Japanese Standard SS400 H beam with High Quality 340mm-396mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications of Japanese Standard SS400 H beam with High Quality 340mm-396mm:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of Japanese Standard SS400 H beam with High Quality 340mm-396mm:

| Size(mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 340*250*9.0 | 78.1 | 350*350*12.0 | 135 |

| 344*348*10.0 | 113 | 396*199*7.0 | 56.1 |

Packaging & Delivery of Japanese Standard SS400 H beam with High Quality 340mm-396mm for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months from the beginning of production.

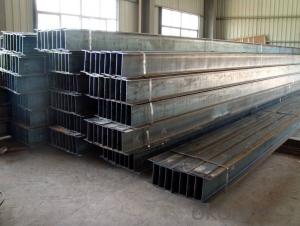

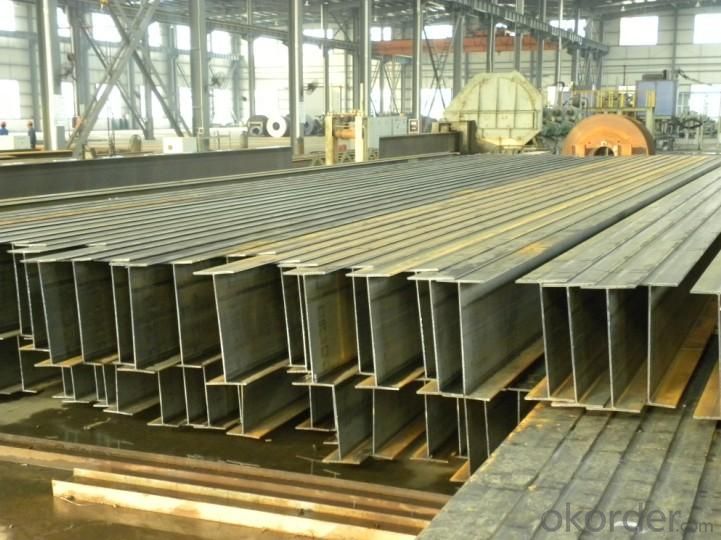

Images of Japanese Standard SS400 H beam with High Quality 340mm-396mm:

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention

- Q:What are the different anti-corrosion treatments available for steel H-beams?

- Steel H-beams have multiple options for anti-corrosion treatments. These treatments aim to safeguard the beams from corrosion caused by moisture, chemicals, or other corrosive elements. One commonly utilized treatment is hot-dip galvanizing. This method involves immersing the H-beams in molten zinc, which creates a protective zinc coating on the steel's surface. This coating acts as a barrier, preventing corrosion from reaching the steel. Hot-dip galvanizing is a highly effective and long-lasting treatment for corrosion protection. Another option is applying corrosion-resistant paint or coating to the H-beams. These specialized paints or coatings form a protective barrier against corrosion. They can be applied through various methods, such as spray painting or powder coating. This treatment is often combined with other methods, like hot-dip galvanizing, to enhance protection. Apart from galvanizing and painting, there are other anti-corrosion treatments available for steel H-beams. One of these is the use of corrosion inhibitors. Corrosion inhibitors are chemicals that form a protective film when applied to the steel's surface, inhibiting corrosion. These inhibitors can be in liquid, spray, or coating form. Additionally, electroplating is another treatment option for steel H-beams. This process involves submerging the beams in an electrolyte solution and using electricity to deposit a layer of metal, such as zinc or chromium, onto the steel's surface. This metal layer acts as a sacrificial coating, safeguarding the underlying steel from corrosion. In conclusion, various anti-corrosion treatments are available for steel H-beams, including hot-dip galvanizing, painting or coating, corrosion inhibitors, and electroplating. The choice of treatment depends on factors such as the environment the beams will be exposed to, desired corrosion protection level, and cost considerations. Consulting with professionals in the field is crucial to determine the most suitable treatment option for specific applications.

- Q:Are Steel H-Beams resistant to pests or insects?

- Yes, steel H-beams are highly resistant to pests or insects. Unlike wooden beams, steel does not provide a food source or habitat for pests, making it an effective deterrent against any potential infestations.

- Q:Use H section steel to make the beam, the span of 8 meters, the floor slab, what's the minimum H steel? What's the model?

- Choose H250X100X4X6, and if there is no snow in the south, the web can be used. 220 is the ultimate limit

- Q:Can steel H-beams be used in temporary supports during construction?

- Yes, steel H-beams can be used in temporary supports during construction. Steel H-beams are commonly used in construction due to their strength and load-bearing capabilities, making them suitable for temporary support structures.

- Q:What are the weight capacities of steel H-beams?

- The weight capacities of steel H-beams can vary depending on their dimensions and specific design. It is important to consult engineering specifications or manufacturers' data sheets for accurate weight capacity information.

- Q:Are there any limitations on the length of steel H-beams?

- The length of steel H-beams is subject to limitations. Typically, manufacturing capabilities and transportation logistics dictate the length of H-beams. When it comes to manufacturing, the size and weight of the H-beam can impact the maximum length that can be produced. Specialized manufacturing equipment and processes may be necessary for larger and longer H-beams, which may not always be readily available. Transportation logistics also contribute to the length limitation. H-beams are typically transported by truck or rail, and there are restrictions on the maximum length that can be transported without obtaining special permits. Local regulations and transportation authorities enforce these restrictions to ensure safe and efficient transportation. Moreover, longer H-beams are more susceptible to bending or warping during handling and installation, which can compromise their structural integrity. Therefore, practical limitations on the length of steel H-beams exist considering these factors. To ensure safety, efficiency, and compliance with regulations, architects, engineers, and manufacturers must carefully assess project requirements and limitations when determining the appropriate length of steel H-beams.

- Q:What are the different types of welding used for steel H-beams?

- There are several different types of welding used for steel H-beams, depending on the specific requirements and applications. The most commonly used welding techniques for steel H-beams include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW uses a consumable electrode covered in a flux to create an electric arc between the electrode and the base metal. This type of welding is versatile and widely used for various steel applications, including H-beams. 2. Gas Metal Arc Welding (GMAW): Also referred to as MIG (Metal Inert Gas) welding, GMAW uses a continuously fed wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. It provides a high deposition rate and excellent control over the welding process, making it suitable for H-beam fabrication. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a tubular wire electrode filled with flux to shield the weld pool from impurities. It is often preferred for its high welding speed and ability to handle thicker steel plates, making it suitable for heavy-duty applications involving H-beams. 4. Submerged Arc Welding (SAW): SAW involves the formation of an arc between a continuously fed bare electrode and the base metal. The weld area is shielded by a granular flux layer, which submerges the arc and prevents atmospheric contamination. Due to its high deposition rate and deep penetration capabilities, SAW is commonly used for fabricating large and thick H-beams. 5. Laser Beam Welding (LBW): LBW utilizes a high-energy laser beam to melt and fuse the base metal. This precise and controlled welding method is often used for thinner H-beams or when intricate welding patterns and minimal heat-affected zones are required. It's important to note that the specific welding technique used for steel H-beams depends on various factors, including the beam's thickness, type of steel, intended application, and required welding speed and quality. Consulting a welding professional or referring to industry standards and guidelines is recommended to determine the most suitable welding method for a particular H-beam project.

- Q:Are steel H-beams compatible with other construction materials?

- Yes, steel H-beams are compatible with other construction materials. Steel H-beams are commonly used in construction due to their high strength-to-weight ratio, durability, and versatility. They can be easily integrated with various materials such as concrete, wood, and other metals. For instance, steel H-beams can be used as structural support in combination with concrete slabs or wooden beams to create a strong and stable framework for buildings or bridges. Additionally, they can be welded or bolted together with other steel components to form complex structures. Overall, steel H-beams are highly compatible with other construction materials and can be effectively utilized in a wide range of construction projects.

- Q:How do Steel H-Beams compare in terms of lifespan and durability?

- Steel H-Beams are known for their exceptional lifespan and durability. These structural members are specifically designed to withstand heavy loads and provide long-lasting support for various construction projects. The lifespan of steel H-Beams can be significantly longer compared to other building materials such as wood or concrete. One of the key factors contributing to their durability is the inherent strength of steel. H-Beams are made from high-quality steel, which has superior tensile strength and resistance to bending and twisting forces. This enables them to withstand extreme weather conditions, seismic activity, and other external factors that can cause damage to structures over time. Moreover, steel H-Beams are not susceptible to rot, decay, or insect infestations like wooden beams. They also do not degrade or weaken under moisture, which is a common issue with concrete structures. This makes steel H-Beams highly durable and reliable, ensuring their long-term performance and structural integrity. Additionally, steel H-Beams are resistant to fire, which further enhances their lifespan and durability. Steel has a high melting point and does not contribute fuel to a fire, making it a safer choice for structural elements. This characteristic is particularly important in high-rise buildings or structures where fire protection is a critical consideration. Furthermore, steel H-Beams can be easily inspected for any signs of wear or damage. Regular maintenance and inspections can help identify and address any issues promptly, ensuring the continued durability and longevity of these structural members. In conclusion, steel H-Beams have a remarkable lifespan and durability due to their high strength, resistance to environmental factors, and fire resistance. These qualities make them an excellent choice for a wide range of construction projects where longevity and structural integrity are paramount.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Japanese Standard SS400 H beam with High Quality 340mm-396mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords