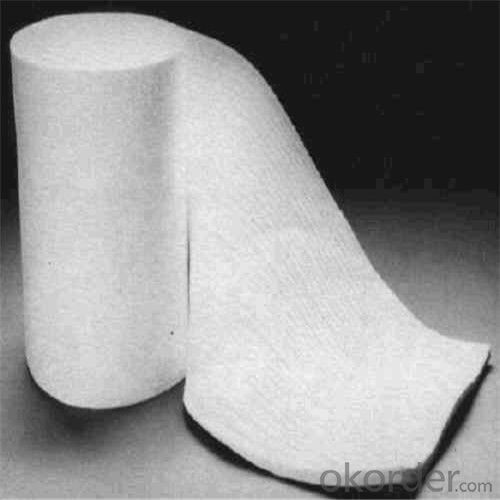

Insulation Alumina Silicate Ceramic Fiber Blanket

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details for Insulation Alumina Silicate Ceramic Fiber Blanket

| rade: | HA (High Aluminum) | Application: | Liners Of Industrial Furnace,pizza oven | Thickness: | 10-50mm |

| Width: | 610/1220mm | Length: | 3000-14400mm | Chemical Composition: | ZRO2 AL2O3 SIO2,ZRO2+AL2O3+SIO2;99% |

| Ultimate Strength (≥ MPa): | 0.04 | Working Temperature: | 1300C | Fiber Diameter: | 3um |

| Shrinkage (1800 ℉, 3h): | -3 | Thermal Conductivity: | 0.045-0.200 | Density (kg/m³ ): | 128 |

| Model Number: | YXTX-422 | Brand Name: | Place of Origin: | (Mainland) | |

| color: | white | port: | qingdao | packing: | plastic bags inside,woven bags outside |

| working temp: | 1300C | classification temp: | 1400C | specification: | according to your requirments |

| name: | ceramic fiber blanket for boiler insulation |

Packaging & Delivery

| Packaging Detail: | plastic bags inside,woven bags outside |

| Delivery Detail: | within 10 days after deposit |

Specifications

insulation ceramic fiber blanket

1.working temp;1300C

2.density:128kg/m3

3.specification:50mm*610/1220*5m

Product Description

Alumina silicate ceramic fiber blanket

Product Series:

1.1050 Ceramic Fiber Spun Blanket YXTX-112

2.1260 Ceramic Fiber Spun Blanket YXTX-212

3. High Purity Ceramic Fiber Spun Blanket YXTX-312

4.High Aluminum Ceramic Fiber Spun Blanket YXTX-422

5.High Zirconium Ceramic Fiber Spun Blanket YXTX-512

Description:

1.Ceramic Fiber Blanket was adopted continuous processing method,the fiber interweaved shapely after being needled,which of excellent tensile strength. The blanket contains not any bonding agent .

2.Our needled blanket has various density and thickness so that our client can have many choices, which will bring the perfect insulating framework and profit.

3.Ceramic Fiber Blanket can resist the chemical species well, but not the Hydrofluoric Acid, Phosphoric Acid and Strong Base.

4.Ceramic Fiber Blanket have excellent capability of resisting the oil, after being dried it will repossess the thermal characteristic and the physical feature.

Characteristic:

1.Excellent Chemical Stability

2.Excellent Thermal Stability

3.Excellent Tensile Strength

4.Low Thermal Conductivity

5.Low Heat Storage

Application:

1.The material of wall lining and back lining of industrial furnace and the sealing and insulation material of expanded gaps of furnace wall, furnace door, furnace top lid, etc.

2.Insulating material of high temperature

3.Excellent materials to produce module and folded module

Technical Index:

Classification Temperature | 1050 | 1260 | 1400 | |||||||

Code | TXTX-112 | TXTX-212 | TXTX-312 | TXTX-422 | TXTX-512 | |||||

Shrinkage on Heating (%) | 950°C×24h≤-3 | 1000°C×24h≤-3 | 1100°C×24h≤-3 | 1200°C×24h≤-3 | 1350°C×24h≤-3 | |||||

Theoretical Thermal Conductivity (W/m·k) (128kg/m3) | 0.09(400°C) 0.176(800°C | 0.09(400°C) 0.176(800°C | 0.09(400°C) 0.176(800°C) 0.22(1000°C) | 0.132(600°C 0.22(1000°C | 0.76(600°C) 0.22(1000°C) | |||||

Theoretical Density (kg/m3) | 64/96/128 | |||||||||

Specification (mm) | 7200/5000/3600/3000×610/1220×/20/30/40/50 According to your requirements | |||||||||

Tensile Strength (Mpa)(128kg/m3) | 0.08-0.12 | |||||||||

AL2O3 (%) | ≥44 | ≥45 | ≥45 | 52~55 | 38~40 | |||||

ZrO2 | - | 15~17 | ||||||||

AL2O3+SiO2 (%) | ≥96 | ≥97 | ≥99 | ≥99 | — | |||||

AL2O3+SiO2+ZrO2 (%) | — | — | — | — | ≥99 | |||||

Fe2O3(%) | ≤1.2 | ≤1.0 | ≤0.2 | ≤0.2 | ≤0.2 | |||||

K2O+Na2O(%) | ≤0.5 | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | |||||

Package | Plastic Bag Inside, Woven Bags Outside | |||||||||

Quality Control System | ISO9001-2000, ISO14001-1996 | |||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

- Q:HVAC Experts - I need some help?

- there is no such thing as uv sensitive yarn

- Q:it's winter here and it's getting really cold,i did what i had to do with the cage to keep it good but do u think that making something for her would be useful??like something simple from wool??thanx 4 ur time and ty in advance

- My mother chose the names of her nine babies like most others doFor one particular baby she had chosen the name Janet prior to going to deliverWe were French speakers so that in itself was a little oddAnyways after the birth when they came with the forms she changed her mind and called her another name which escapes my memory at this timeThe baby died a couple days laterShe then gave the name Janet to a subsequent childBy the way my mother`s mother was also one such subsequent child but both had the same name (Lumina) and the first one died prior to the age of fiveShe might also have only been a couple days oldThe family tree that I saw did not specify her age of death and the second Lumina was the next one bornI guess she was not superstitious at all and may have thought she was giving this soul a second chanceI do believe that our names influence our lives and I even do not argue with the idea that our future lives may influence the choosing of our names since on some level involved in the choosing may be influenced by a timeless knowingCheers!!

- Q:I have wavy hair it's sooo annoying cuz it's not straight or curlyAnyway I straighten it everyday and I'm afraid I'll ruin it! Does anyone know of any hair products i can use to protect my hair from getting too damaged? Something that wont make it look greasy?

- Just cover them with water and BOIL themPlain and simple

- Q:Own a house where the previous owner closed in the garage to make a media roomThere is no insulation in attic or walls (I live in South Mississippi)Ducts had been run from the central AC to the addition, but when summer comes, the AC goes out all the time trying to cool the extra (uninsulated) loadThe HVAC people suggested insulating as much as possible (duh), closing off the ducts to the addition (so the AC only runs it's proper load), and adding a heating/cooling unit (like in a hotel) to the garage/media room.What experiences (good or bad) have people had with various units? Friedrichs, Amana, GE, etcGoing to ask the HVAC folks, as well as insulating folks, but want to get as much opinion as possible.Thanks

- NO, HIGHWAY DOES NOT MADE OF COMPUTERS , IT IS MADE OF STEEL BAR AND CONCRETES.

- Q:I was at school and my first class hasn't even started (So it was about 8 in the morning), and I had to go to the nurseI have stomach pains almost constantlyI have one almost every day, and I know that's not normalI can never use the bathroom eitherIt just does not work, and if it did it wouldn't helpThe nurse told me to look into eating more high-fiber foods which will help clean out my systemCan someone list anything that is high in fiber, but still good to eat? I know apples have fiber (The skin), and I enjoy thoseI love fruitsAny yogurt? does anyone have a diet plan that would be good for me? I know everyone is an individual, remember I'm 12Answer back as soon as possible please, Thanks.

- broccoli, spinach, swiss chard, green peas and other dark green leafy vegetables dried peas and beans such as kidney beans, lima beans, black-eyed beans, chick peas and lentils dried fruits such as apricots, dates, prunes and raisins berries such as blackberries, blueberries, raspberries and strawberries oranges, apple with skin, avocado, kiwi, mango and pear whole grain breads, buns, bagels, muffins breakfast cereals with at least 5 g of fiber per serving such as All Bran, Fiber One, Smart Bran, and Go Lean Cooked cereal such as Red River and Oat Bran whole-wheat pastas whole grains such as barley, popcorn, corn and brown rice I would like to know why you think using the bathroom will not help? If it is not a digestive problem then high fiber food won't help eitherIf it is a female problem you need to go to a gynecologistPerhaps your period is about to start.

- Q:Huswiferyby Edward Taylor Make me, O Lord, thy Spinning Wheele compleat; Thy Holy Worde my Distaff make for meeMake mine Affections thy Swift Flyers neate, And make my Soule thy holy Spoole to bee My Conversation make to be thy Reele, And reele the yarn thereon spun of thy WheeleMake me thy Loome then, knit therein this Twine: And make thy Holy Spirit, Lord, winde quills: Then weave the Web thyselfeThe yarn is fine Thine Ordinances make my Fulling Mills Then dy the same in Heavenly Colours Choice, All pinkt with Varnish't Flowers of ParadiseThen cloath therewith mine Understanding, Will, Affections, Judgment, Conscience, Memory; My Words and Actions, that their shine may fill My wayes with glory and thee glorify Then mine apparell shall display before yee That I am Cloathd in Holy robes for glory.~Im trying to annotate it so if someone could help me with what each stanza generally means that would be great :)

- When you bought the bracelet, Was there a silver cleaning cloth? Just use it.My bracelet is Soufeel ,it's much cheaper than Pandoraand cleaning easy just use the cleaning clothIt won't ruining the bracelet but you 'better put the charms off.May my answer can help you.

- Q:Is it possible to purchase a sample of the material used on the space shuttles thermal protection system?

- I don't think soHowever, you can contact the NASA Information Center and ask them for detailed information on the materialTo do any precise investigations you will of course need to become completely familiar with ceramics and the mechanics of heat transfer in solidsThat information will help you understand the pros and cons of various material mixes which have been tested and discarded as possible heat shield materialsWere you to be interested in conducting tests of various things you can obtain locally, you would need a very accurate high temperature thermometer, a blow torch, and various samples of ceramic and porcelan materials that you can obtain in your areaYou might look at sources like junk yards near you and old electrical materials placesHeat the outside of the ceramic and measure the temperature of the backside of the ceramic after a set time limit.say 1 minute, then 2 minutes, etcYou could then produce a test report analysis of the things you testedRegards, Zah

- Q:I have forced air heat and i want to insulate the air ducts, which insulation should i buy?

- There are special types for insulating hte insides of HVAC ductsThey are either rigid fiberglass or mineral wool that has an outer wrapping on itPermacote Linacoustic by Johns Manville is a good example.

- Q:Im was planning on getting 4 cerwin vega VE-15F's and 4 cerwin vega VE-12F's for a kickas system.but what would be better the VE or CLS line.Thanks! (cerwin vega for life!)

- I'm not too sure what U R asking-? I have pretty good experience w/ C.VHowever; the tweeters have been known to fail after a night of jamming until the bar closedThe Cable, Or the Speaker? I would use 10 AWG Extension Cord for any appor gig that will require a long runIt is a lot cheaper than Monster Cable, and has better insulationThe Speaker? That depends on your needs: The size of your room, the Furniture in said room, and your NeighborsFeel free 2 e-me! I hope this will help you save time and money!

- Q:Why are high fiber such as fruits, vegetables, and complex carbs considered quot;healthyquot; if they make you crap?

- Ingredients 8 chicken drumsticks 1/2 cup real mayonnaise 3 tablespoons mustard 1/4 cup grated parmesan cheese 1 teaspoon Italian seasoning 1/2 teaspoon garlic powder 1/2 teaspoon black pepper 1 cup fresh bread crumbs Directions 1Rinse and pat drumsticks dry2Combine mustard and mayonnaise together in one bowl3In a separate bowl mix bread crumbs, parmesan, Italian seasoning, garlic powder and black pepper4Using a pastry brush coat a drumstick liberally with the mayonnaise mustard mixture then roll in the bread crumbs to coat well5Lay the coated drumstick on a baking sheet then repeat with remaining drumsticks6Bake at 350 for 45 minutes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulation Alumina Silicate Ceramic Fiber Blanket

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords