insulation FRP grating corrosion resistence high strength SGS ISO9001 certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

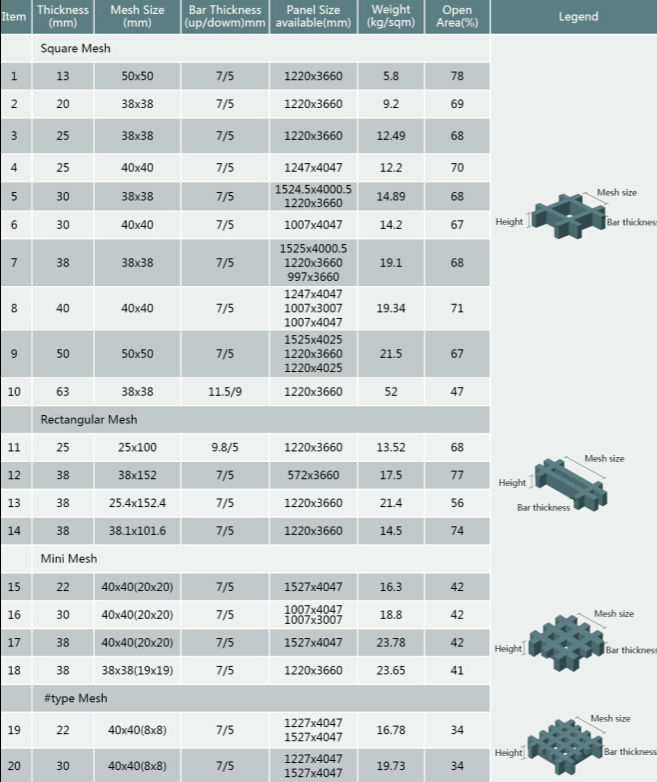

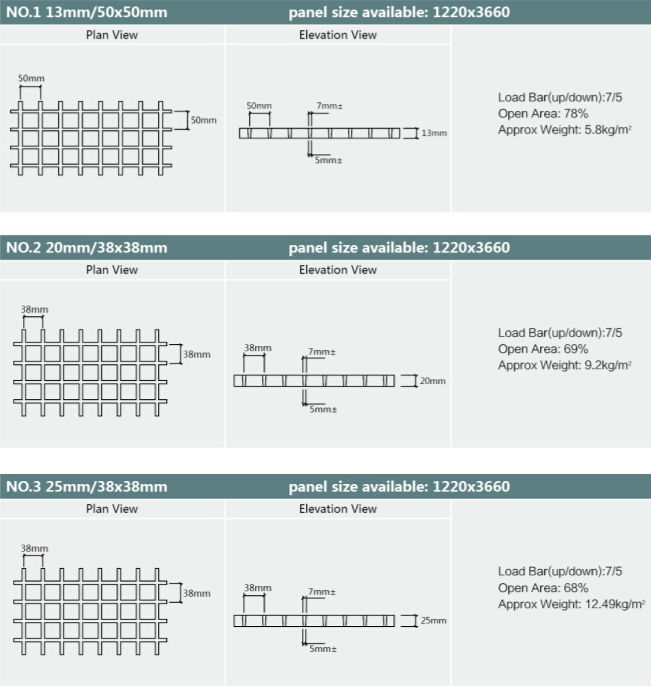

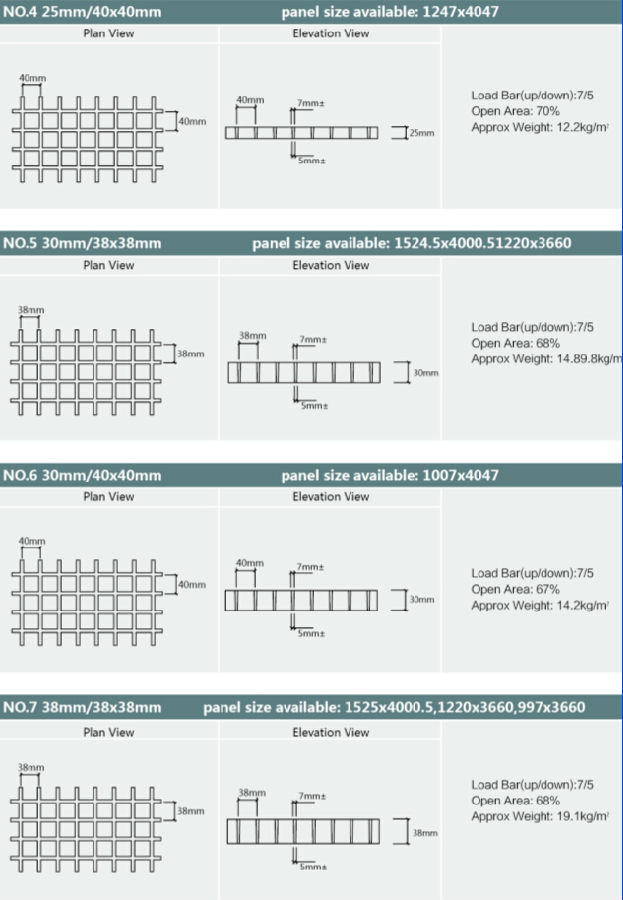

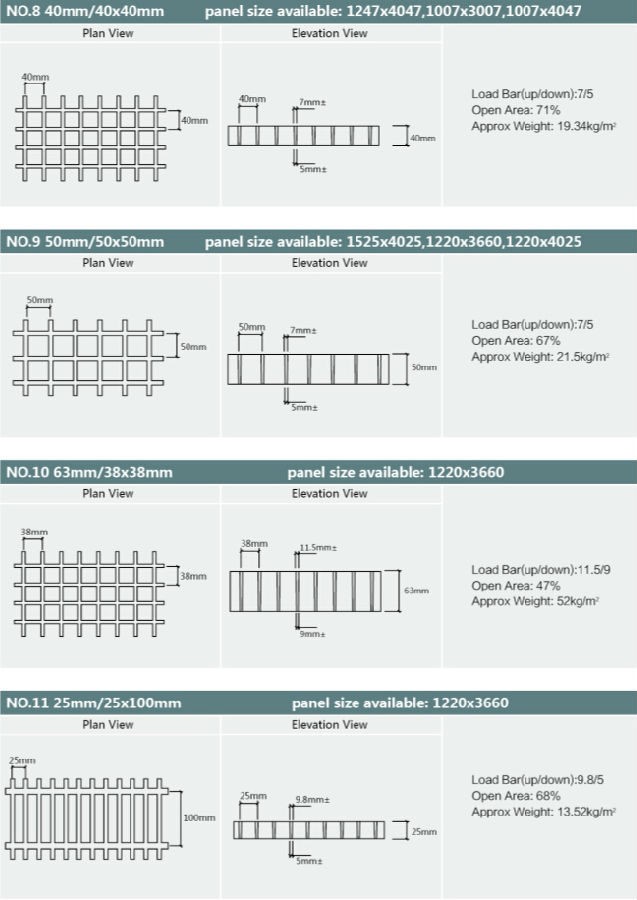

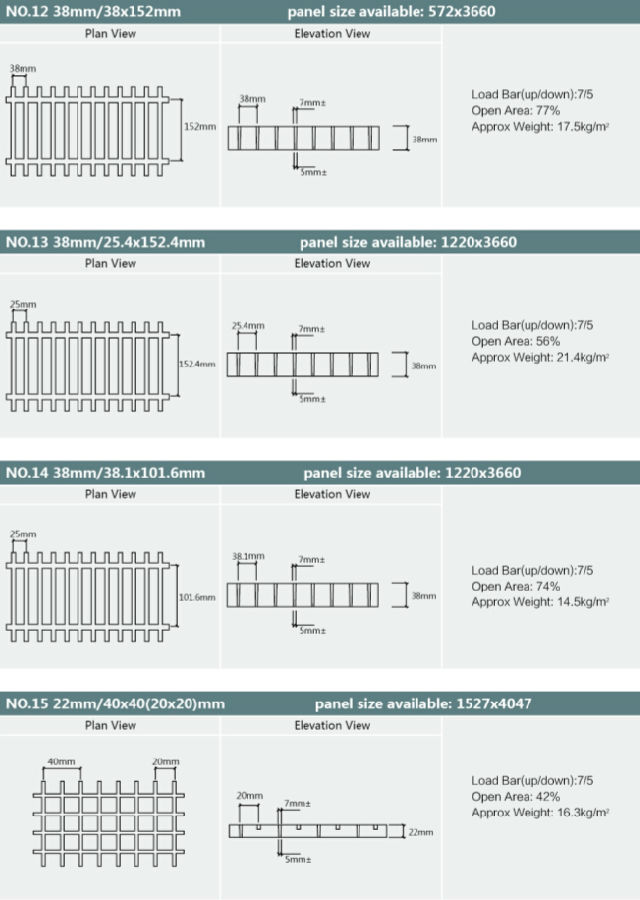

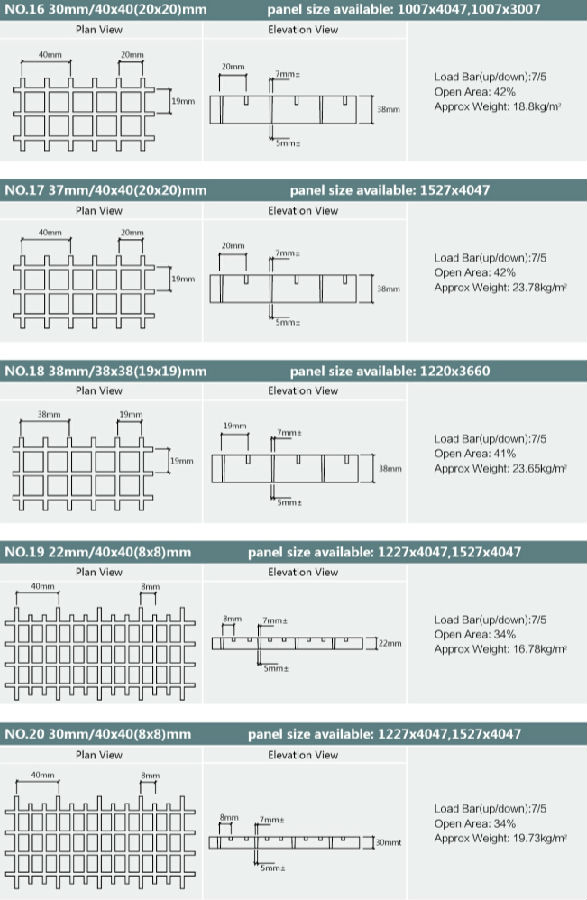

Moded Grating Sizes List:

- Q:What is the fatigue resistance of FRP pultrusion profiles?

- The fatigue resistance of FRP pultrusion profiles refers to their ability to withstand repeated or cyclic loading without experiencing failure or degradation over time. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their exceptional fatigue resistance compared to other traditional materials such as steel or aluminum. The fatigue resistance of FRP pultrusion profiles can be attributed to the nature of the composite material itself. FRP profiles are typically made by impregnating continuous fibers, such as fiberglass or carbon fiber, with a polymer resin matrix. This combination of fibers and resin creates a material that exhibits high strength-to-weight ratio, excellent corrosion resistance, and superior fatigue properties. The fiber reinforcement in FRP profiles provides them with inherent resistance against fatigue. The continuous fibers distribute and absorb stresses more evenly, preventing the formation and propagation of cracks or defects that can lead to failure. Additionally, the polymer resin matrix acts as a protective layer, shielding the embedded fibers from environmental factors that could degrade their fatigue resistance. The fatigue resistance of FRP pultrusion profiles can be further enhanced through specific design considerations and manufacturing techniques. For example, the orientation and arrangement of the fibers within the profile can be optimized to improve the load-carrying capacity and fatigue life. Additionally, the use of advanced resin systems and manufacturing processes can result in improved interfacial bonding between the fibers and the matrix, further enhancing the fatigue resistance. Overall, FRP pultrusion profiles are renowned for their exceptional fatigue resistance. This makes them an ideal choice for applications that require long-term durability and resistance to cyclic loading, such as infrastructure components, aerospace structures, marine applications, and sporting goods.

- Q:How do FRP pultrusion profiles handle compression loads?

- The unique and effective handling of compression loads by FRP pultrusion profiles is attributed to their structure and material composition. By pulling continuous fibers, such as glass or carbon, through a resin bath and a heated die, the profiles are formed and cured. In terms of compression loads, FRP pultrusion profiles demonstrate exceptional performance. The incorporation of continuous fibers within the resin matrix results in highly rigid and strong profiles, enabling them to effectively withstand compressive forces. The fibers evenly distribute the load along the profile's length, preventing localized failure and ensuring overall structural integrity. Furthermore, the fiber reinforcement in FRP pultrusion profiles provides excellent resistance against buckling. Buckling occurs when excessive compressive loads cause instability and failure in slender structural members. The robust strength-to-weight ratio of the fibers helps prevent buckling, allowing the profiles to endure significant compression forces without compromising their structural integrity. Moreover, the resin matrix in FRP pultrusion profiles plays a vital role in handling compression loads. It acts as a protective layer, safeguarding the fibers from damage or fractures caused by compressive forces. Additionally, the resin serves as a medium for load transfer, effectively distributing the compressive load to the fibers, which then carry it throughout the entire profile. In summary, FRP pultrusion profiles are exceptionally well-suited for managing compression loads due to their fiber reinforcement and resin matrix. They offer remarkable strength, stiffness, and resistance to buckling, making them an ideal choice for various applications where compression loads are a concern.

- Q:Can FRP pultrusion profiles be used in the construction of offshore platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of offshore platforms. FRP pultrusion profiles have several advantageous properties that make them suitable for offshore applications. Firstly, FRP pultrusion profiles are lightweight yet strong, which is crucial for offshore platforms that need to withstand harsh environmental conditions such as strong winds, waves, and corrosive saltwater. The high strength-to-weight ratio of FRP makes it an ideal choice for reducing overall weight while maintaining structural integrity. Secondly, FRP is highly resistant to corrosion, unlike traditional construction materials such as steel. This is particularly important in the offshore environment, where saltwater exposure can lead to rapid corrosion of metal structures. FRP pultrusion profiles do not rust or corrode, resulting in longer service life and reduced maintenance costs. Furthermore, FRP pultrusion profiles can be designed and manufactured to have excellent fire resistance properties. This is crucial for offshore platforms, as fire incidents can have catastrophic consequences. FRP materials can be engineered to meet specific fire safety standards, providing an added layer of protection. Additionally, FRP pultrusion profiles offer design flexibility, as they can be easily customized to meet specific project requirements. This allows for the creation of complex shapes and sizes, enabling efficient construction and installation of offshore platforms. Overall, the lightweight, corrosion-resistant, fire-resistant, and customizable nature of FRP pultrusion profiles make them a suitable choice for the construction of offshore platforms. They offer numerous advantages over traditional materials, contributing to improved safety, durability, and cost-effectiveness in offshore construction projects.

- Q:Can FRP pultrusion profiles be used in the production of electrical busbars?

- Yes, FRP pultrusion profiles can be used in the production of electrical busbars. FRP (Fiber Reinforced Plastic) pultrusion profiles offer several advantages such as high strength, excellent electrical insulation properties, and resistance to corrosion, making them suitable for use in electrical applications like busbars. They provide a lightweight and durable alternative to traditional materials like copper or aluminum, and their non-conductive nature ensures safety in electrical systems.

- Q:Are FRP pultrusion profiles resistant to caustic solutions?

- Yes, FRP pultrusion profiles are generally highly resistant to caustic solutions. The inherent chemical resistance of fiberglass-reinforced plastic (FRP) combined with the corrosion-resistant properties of the pultrusion manufacturing process make FRP pultrusion profiles an excellent choice for applications involving caustic solutions.

- Q:Can FRP pultrusion profiles be used in the construction of elevated walkways?

- FRP pultrusion profiles have the capability to be utilized in the construction of elevated walkways. These profiles are not only lightweight, but they also possess significant strength, rendering them an optimal selection for the creation of walkways that are durable and have longevity, even when subjected to heavy foot traffic. Additionally, they provide exceptional resistance to corrosion, making them suitable for outdoor applications where exposure to moisture, chemicals, and UV radiation is a concern. Moreover, due to their high strength-to-weight ratios, FRP pultrusion profiles can be easily installed and lessen the structural load on the supporting elements. Furthermore, the non-conductive nature of FRP profiles make them a safer alternative for walkways in areas that are prone to electrical hazards. In summary, the advantages offered by FRP pultrusion profiles make them highly suitable for the construction of elevated walkways.

- Q:Are FRP pultrusion profiles resistant to hail or impact damage?

- FRP pultrusion profiles exhibit exceptional resistance to both hail and impact damage. The incorporation of reinforcing fibers such as carbon or glass, along with a polymer resin matrix, grants these profiles unparalleled strength and durability. When compared to materials like wood, steel, or aluminum, FRP pultrusions offer significantly superior impact resistance. These profiles are specifically engineered to endure even the harshest environmental conditions, including hailstorms. The composite composition of FRP enables it to effectively absorb and distribute the energy generated by impacts, effectively preventing the formation of cracks or fractures. As a result, they are an ideal choice for various applications that necessitate protection against hail or impact damage, such as building facades, bridges, handrails, and utility poles. Moreover, FRP pultrusion profiles possess an impressive strength-to-weight ratio, meaning they can withstand heavy impacts without undermining their structural integrity. Furthermore, they are non-corrosive, making them impervious to rust or degradation caused by hail or impact. To summarize, the composite construction and exceptional strength-to-weight ratio of FRP pultrusion profiles render them highly resistant to hail or impact damage. They offer a reliable and long-lasting solution for applications that demand durability and resilience in the face of harsh environmental conditions.

- Q:Can FRP pultrusion profiles be used in the construction of safety barriers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of safety barriers. FRP pultrusion profiles offer several advantages over traditional materials like steel or concrete when it comes to safety barrier applications. Firstly, FRP pultrusion profiles are incredibly strong and durable. They have high tensile strength, which means they can withstand heavy loads and impacts without deforming or breaking. This makes them suitable for withstanding the forces that safety barriers may encounter, such as vehicular collisions or other accidents. Secondly, FRP pultrusion profiles are lightweight. Compared to steel or concrete, FRP is significantly lighter, making it easier to transport, install, and handle during construction. The lightweight nature of FRP also reduces the overall weight of the safety barrier structure, which can be an advantage in terms of ease of installation and cost-effectiveness. Additionally, FRP pultrusion profiles have excellent corrosion resistance. Unlike steel, FRP is not susceptible to rust or corrosion, which can compromise the integrity and safety of the barrier over time. This makes FRP an ideal material for safety barriers that are exposed to outdoor environments or harsh weather conditions. Furthermore, FRP pultrusion profiles are non-conductive and non-magnetic, which can be advantageous in certain safety barrier applications. For example, in areas where electrical or magnetic interference is a concern, such as near power lines or sensitive equipment, FRP barriers can provide an extra layer of safety by avoiding any potential electrical or magnetic hazards. Overall, FRP pultrusion profiles offer a reliable and efficient solution for constructing safety barriers. Their strength, durability, lightweight nature, corrosion resistance, and non-conductive properties make them a suitable choice for a wide range of safety barrier applications.

- Q:Are FRP pultrusion profiles resistant to mold and mildew?

- Yes, FRP pultrusion profiles are highly resistant to mold and mildew. The non-porous nature of the fiberglass reinforcement and the synthetic resin matrix used in pultrusion manufacturing make these profiles highly resistant to moisture absorption, preventing the growth of mold and mildew.

- Q:Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP pultrusion profiles can be used in the construction industry. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability. These profiles can be used in various construction applications such as structural support systems, window and door frames, bridge components, and building facades. They provide a lightweight and cost-effective alternative to traditional construction materials like steel and concrete.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

insulation FRP grating corrosion resistence high strength SGS ISO9001 certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords