Insulation Tape Jacket Repair and Restoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of KC71 Tape

• KC 71 is a self-amalgamating ethylene propylene rubber (EPR) tape used on solid dielectric cable for electrical insulation and jacketing in splices up to 69Kv and for building stress cones in terminations up to 35kV.

• The tape comes with a separator that is removed during the taping process.

• Its 0,76mm thickness and quick amalgamation facilitates a rapid, void free insulation build-up that is electrically stable and moisture proof.

• KC 71 is suitable for use with conductors rated at 90°C with an emergency overload rating of 130°C.

• The tape is also resistant to corrosion, chemicals and ultra violet light.

• KC 71 fully meets the Table 1 requirements for Type III tape in ASTM D 4388.

Dimensions of KC71 Tape

1” x .030” x 16.4'

25mm(width) x 0.76mm(Thickness) x 5m(length)

Consult us for other sizes

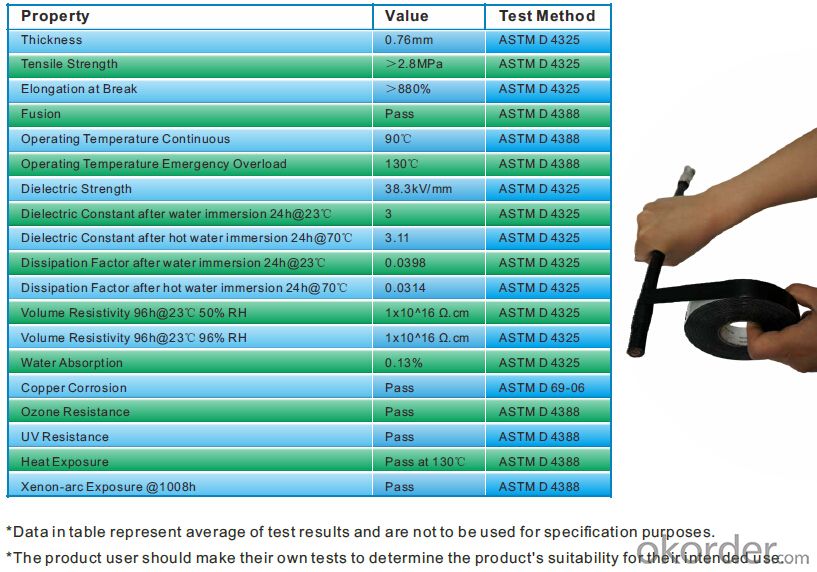

Specifications of KC71 Tape

Applications of KC71 Tape

• Electrical insulation and jacketing in splices of solid dielectric cable up to 69kV

• Building stress cones in terminations of solid dielectric cable up to 35kV

• Jacketing of indoor terminations

• Bus bar insulation and corrosion protection

• Jacket repair and restoration in all types of cable

• Moisture sealing applications

FAQ

Q1.Can we have the customized size tape?

A1:Consult us for other size

Q2:Is this Tape environmental-friendly?

A2:This tape is flame/arec resistance and environmental-friendly.

Q3:Can we have the sample/trail order to test quality?

A3:Surely we support the sample/trail order.

- Q:What materials are used for steel pipe corrosion protection?! How about the anticorrosion effect of PE tape? Or is 3PE's effect better? What's the lower cost?

- Asphalt anti-corrosion layer 2, coal tar enamel corrosion protection layer 3, epoxy coal tar anti-corrosion layer 4, 2PE 3PE anti-corrosion layer 5, fusion bonded epoxy powder corrosion protection layer 6, polyethylene tape anticorrosion layer

- Q:Does hydrochloric acid react with raw tape?

- The raw rubber tape is mainly used for the interface of hot and cold water supply pipe fittings, so as to enhance the tightness of the pipe connection, prevent the interface from leaking, and increase the leak proof function of the interface. At present, sanitary tapes are used in HVAC and water supply and drainage.

- Q:PVC does electric tape belong to rubber?

- The name is polyvinyl chloride electrical insulation tape, belonging to electrical plastic products.

- Q:Where are the PVC tape coating machines being made?

- Product characteristics:Using VVVF, single / dynamic linkage; automatic edge tension control, magnetic powder brake material; scientific design, precision coating system, ensure the material on the glue evenly; diesel combustion engine preheating fast, high heat, automatic temperature control. According to customer needs, optional electric heating tube or high temperature heat transfer oil model.

- Q:Is the transparent aluminum foil tape the same as the PVC tape?

- PVC (PVC) film is used as base material and applied to rubber pressure-sensitive adhesive to make good insulation, pressure resistance and weather resistance. Unique adhesive formula, good adhesion and touch, good adhesive force. Applicable to wire feeder, electrical insulation protection, automotive wiring and other electrical insulation protection.

- Q:What are the differences between electrical tape and electrical tape? Which ones are used in those industries?

- Electrical insulating tape, with soft polyvinyl chloride (PVC) film substrate, manufacture coated rubber pressure sensitive adhesive, with insulation, fire resistance, voltage resistance good, cold resistance, suitable for automotive wiring, wire winding, insulation protection etc..

- Q:What material is the base material of PVC electric tape?

- Specializing in the production of high temperature adhesive tape, electrical tape, color electrical tape, PVC color mark tape, PVC mark tape, PVC pipeline adhesive tape and other kinds of tape

- Q:PVC are the thickness of the electrical tape the same?

- The difference is just to distinguish the wires. Avoid accidents on the wrong line.

- Q:What specifications do you have for PVC electric tape?

- The first is the PVC of type 3. Compared with type 5, the production of type 3 PVC requires long reaction time and high polymerization temperature, and requires high added material. The production cost is 50-100 yuan / ton higher than that of type 5. 3 type PVC high purity, small fish eye, easy to blister, with high temperature resistance, insulation, soft products and other characteristics, mainly for the production of soft products, such as wire and cable, agricultural films, conveyor belts, plastic products for daily use.Again, the SG-7/SG-8 and SG-5 PVC. The three resins are basically the same process and the production unit is the same. The main difference lies in additives, formula, polymerization temperature, reaction pressure and so on.In terms of reaction temperature and reaction pressure. SG-8 resin has basically reached the limit pressure of polymerization reactor, reaction conditions more stringent requirements, the operation, safety, technology, personnel quality and other aspects of the requirements, and it is more difficult to control the quality of resin.

- Q:What is PVC double sided tape?

- [] double-sided tape is made of paper or cloth, plastic film substrate, then the elastomer pressure-sensitive adhesive or resin adhesive coating made in the substrate of the roll type adhesive tape is composed of base material, adhesive, release paper (film) or silicone oil paper is composed of three parts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulation Tape Jacket Repair and Restoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords