Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sizes: DN100 - DN800

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80 C

Connection: RF

Constant Head Check Valve

Sizes: 4“ - 48"

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80°C

Connection: RF

| aterial list(CN standard): | |||||

| NO. | Part Name | Carbon Steel Series | Stainless Steel Series | Alloy Steel Series | Low-temperature Steel Series |

| 1 | Body | WCB | CF8 | WC6 | LCB |

| 2 | DISC | WCB | CF8 | WC6 | LCB |

| 3 | Washer | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 |

| 4 | Bonnet | WCB | CF8 | WC6 | LCB |

| 5 | Studs | 35CrMoA | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 6 | Nut | 35# | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 7 | Spring | 60Si2Mn | 0Cr18Ni9(304) | 0Cr18Ni9(304) | 0Cr18Ni9(304) |

| Technical Specification: | |||||||

| Design Standard | GB/T 12235 | ||||||

| Temperature Pressure Rating | GB/T 12224 | ||||||

| Structural Length | Factory Standard | ||||||

| Flange Dimensions | GB/T 9113,GB/T 79 | ||||||

| Inspection and Test | JB/T 9092,GB/T 13927 | ||||||

| nominal pressure | PN1.6 | PN2.5 | PN4.0 | PN6.4 | PN10.0 | PN16.0 | |

| Test Pressure(Mpa) | Body Test | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 24.0 |

| High Pressure Seal | 1.76 | 2.75 | 4.4 | 7.04 | 11.0 | 17.6 | |

| Low Pressure Seal | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Applicable temperature | -196°C~550°C(Differeent temperature use different material) | ||||||

| Applicable Medium | water,gas,oil and corrosive media(different media use different material) | ||||||

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

| Power: | Hydraulic | Material: | Carbon Steel, Stainless Steel | Temperature of Media: | Medium Temperature |

| Media: | Water, Oil, Gas etc. | Port Size: | DN250 | Place of Origin: | Hebei, China (Mainland) |

| Model Number: | OEM | Brand Name: | cmax | Application: | General |

| Name: | Check Valve | Type: | Lift Check Valve | Nominal Diameter: | DN15~900,NPS 1/4 ~36 |

| Nominal Pressure: | PN1.0-16.0MPa,ANSI CLASS 150-900,JIS10-20K | Connection Type: | Flange, butt welding, thread, socket welding, the clamp, etc | Working Temperature: | -196℃~540℃ |

| Valve Body Material: | WCB,CF8(304),CF3(304L),CF8M(316),CF3M(316L), | Applicable Medium: | Water, Oil, Gas etc | Model: | OEM |

| Certificate: | ISO9001, ISO4001 |

Application

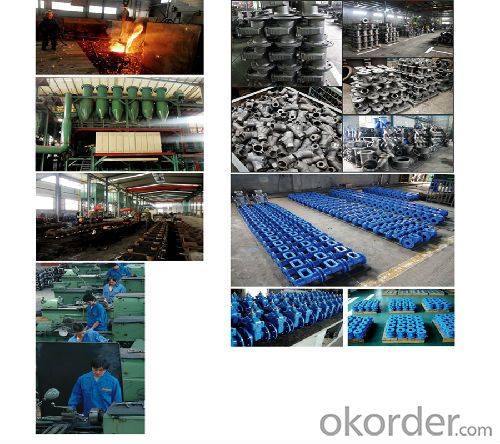

Petroleum, chemical industry, pharmacy, fertilizer, power industry etc.

Advantage

1.Lift check valve is self-sealing valve. The disc can be acted by the flow which can protect against the media flow back.

2.The disc with spring can keep the valve work in any direction.

3.Reasonable structure, reliable sealing, excellent performance and attractive appearance make a TKFM valve.

- Q:Check valve does not automatically check back, how to adjust?

- 4 the vertical lift check valve shall be mounted on a vertical pipe.5, the lift type horizontal check valve shall be installed on the horizontal pipe.6. Do not check the weight of the valve in the line. The large check valve shall be independently supported so as not to be affected by the pressure caused by the piping system.

- Q:The difference between backflow preventer and check valve

- Plain and simpleBackflow preventer is double acting, better than check valve

- Q:Is it better to have explicit rules in the relevant specifications? Thank you, ah, ah, urgent.

- Article 8.5 of the code for fire protection design of high-rise civil buildings provides as follows:8.5.3 one of the following circumstances shall be equipped with fire dampers for the ventilation and air conditioning systems:8.5.3.1 pipe through fire compartment.

- Q:How can the fast closing noise check valve prevent water hammer?

- It is recommended to see the principle of water hammer in fluid mechanics and the structure and principle of the check valve. These are not a few words to talk about, you can understand, and the important thing is to study your own! Only in this way can I really understand.

- Q:What kind of check valve is used in the sewage pump of sewage treatment plant?

- 2. installation of pump outlet check valve*Swing check valves are generally mounted on horizontal pipes: for bore DN~80mm check valves, they can also be mounted on vertical or upward sloping pipes.*Straight through lift check valves shall be installed on horizontal pipes; vertical lift check valves must be mounted on vertical pipes and medium upward flow.*As the check valve is easy to damage, therefore, should be installed near the pump outlet valve, in the upper part of the check valve with a cut-off valve (general use of ball valve or gate valve), easy to overhaul.*To facilitate the relief of the check valve before disassembly, the relief valve shall be installed between the check valve and the shut-off valve.

- Q:What are the types of check valves?

- Taiwan reasonable, this may not have domestic, if you can name, you can call three one-way valve, we can see in accordance with the structure of the spring type.Front Ze valve provides: hope to adopt!!!I hope I can help you.

- Q:What is the HH44X-16 H of the double acting slow closing check valve? Can you explain it in detail?

- 1. The first H is the meaning of the check valve (the first letter of the Chinese phonetic alphabet). The second H is the meaning of "slow closing" (the first letter of the Chinese phonetic alphabet).

- Q:Is the check valve the same?

- Same。 Call a difference; a thing. You come to our store to have a look.

- Q:What is the difference between check and check valves? Check and check valves?

- 2, gravity: and spring similar to rely on the valve's own gravity closed to prevent backflow.

- Q:Pump adapter need check valve?

- Multifunctional pump combination device usually comes with safety valves and check valves, usually in the flange pipe interface or who is interface settings simple check valve, safety valve is white, but does not apply to the north, the northern cold, need to separate the pipes below plus a check valve, a higher temperature of the South may be suitable for direct use of non frozen.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords