ITO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

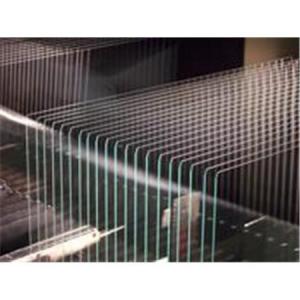

ITO Glass is manufactured through coating ITO transparent conductive layer on single side or double sides of glass according to the advanced technology of vacuum magnetron sputtering. It is the critical material for producing resistive or capacitive touch screens. When used on LCD, a SiO2 layer should be added before coating ITO layer on glass to prevent the ions of glass substrate from penetrating into the conductive layer. If it is requested for higher transmittance, one or multiple AR (anti-reflective) layers can be added before coating ITO layer on glass, thus making it the high-transmittance ITO conductive glass.

Features:

Resistance Uniformity:≤±0.1

Film Thickness Uniformity:≤±0.1

Good adhesive force

Good etching property

Good resistance to acid and alkali

Performance Parameters:

Specifications:

Thickness: 2.0mm; 1.1mm; 0.7mm; 0.55mm; 0.4mm; 0.3mm; etc. (with ±0.05mm tolerance)

Size: 14*14"; 14*16"; 20*24";

355.6*406.4mm; 370*470mm; 400*500mm,450*550mm;550*650mm; etc.

Resistance:

High (150-500Ω) used for ESD protection, Touch Screen control;

Average (60-150Ω) used for TN-LCD, electronic anti-interference;

Low (<60Ω) used for STN-LCD, transparent circuit board, etc.

Applications:

ITO Glass, as a kind of TCO glass, is mainly used to produce display screen, touch screen, mobile phone panel, home appliance panel and others.

ITO Glass used for TN-LCD/HTN-LCD/STN-LCD/TFT-LCD/PDP/OLED/VFD/LCOS in the application of vehicle, consumer electronics, industrial products, LCD (liquid crystal display):

surface resistance: 3.5-100Ω

thickness: 0.4-1.1mm

ITO Glass used for touch screen in the application of mobile phone, displayer, GPS, PDA, instruments and apparatuses, etc.

surface resistance: 150-600Ω

thickness: 0.4-3.0mm

- Q:What materials are needed for the production of glass bottles and what are their proportions?

- There are many kinds of glass, different kinds, different uses, and different ingredients.

- Q:Comparison of plexiglass steel bridge and inorganic glass steel bridge

- 4, can release harmful gases, human health and environmental protection have a certain impact. 5, high cost, but also a larger fluctuation of raw material prices. 6, after the waste is not easy to handle. Two, inorganic glass fiber reinforced plastics (referred to as Magnesium Oxide) advantages: 1, high temperature. (under normal circumstances, Fahrenheit temperature of 400 degrees Celsius, to maintain the product is not deformed), 2, anti-aging, 20 years without deformation of the product. 3. Purify the air and absorb carbon dioxide from the air. 4, high strength. 5, waterproof performance is good. 6, light weight, only in plexiglass.

- Q:What are the raw materials made of glass and plastics?

- Low density polyethylene, referred to as LDPE is the amount of varieties of plastic packaging and printing industry in most countries. The proportion is 0.92 ~ 0.93, can float in water. Low crystallinity (60%), under the pressure of 1000 ~ 3000kg/C square meters of bulk polymerization of high pressure polyethylene. At 23 degrees Celsius, the density of rolling around 0.92. The molding is poor, for blow molding processing into tubular film. It is suitable for food packaging, packaging, cosmetics packaging fiber products.

- Q:What are the anticorrosive materials for glass fiber reinforced plastic?

- Dead work:Before the construction, make sure that the cement ground is completely dry and the foundation is smooth, and then the bottom oil brushing work can be done.Preparation of glass fiber reinforced plastic raw materials and construction equipment.

- Q:What material is the simulation tree made of?

- The earliest to do simulation trees, rockery are used cement, the recent simulation tree and rockery, with a lot of resin. First, the resin simulation degree is extremely high, two is the cost and the cement cost approximately.

- Q:What is the ratio of raw materials for glass mildew proof powder?

- Features: using high-quality coconut shell as raw materials, by crushing, mixing, extrusion, drying, modification and so on;R & D institutions: Department of chemical and chemical engineering of Nanjing University, GREE R & D institutions, Department of environmental science, Nanjing University, Jiangsu physical and chemical testing center;Advanced: for the domestic initiative, greatly solved the domestic construction materials, such as glass mildew problems, environmental protection is good, in line with Europe and the United States and other countries

- Q:How is glass made? I heard that sand is used, but what is the concrete principle?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q:What are the materials for car windshields? Is there anything different than ordinary glass?

- At present, the front windshield of the car is mainly made of laminated glass and sandwich area toughened glass, and it can bear strong impact force.

- Q:FRP process piping manufacturing process?

- A, lined with resin preparation. According to the quality control department according to the work environment, temperature conditions made resin formula system for lining resin matching, batching quantity according to the manufacturing schedule reasonable grasp. When the situation changes, the quality inspection department and the manufacturing department shall adjust the formulation in time, and prepare the resin according to the new formula;B, material preparation. According to the design requirements, the material needed for making the lining is transported to the designated position, and some wide width reinforcement materials are firstly cut and processed to the design width;C, lining production. According to the design requirements of the paving layer step liners, each layer in the process of laying under reasonable tension between the amount of overlap, and combined pressure roller rolling repeatedly from bubble to ensure fiber soaked completely. And requests each enhancement material layer to achieve the design resin content request;D, preliminary self check. According to the design requirements of overlay end of each layer, the operation requirements for quality testing of workers: whether the design meets the lining thickness, whether there is a local poor glue, hanging glue phenomenon, whether there is a white spot, whether there is a bubble, etc., if the occurrence of the above situation timely report and take measures;

- Q:What are the production processes and raw materials of float glass?

- Float glass production process refers to the glass liquid in molten metal floating on the surface of the flat glass production process. The production process of float glass is to select the raw material needed for the production of glass according to the designed glass composition, and weigh various raw materials according to the designed material, and then prepare the mixture by mixing.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 1984 |

| Annual Output Value | US$ 0.5 Million |

| Main Markets | Mid East; Eastern Europe; North America; Europe; Asia |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese; Korean |

| b)Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ITO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords