Insulation Tape High Temperature Electrical Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of KC71 Tape

• KC 71 is a self-amalgamating ethylene propylene rubber (EPR) tape used on solid dielectric cable for electrical insulation and jacketing in splices up to 69Kv and for building stress cones in terminations up to 35kV.

• The tape comes with a separator that is removed during the taping process.

• Its 0,76mm thickness and quick amalgamation facilitates a rapid, void free insulation build-up that is electrically stable and moisture proof.

• KC 71 is suitable for use with conductors rated at 90°C with an emergency overload rating of 130°C.

• The tape is also resistant to corrosion, chemicals and ultra violet light.

• KC 71 fully meets the Table 1 requirements for Type III tape in ASTM D 4388.

Dimensions of KC71 Tape

1” x .030” x 16.4'

25mm(width) x 0.76mm(Thickness) x 5m(length)

Consult us for other sizes

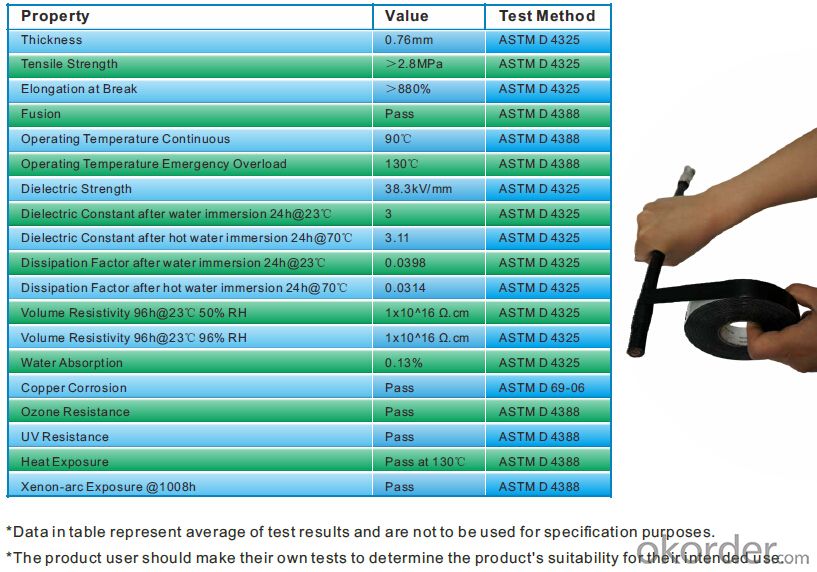

Specifications of KC71 Tape

Applications of KC71 Tape

• Electrical insulation and jacketing in splices of solid dielectric cable up to 69kV

• Building stress cones in terminations of solid dielectric cable up to 35kV

• Jacketing of indoor terminations

• Bus bar insulation and corrosion protection

• Jacket repair and restoration in all types of cable

• Moisture sealing applications

FAQ

Q1.Can we have the customized size tape?

A1:Consult us for other size

Q2:Is this Tape environmental-friendly?

A2:This tape is flame/arec resistance and environmental-friendly.

Q3:Can we have the sample/trail order to test quality?

A3:Surely we support the sample/trail order.

- Q:PVC how to distinguish between true and false electrical insulation tapes?

- It is made of rubber type pressure sensitive adhesive. It has good insulation, fire resistance, voltage resistance, cold resistance and so on. It is suitable for automobile wiring, winding, insulation protection, etc..

- Q:What are the weights for profiled steel sheet roofing, spunbond polyethylene and polypropylene waterproof and breathable?

- Polyethylene film is a commonly used plastic film, because of its non-toxic, so a lot of food used for making packaging bags. Notice the difference between PVC and polyvinyl chloride (PVC). The simple way is to make the polyethylene film for ignition, and the non flammable is PVC film.A separation layer between a polyethylene film, a barrier layer, an intervening coil, and concrete or other protective layer. It is also considered a separate protective layer.

- Q:PVC does electric tape belong to rubber?

- The name is polyvinyl chloride electrical insulation tape, belonging to electrical plastic products.

- Q:PVC pipe and duct tape tape what is the difference

- Duct duct tape:Duct tape is to heat the textile fiber cloth as the substrate. The utility model has the advantages of strong peeling force, tensile resistance, grease resistance, aging resistance, temperature resistance, water proof and corrosion prevention, so that the utility model is also used for pipe waterproof.I hope my answer will help you

- Q:What's the name of the tape?

- Second, the raw rubber tape belongs to a kind of white opaque film PTFE product, usually used as an auxiliary material in plumbing and heating installation. Its chemical name is PTFE, its product name is "PTFE" - raw tape. The raw tape is actually Teflon, and the raw meal band is only its commonly known name.

- Q:PVC tape does not contain any gum. What's the best idea?

- The permanent adhesive tape is made of lead-free environmental protection, especially the permanent warning tape. After use, no residual rubber is left. It is a good adhesive tape for protection.

- Q:What is a composite PE tape?

- Main technical specifications of adhesive tape1. Tensile strength >20MPa; patch >15MPa2, elongation at break is >200%, >300%3, peel strength >20N/cm; to coating primer steel plate >5~10N/cm; to back material >5~10N/cm4. Electrical strength >3MV/m5, water absorption rate <0. 03%Main technical specifications of primer1, table dry time 1~5min2, viscosity 10~15s

- Q:Theoretical dosage of polyethylene anticorrosion insulating tape

- Anticorrosion tape dosage = pipe surface area * (1+5%)5% is theoretical loss

- Q:What specifications do you have for PVC electric tape?

- PVC is polyvinyl chloride, it is one of the largest plastic products in the world. It is cheap and widely used. PVC resin is white or light yellow powder. It can not be used alone. It must be modified. PVC is an amorphous white powder with poor branching degree and poor stability to light and heat. Different additives can be added according to different uses, and polyvinyl chloride plastics can exhibit different physical and mechanical properties. A variety of hard, soft and transparent products can be made by adding proper amount of plasticizer in PVC resin.

- Q:What are the uses of black cloth tape

- I learned on the PVC plastic network: PVC insulation tape and PVC insulation tape is not the same kind of adhesive tape

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulation Tape High Temperature Electrical Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords