Insulation Bricks Or Insulation Fire Brick High Quality 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

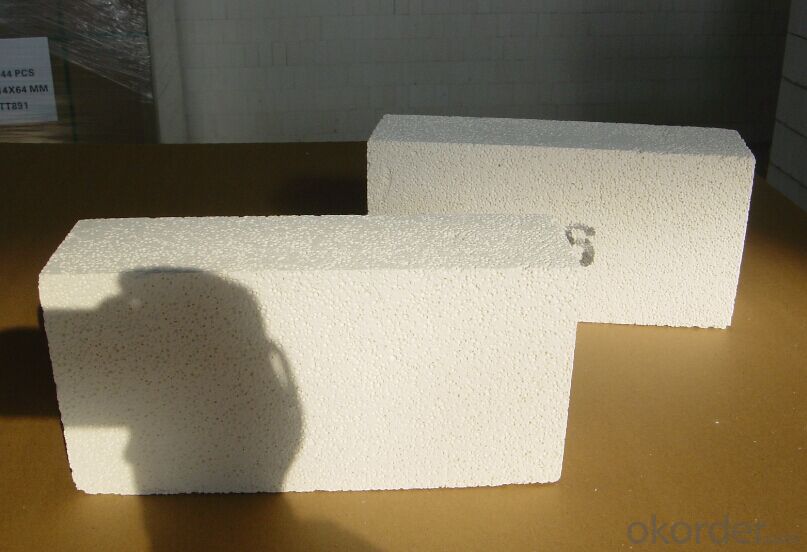

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What is the average density of insulating fire bricks?

- The average density of insulating fire bricks can vary depending on the specific composition and manufacturing process. However, in general, insulating fire bricks have a lower density compared to regular bricks. The average density of insulating fire bricks typically ranges from 0.6 grams per cubic centimeter (g/cm³) to 1.5 g/cm³. This lower density is achieved by incorporating lightweight materials or by introducing air pockets during the manufacturing process. The lower density of insulating fire bricks allows them to provide excellent thermal insulation properties, making them ideal for applications where high temperatures need to be contained while minimizing heat loss.

- Q:Are insulating fire bricks suitable for use in the construction of drying ovens?

- Yes, insulating fire bricks are suitable for use in the construction of drying ovens. They have excellent thermal insulation properties, which helps to retain heat and prevent heat loss during the drying process. Additionally, insulating fire bricks can withstand high temperatures and have good resistance to thermal shocks, making them a reliable choice for drying oven construction.

- Q:Can insulating fire bricks be used as a heat shield?

- Yes, insulating fire bricks can be used as a heat shield. They have excellent thermal insulation properties and can withstand high temperatures, making them an ideal choice for protecting against heat radiation and transferring minimal heat to the surrounding areas.

- Q:Can insulating fire bricks be used as a refractory lining material?

- Yes, insulating fire bricks can be used as a refractory lining material. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for applications where heat retention and energy efficiency are important. They are commonly used in furnaces, kilns, and other high-temperature industrial equipment as a lining material to prevent heat loss and protect the surrounding structures.

- Q:Can insulating fire bricks be used in high-temperature ducts?

- High-temperature ducts can indeed utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures, making them an optimal option for situations where heat retention and insulation are pivotal. Through their low thermal conductivity and strong resistance to thermal shock, insulating fire bricks are able to effectively trap heat within the ducts, averting any energy loss and ensuring efficient heat transfer. Moreover, their lightweight composition facilitates easy installation and handling, while their durability enables them to withstand the demanding conditions of high-temperature environments. Ultimately, insulating fire bricks prove themselves as a dependable and efficacious solution for the insulation of high-temperature ducts.

- Q:What are the bubble bricks?

- The steam free aerated block has the advantages of wide raw material sources, high waste rate and low cost. With fly ash, slag, sand, sand, soil containing low amount of powder and tailings as the main raw materials (with one can), local materials, low cost, high profit.

- Q:Can insulating fire bricks be used in blast furnaces?

- Insulating fire bricks have the capability to be utilized in blast furnaces. These bricks are specifically designed to endure high temperatures and provide exceptional thermal insulation. Blast furnaces operate under extreme temperatures, typically reaching around 1500°C (2732°F), and thus require materials that can withstand such harsh conditions. Insulating fire bricks are constructed from lightweight substances like ceramic fibers, which possess low thermal conductivity and effectively retain heat. This makes them highly suitable for lining the walls and roofs of blast furnaces as they aid in energy conservation, minimize heat loss, and enhance overall furnace efficiency. Moreover, the use of insulating fire bricks in blast furnaces also serves to safeguard the structural integrity of the furnace by reducing thermal stress and preventing excessive heat transfer to the surrounding environment. Ultimately, the incorporation of insulating fire bricks in blast furnaces contributes to enhanced performance, energy preservation, and prolonged furnace lifespan.

- Q:How do insulating fire bricks handle moisture?

- Insulating fire bricks are designed to handle moisture quite effectively. They have low porosity and are made of materials that are resistant to water absorption. This allows them to retain their structural integrity even when exposed to moisture or high humidity levels. Additionally, their insulating properties are not significantly affected by moisture, making them suitable for various applications where moisture resistance is required.

- Q:Do insulating fire bricks require a refractory mortar for installation?

- Yes, insulating fire bricks typically require a refractory mortar for proper installation. Insulating fire bricks are lightweight and have high insulating properties, making them ideal for applications where thermal efficiency is important. However, due to their lightweight nature, they can be more fragile and prone to cracking or breaking under stress. Using a refractory mortar specifically designed for high-temperature applications helps ensure a strong and durable bond between the bricks. Refractory mortars are formulated to withstand high temperatures and provide excellent adhesion and thermal expansion properties. This mortar helps to create a solid and secure structure by filling in gaps between the bricks and providing additional support. Without the use of refractory mortar, insulating fire bricks may not be properly secured and could shift or separate over time, compromising the integrity of the installation. Additionally, the absence of refractory mortar may result in reduced thermal efficiency due to increased heat loss through gaps and spaces between the bricks. Therefore, it is highly recommended to use a refractory mortar when installing insulating fire bricks to ensure a strong and long-lasting construction.

- Q:Can insulating fire bricks be used in lime plants?

- Indeed, insulating fire bricks have the capability to be utilized in lime plants. These bricks are uniquely crafted to possess a remarkably low thermal conductivity, thus enabling them to effectively impede the transfer of heat. In the context of lime plants, where elevated temperatures are necessary for the calcination process, insulating fire bricks can be employed to line the kilns and other zones exposed to high temperatures. By doing so, these bricks aid in the preservation of heat within the lime kilns, resulting in a reduction of energy loss and an enhancement of overall efficiency. Furthermore, insulating fire bricks possess resistance against chemical attacks and are able to endure the harsh conditions experienced in lime plants, rendering them a suitable and appropriate choice for this particular application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulation Bricks Or Insulation Fire Brick High Quality 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords