense of precision and elegance, creating a visually pleasing and contemporary aesthetic. This is especially true when these beams are left exposed or integrated into the design of the building, showcasing their structural beauty. Additionally, steel H-beams provide versatility in architectural design, allowing for greater creativity and innovation. These beams can be used to create open, spacious interiors by supporting large spans without the need for additional columns or walls. The absence of obstructions can result in a visually appealing design that promotes a sense of openness and fluidity. The use of steel H-beams also adds a touch of industrial appeal to a structure. With their strong and durable nature, these beams evoke a sense of robustness and stability. This industrial aesthetic can be particularly desirable in modern and contemporary designs, providing a contrast to other materials such as glass or wood, and adding a unique visual element to the overall composition. Furthermore, the use of steel H-beams allows for efficient use of space, contributing to a more aesthetically pleasing structure. By utilizing these beams, architects can design buildings with fewer structural elements, resulting in cleaner lines and a more minimalist appearance. This streamlined approach can create a harmonious and balanced visual effect, enhancing the overall aesthetics of the structure. In conclusion, steel H-beams contribute to the overall aesthetics of a structure through their clean and modern appearance, versatility in design, industrial appeal, and efficient use of space. By incorporating these beams into the architectural design, buildings can achieve a visually pleasing and aesthetically appealing look, enhancing the overall impact and attractiveness of the structure.

- Q:Can steel H-beams be used in underground parking structures?

- Yes, steel H-beams can be used in underground parking structures. Steel H-beams are commonly used in construction due to their strength and durability. They are capable of supporting heavy loads and can withstand the pressure exerted by the weight of the structure above. In underground parking structures where space is limited, steel H-beams are a popular choice as they provide a high strength-to-weight ratio, allowing for efficient use of space. Additionally, steel H-beams can be easily fabricated and installed, making them a practical and cost-effective solution for underground parking structures.

- Q:How do steel H-beams perform in extreme temperatures?

- Steel H-beams perform well in extreme temperatures due to their high thermal conductivity and low thermal expansion coefficient. This means that they can effectively dissipate heat and resist deformation caused by thermal expansion and contraction. Additionally, steel has a high melting point, making it suitable for use in extreme temperature conditions. However, it is important to note that prolonged exposure to extremely high temperatures can eventually weaken the steel, causing it to lose some of its structural integrity. Therefore, it is crucial to consider the specific temperature range and duration when evaluating the performance of steel H-beams in extreme temperatures.

- Q:Can steel H-beams be used for solar panel supports?

- Yes, steel H-beams can be used for solar panel supports. H-beams, also known as I-beams or universal beams, are commonly used in construction due to their strength and durability. They provide excellent structural support and can withstand the weight and wind loads associated with solar panel installations. Steel H-beams also have the advantage of being resistant to corrosion, making them suitable for outdoor applications such as solar panel supports. Additionally, their versatility allows for easy installation and adjustment to accommodate different solar panel sizes and angles. Therefore, steel H-beams are a reliable and widely used choice for supporting solar panels.

- Q:Can steel H-beams be customized based on specific project requirements?

- Yes, steel H-beams can be customized based on specific project requirements. They can be manufactured in different sizes, lengths, and thicknesses to meet the structural demands of a particular project. Additionally, they can be fabricated with specific coatings, finishes, or additional features as needed. Customization allows for the optimal design and functionality in various construction applications.

- Q:What are the different welding methods for steel H-beams?

- Steel H-beams can be welded using various methods. Some of these methods include: - Shielded Metal Arc Welding (SMAW): Also referred to as stick welding, SMAW is a widely-used method for welding H-beams. It involves using a consumable electrode coated in flux, which creates a protective shield around the weld pool to prevent contamination and oxidation. SMAW is versatile, suitable for different positions and environments. - Gas Metal Arc Welding (GMAW): Commonly known as MIG welding, GMAW employs a continuous solid wire electrode and shielding gas. This method offers fast deposition rates, produces high-quality welds, and can be easily automated. Fabrication shops often utilize GMAW for H-beam welding. - Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW utilizes a tubular electrode filled with flux instead of a solid wire. The flux provides shielding and contains deoxidizers and other additives to enhance weld quality. FCAW is known for its high deposition rates and can be used indoors or outdoors. - Submerged Arc Welding (SAW): SAW is a highly efficient method involving a continuous wire electrode fed into the weld joint while a granular flux is poured over it. The flux covers the weld, preventing contamination from the atmosphere. SAW is commonly employed in heavy-duty applications, such as welding large steel H-beams. - Laser Beam Welding (LBW): LBW is a precise and high-energy welding method that uses a focused laser beam to create a weld. It is commonly used for thin steel H-beams, offering excellent control and minimal distortion. However, LBW requires specialized equipment and is typically employed in industrial settings. These are just a few of the numerous welding methods available for steel H-beams. The selection of a specific method depends on factors such as material thickness, desired weld quality, production speed, and available equipment. It is crucial to choose the appropriate welding method based on the specific requirements of the H-beam project.

- Q:How do steel H-beams compare to aluminum beams in terms of strength and weight?

- Steel H-beams are typically stronger than aluminum beams in terms of both strength and weight. Steel is a much denser material than aluminum, meaning that steel beams can withstand higher loads and have a higher tensile strength compared to aluminum beams of the same size. This makes steel H-beams the preferred choice in structural applications that require high strength and durability. Although aluminum beams are lighter in weight compared to steel beams, they are generally not as strong. However, the lower weight of aluminum beams can be advantageous in certain applications where weight reduction is a priority, such as in the aerospace industry or for portable structures. Aluminum beams are also more resistant to corrosion, which makes them suitable for environments with high moisture or salt exposure. In summary, steel H-beams are stronger than aluminum beams, but aluminum beams are lighter and more corrosion-resistant. The choice between the two materials depends on the specific requirements of the project, including the desired strength, weight, and environmental factors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Japanese Standard SS400 H beam with High Quality 482mm-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords