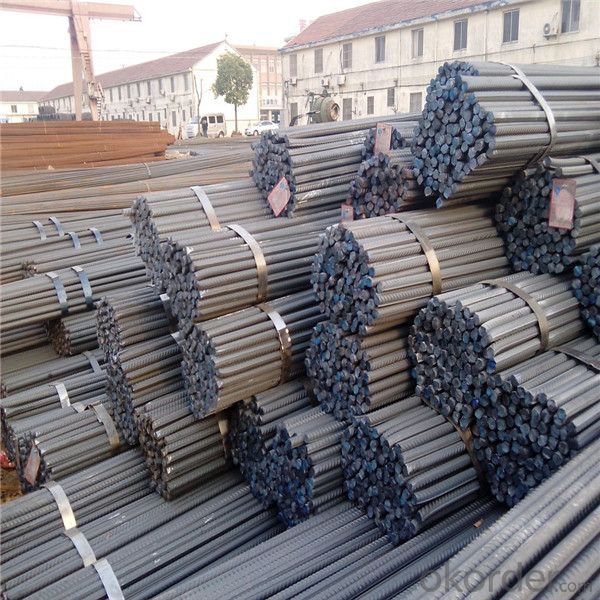

Iron rods of 6-25MM HRB400 HRB500 for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Deformed Steel bar is a common steel reinforcing bar, used in reinforced concrete and reinforced masonry structures.

It is formed from mild steel, and is given ribs for better frictional adhesion to the concrete. The Deformed Steel bar is an

iron rod , a weldable plain reinforcing steel bar, and can be used as well for steel meshes.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered

with special plastic "mushroom" caps.

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:Are steel rebars suitable for use in seismic zones?

- Yes, steel rebars are suitable for use in seismic zones. They are commonly used in construction to enhance the strength and durability of concrete structures, making them more resistant to seismic forces. The added reinforcement provided by steel rebars helps prevent concrete from cracking or collapsing during an earthquake, ensuring the safety and stability of the building.

- Q:What are the different types of steel rebars used in tunneling?

- There are typically two types of steel rebars used in tunneling: epoxy-coated rebars and stainless steel rebars. Epoxy-coated rebars are commonly used in tunneling projects to provide corrosion resistance and enhance durability. On the other hand, stainless steel rebars are used in situations where higher corrosion resistance is required, such as in highly acidic or alkaline environments.

- Q:Can steel rebars be used in modular bridges?

- Yes, steel rebars can be used in modular bridges. Steel rebars are commonly used as reinforcement in concrete structures, including bridges. In modular bridges, where pre-fabricated components are assembled on-site, steel rebars can be used to strengthen the concrete elements and provide additional support for the structure. The rebars are embedded within the concrete elements to enhance their tensile strength and prevent cracking or collapsing under heavy loads. This reinforcement ensures the durability and stability of the modular bridge, making it a reliable and safe transportation solution.

- Q:What are the different types of steel rebars used in industrial warehouses?

- There are several types of steel rebars commonly used in industrial warehouses, including carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. Each type has its own specific properties and benefits, catering to different requirements and environments within the warehouse.

- Q:Can steel rebars be used in industrial structures?

- Yes, steel rebars can be used in industrial structures. Steel rebars provide additional strength and reinforcement to concrete structures, making them suitable for use in various industrial applications such as factories, warehouses, power plants, and other heavy-duty structures.

- Q:How do steel rebars affect the flexural strength of reinforced concrete elements?

- The flexural strength of reinforced concrete elements is greatly influenced by steel rebars. Rebars improve the ability of concrete elements to withstand bending or flexural forces. To provide tensile strength, high-strength steel rebars are embedded within the concrete. Concrete is strong when compressed but weak when subjected to tension. By incorporating rebars, the resulting composite material benefits from the concrete's high compressive strength and the steel's excellent tensile strength. When a flexural load is applied to a reinforced concrete element, such as a beam or slab, the rebars distribute the load across the section. This effectively resists the concrete's tendency to crack and fail under tension. Acting as reinforcements, the rebars resist the tensile forces that occur due to bending, thus increasing the structure's flexural strength. The flexural strength of reinforced concrete elements is greatly influenced by the size, spacing, and arrangement of the rebars. Proper design and placement of rebars ensure optimal resistance to anticipated bending forces. Factors such as the element's span, expected loads, and desired strength level must be carefully considered. In addition, the bond between the rebars and the concrete is crucial for transferring bending stresses. Sufficient concrete cover over the rebars protects them from corrosion, ensuring their durability and the integrity of the structure. Corrosion weakens the bond between steel rebars and the surrounding concrete, compromising the flexural strength of the reinforced element. In conclusion, steel rebars greatly enhance the flexural strength of reinforced concrete elements by providing necessary tensile strength to resist bending forces. Proper design, placement, and bonding of rebars are vital to ensuring the durability and structural integrity of reinforced concrete structures.

- Q:How do steel rebars affect the overall strength of concrete structures?

- Steel rebars significantly contribute to the overall strength and durability of concrete structures. They are commonly used as reinforcement in concrete to enhance its tensile strength, which is the ability to withstand pulling or stretching forces. Concrete on its own is strong in compression but weak in tension. When external forces like bending or stretching are applied to the concrete, it tends to crack and fail. This is where steel rebars play a crucial role. By adding rebars to the concrete, the tensile strength of the structure is greatly improved. The rebars act as a strong skeleton within the concrete, providing resistance against tensile forces. When the concrete is subjected to tension, the rebars take up the load and distribute it evenly, preventing cracks from forming and enhancing the overall strength of the structure. This reinforcement also helps to limit the propagation of cracks, ensuring that the structure remains intact and stable even under substantial loads or adverse conditions. Moreover, steel rebars also enhance the structural integrity of concrete structures by improving their resistance to bending, shearing, and torsional forces. They increase the stiffness and stiffness modulus of the concrete, making it more resistant to deformation and enhancing its load carrying capacity. In addition to improving the structural strength, steel rebars also play a vital role in preventing corrosion of the concrete. They are made of corrosion-resistant materials, such as stainless steel or galvanized steel, which protects the concrete from moisture and other corrosive elements. This ensures the longevity and durability of the concrete structure. In conclusion, steel rebars significantly enhance the overall strength and durability of concrete structures by improving their tensile strength, resistance to bending and shearing forces, and preventing corrosion. They provide the necessary reinforcement to make the concrete capable of withstanding external forces, ensuring the safety and longevity of the structure.

- Q:Can steel rebars be used in structures with high electromagnetic shielding requirements?

- Steel rebars can be used in structures with high electromagnetic shielding requirements to some extent. Steel is inherently a good conductor of electricity, which means it can help to divert and absorb electromagnetic waves. This property makes steel rebars helpful in reducing the penetration of electromagnetic radiation into structures. However, it is important to note that the effectiveness of steel rebars in providing electromagnetic shielding depends on various factors. The thickness and quality of the steel rebars, the design and construction of the structure, and the frequency and intensity of the electromagnetic waves all play a role in determining the level of shielding provided. In cases where extremely high electromagnetic shielding requirements are necessary, additional measures may be needed. These could include using specialized materials specifically designed for electromagnetic shielding, such as conductive coatings or composite materials with high conductivity. Moreover, it is crucial to consider the overall design and construction of the structure to ensure proper grounding of the steel rebars. Proper grounding helps to channel and dissipate the electromagnetic energy safely, preventing the buildup of potentially harmful electromagnetic fields. In conclusion, while steel rebars can contribute to electromagnetic shielding in structures, the level of shielding provided may vary depending on several factors. For structures with stringent electromagnetic shielding requirements, it is advisable to consult with experts in the field to determine the most appropriate materials and construction techniques.

- Q:What are the different types of splices used for steel rebars?

- There are several types of splices used for steel rebars, including lap splices, mechanical splices, and welded splices. Lap splices involve overlapping two rebars and securing them with tie wires or rebar clamps. Mechanical splices use couplers or threaded sleeves to connect rebars together, providing a more reliable and efficient connection. Welded splices involve welding the ends of rebars together, creating a strong and permanent connection. The choice of splice type depends on factors such as project requirements, rebar size, and construction methods.

- Q:What are the factors that can cause corrosion in steel rebars?

- The factors that can cause corrosion in steel rebars include exposure to moisture, oxygen, chloride ions from saltwater or deicing salts, carbonation of concrete, and the presence of stray electrical currents.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Iron rods of 6-25MM HRB400 HRB500 for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords