Insulating Refractory Bricks High-Alumina Brick for Furnace Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

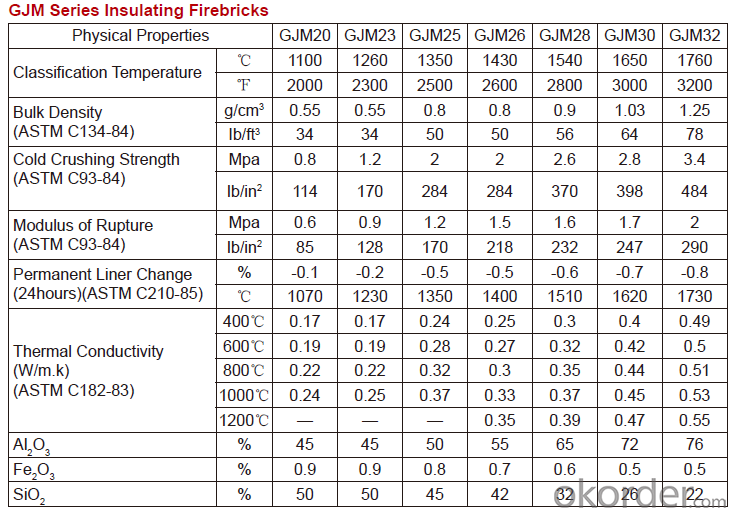

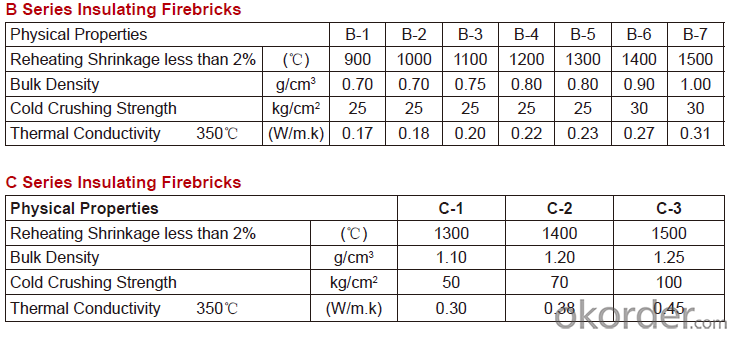

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:Do insulating fire bricks require maintenance?

- Yes, insulating fire bricks do require maintenance. While they are known for their durability and ability to withstand high temperatures, regular maintenance is necessary to ensure their optimal performance and longevity. One key aspect of maintenance is periodic cleaning. Over time, insulating fire bricks can accumulate dust, soot, and other debris, which can affect their insulating properties. Therefore, it is recommended to clean the bricks regularly to remove any build-up. This can be done using a soft brush or a mild cleaning solution. Another important aspect of maintenance is checking for any cracks or damages. Inspecting the bricks for any signs of wear and tear is crucial to identify and address any issues before they worsen. Cracks or damages can compromise the bricks' insulation and stability, so they should be repaired or replaced as needed. Furthermore, it is important to monitor the condition of the mortar or refractory cement used to hold the insulating fire bricks together. Over time, the mortar can deteriorate due to exposure to heat and other elements. Regularly inspecting and repairing any damaged mortar helps to maintain the structural integrity of the fire bricks. In addition to these maintenance tasks, it is essential to follow the manufacturer's instructions and recommendations for the specific type of insulating fire bricks used. This may include guidelines for installation, temperature limits, and any other specific care instructions. Overall, while insulating fire bricks are durable, regular maintenance is necessary to ensure their optimal performance and prolong their lifespan. Proper cleaning, inspecting for damage, and following manufacturer's guidelines are key components of maintaining insulating fire bricks.

- Q:Can the whole wall of the high-rise building be made of grey insulation bricks?

- If the frame structure, it may be so. What is the length of the whole wall? If it is longer, it is necessary to make a constructional column; if the hole is larger, the edge of the hole needs to be made into a border or a constructional column; if the entrance is small, the edge of the hole is about 300mm and needs solid bricks to build better. South wall thickness can be about 190mm, plus plastering design value of 200mm. Personal comments for reference!

- Q:Can insulating fire bricks be used for insulation in sewage treatment plants?

- Insulating fire bricks are capable of being utilized for insulation purposes in sewage treatment plants. Specifically designed to endure elevated temperatures and deliver exceptional insulation, these bricks prove to be suitable for deployment in environments characterized by heat and moisture, such as sewage treatment plants. With their low thermal conductivity, they aid in diminishing heat loss and enhancing energy efficiency throughout the treatment procedure. Furthermore, their resistance to chemicals and moisture renders them ideal for enduring the corrosive surroundings typically encountered in sewage treatment plants. Consequently, the usage of insulating fire bricks effectively ensures insulation in sewage treatment plants, thereby aiding in the preservation of optimal operating temperatures and the enhancement of overall efficiency.

- Q:What bricks are thermal insulation bricks?

- Thermal insulation brick is a new type of building material synthesized with macromolecule material. Grey, hollowed out bricks are basically.

- Q:Can insulating fire bricks be used in low-temperature applications as well?

- Yes, insulating fire bricks can be used in low-temperature applications. Insulating fire bricks are designed to have high thermal insulation properties, which means they can effectively prevent heat transfer. This makes them suitable for use in both high-temperature and low-temperature environments. In low-temperature applications, insulating fire bricks can help to minimize heat loss and maintain a stable temperature. They can be used to insulate walls, floors, and roofs of structures or equipment that require temperature control, such as cold storage facilities, refrigerators, or freezers. Insulating fire bricks are also commonly used in low-temperature furnaces and kilns, where they help to minimize energy consumption and maintain a consistent temperature throughout the heating process. Their high insulating properties ensure that the heat generated inside the furnace or kiln is effectively contained, reducing heat loss and improving overall energy efficiency. Furthermore, insulating fire bricks are lightweight and easy to handle, making them convenient for various low-temperature applications. They are also resistant to thermal shock and offer excellent structural stability, ensuring long-lasting performance even in challenging environments. Overall, insulating fire bricks can be effectively utilized in low-temperature applications to enhance energy efficiency, temperature control, and structural stability.

- Q:How do insulating fire bricks prevent heat loss?

- Insulating fire bricks have been specifically engineered to prevent the loss of heat in a wide range of applications. These bricks are crafted from refractory materials that possess exceptional thermal insulation properties. Their structure contains small air pockets that serve to minimize the transfer of heat through conduction and convection. One effective method employed by insulating fire bricks to prevent heat loss involves their low thermal conductivity. When compared to other materials, these bricks exhibit significantly lower thermal conductivity, which means they are less efficient at transmitting heat. This characteristic enables them to function as a barrier, impeding the transfer of heat from one side of the brick to the other. Moreover, the presence of tiny air pockets within the bricks creates a thermal barrier. Due to the poor heat-conducting properties of air, these air pockets effectively trap heat within the brick, preventing its escape. This insulation property aids in retaining heat within the desired area, thereby reducing heat loss and enhancing energy efficiency. Furthermore, insulating fire bricks possess the ability to prevent heat loss through heat reflection. These bricks boast a high emissivity, enabling them to reflect a considerable amount of heat back into the desired space. This reflection works to maintain a higher temperature within the area and prevent the dissipation of heat. In conclusion, insulating fire bricks effectively prevent heat loss by diminishing conduction and convection through their low thermal conductivity, confining heat within small air pockets, and reflecting heat back into the desired space. These bricks play an indispensable role in diverse applications where heat retention is of utmost importance, such as kilns, furnaces, and other high-temperature environments.

- Q:Can insulating fire bricks be used in the construction of steam boilers?

- Yes, insulating fire bricks can be used in the construction of steam boilers. Insulating fire bricks are made from lightweight refractory materials that have excellent thermal insulation properties. They are designed to withstand high temperatures and provide insulation in industries where heat retention is crucial, such as steam boiler construction. Insulating fire bricks have low thermal conductivity, which means they can effectively minimize heat loss and improve energy efficiency in steam boilers. By using these bricks in the construction of steam boilers, the overall heat transfer efficiency can be increased, resulting in reduced fuel consumption and lower operating costs. Furthermore, insulating fire bricks have good resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. This is important in steam boiler applications, where the temperature can fluctuate significantly during operation. In summary, insulating fire bricks are a suitable choice for steam boiler construction due to their excellent thermal insulation properties, low thermal conductivity, and resistance to thermal shock. They can help improve energy efficiency, reduce fuel consumption, and ensure the longevity of the boiler.

- Q:Can insulating fire bricks be used in the construction of thermal insulation roofs?

- Yes, insulating fire bricks can be used in the construction of thermal insulation roofs. These bricks are designed to have high thermal resistance and low thermal conductivity, making them suitable for insulating applications. They can help reduce heat transfer and improve energy efficiency in roofs by providing effective insulation.

- Q:Can insulating fire bricks be used in high-temperature kilns and furnaces?

- Yes, insulating fire bricks are commonly used in high-temperature kilns and furnaces. These bricks have excellent thermal insulation properties, which allow them to withstand and retain high temperatures. They are designed to minimize heat loss and improve energy efficiency in such environments.

- Q:Are insulating fire bricks resistant to chlorine gas?

- Yes, insulating fire bricks are resistant to chlorine gas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulating Refractory Bricks High-Alumina Brick for Furnace Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords