Insulation Bricks Refracotry Or Insulation Fire Brick High Quality 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

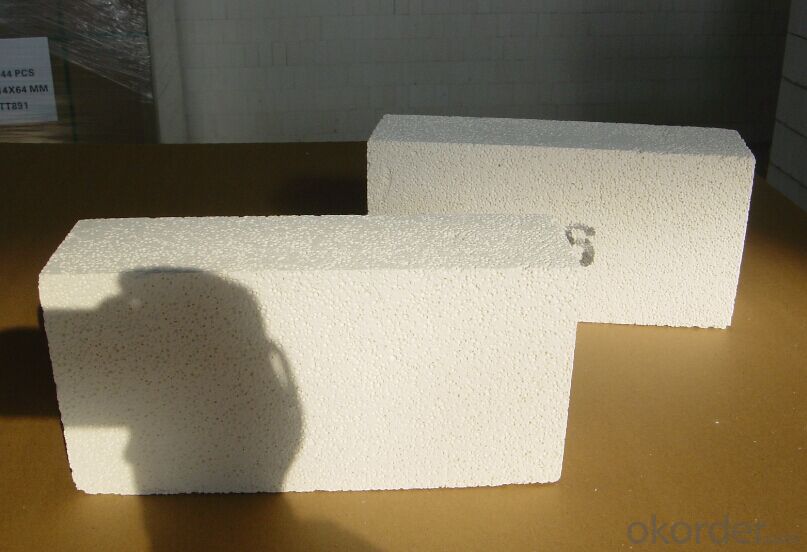

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can insulating fire bricks be used for kiln furniture?

- Yes, insulating fire bricks can be used for kiln furniture. Insulating fire bricks are designed to withstand high temperatures and are commonly used in industrial kilns and furnaces. They have excellent thermal insulation properties, which makes them ideal for creating kiln furniture such as shelves, posts, and supports. The insulating properties of these bricks help to distribute heat evenly throughout the kiln, ensuring that the items being fired are heated consistently. Additionally, insulating fire bricks are lightweight and easy to handle, making them a convenient choice for kiln furniture.

- Q:Material and making method of light insulating brick

- Thermal insulation brick is a new type of building material synthesized with macromolecule material. Replace the aluminum plate, honeycomb board, curtain wall and other commonly used decorative materials, multi-functional integration, a construction can solve the thermal insulation decoration two functional requirements, smooth, smooth and beautiful, decorative strong. Mainly used in toilets, kitchens, television, the background wall, bedroom, walls and so on. And brightly colored, various specifications, can be cut at random, the section neatly.

- Q:Can insulating fire bricks be used for insulation in boilers?

- Certainly, insulation in boilers can make use of insulating fire bricks. These bricks are specially engineered to endure extreme temperatures and offer exceptional thermal insulation. Their thermal conductivity is minimal, resulting in a significant decrease in heat dissipation and an enhancement in the energy efficacy of boilers. Moreover, insulating fire bricks are lightweight and simple to install, rendering them a favored option for boiler insulation. They aid in preserving elevated temperatures within the boiler, facilitating efficient combustion and heat transfer, while simultaneously shielding the outer framework from excessive heat. All in all, insulating fire bricks are a dependable and efficient alternative for boiler insulation.

- Q:Are insulating fire bricks suitable for use in steel manufacturing plants?

- Insulating fire bricks are a suitable choice for steel manufacturing plants. Their excellent thermal properties, including high heat resistance and low thermal conductivity, make them ideal for high-temperature environments like steel manufacturing plants. These bricks can endure the extreme heat generated during steel production processes such as melting, casting, and forging. Furthermore, they assist in conserving energy by minimizing heat loss, thereby enhancing the overall efficiency of the plant. Additionally, they possess considerable mechanical strength and can withstand the physical stresses and strains associated with steel manufacturing operations. In summary, incorporating insulating fire bricks in steel manufacturing plants can enhance safety, boost productivity, and improve energy efficiency.

- Q:Are insulating fire bricks suitable for thermal insulation in boilers?

- Yes, insulating fire bricks are suitable for thermal insulation in boilers. They have high thermal conductivity and can withstand high temperatures, making them an effective choice for insulating the walls and floors of boilers. Their ability to retain heat helps in improving energy efficiency and reducing heat loss, ultimately enhancing the overall performance of the boiler system.

- Q:Can insulating fire bricks be used for insulation in heat treatment furnaces?

- Yes, insulating fire bricks can be used for insulation in heat treatment furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity and can effectively retain heat within the furnace. Additionally, their lightweight nature makes them easy to handle and install. Insulating fire bricks are commonly used in various heat treatment applications, such as annealing, tempering, and hardening processes, to ensure optimal heat retention and energy efficiency in the furnace.

- Q:What is the recommended curing method for insulating fire bricks?

- The recommended curing method for insulating fire bricks is to gradually heat them up to their operating temperature over a period of time. This can be done by starting with a low temperature and gradually increasing it over several hours or days, allowing the bricks to slowly expand and release any moisture or volatile substances. This process helps to prevent thermal shock and ensures the bricks are properly cured and ready for use.

- Q:What is composite sintering insulation bricks?

- Taking the Yangtze River, lake and silt as the main raw materials, the performance indexes of roasting are in line with the technical specifications and technical requirements of the building blocks, referred to as insulating bricks.

- Q:Are insulating fire bricks resistant to acid or alkali attacks?

- Insulating fire bricks are generally resistant to acid attacks, as they are made from materials such as alumina and silica, which have high resistance to acids. However, their resistance to alkali attacks may vary depending on the specific composition of the bricks and the concentration of the alkali solution. Some insulating fire bricks may exhibit good resistance to alkali attacks, while others may be more susceptible to degradation in the presence of alkali substances. It is important to consult the manufacturer or refer to the specific product specifications to determine the level of resistance to acid or alkali attacks for a particular type of insulating fire brick.

- Q:Are insulating fire bricks suitable for use in coke ovens?

- Yes, insulating fire bricks are suitable for use in coke ovens. These bricks are designed to withstand high temperatures and provide excellent insulation properties, making them ideal for use in coke ovens where extreme heat is generated during the coking process. They help to maintain the desired temperature inside the oven and prevent heat loss, resulting in improved energy efficiency and reduced fuel consumption. Additionally, insulating fire bricks have good resistance to chemical reactions and thermal shock, which further enhances their suitability for use in coke ovens.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulation Bricks Refracotry Or Insulation Fire Brick High Quality 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords