Insulating Glass 2-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

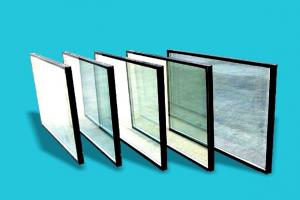

Insulating Glass is made up of two or more pieces of glass which are separated by metal frames, its edge is sealed with the glue by way of jointing and welding.

Features:

1. Heat preservation and energy conservation

2. Anti-frost and anti-dewing

3. Sound insulation

4. The aluminum bar is bent automatically. Automatic molecular-sieve filling system, vertical coupling and vertical automatic sealing can guarantee the production of high-quality insulating glass technically.

5. Compared with common insulating glass, the sealing is reliable for homogenous coating with no bulbs between the layers.

6. good appearance, good dew point

Specifications:

Thickness: 2-19mm

Size:

2500*5000mm(Max)

250*300mm(Min)

Applications:

Insulating Glass is mainly used as building glass in curtain wall, glass doors and windows, etc.

- Q:Aluminum alloy window glass tape, how fast loading?

- The inside mounting method is opposite to the outside installation method, that is, the operator stands on the indoor floor or indoor high stool to install the glass of the aluminum alloy door and window. In the first window in the fixed slot lateral seal, safety glass, positioning, and then fixed to the inside of the notch is injected in the cavity joint sealant fixed, which is dry and wet two kinds of material mixed use practices.

- Q:What are the anticorrosive materials for glass fiber reinforced plastic?

- Finished product protection: because the construction environment belongs to the pool irrigation, it is not conducive to the curing of epoxy forming, so it must take 48 hours curing time, to be fully cured after use.

- Q:Can the toughened glass be cracked by the sun?

- high strengthThe toughened glass of the same thickness has 3~5 times the impact strength of ordinary glass, and the bending strength is 3~5 times of that of ordinary glass.

- Q:How is glass made? What are the main ingredients?

- Preparation of batch. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..

- Q:What are the construction principles and raw materials of tempered glass?

- Tempered glass is the two processing product of flat glass. The processing of toughened glass can be divided into physical toughening method and chemical toughening method. Physical toughened glass is also called tempered tempered glass. It is the ordinary flat glass in heating furnace heated to the softening temperature close to the glass (600 DEG C), the internal stress of the self deformation is eliminated, and then removed from the glass furnace, with long nozzle high pressure cold air blowing glass on both sides, the rapid and uniform cooling to room temperature, well tempered glass can be made. This kind of glass in the internal and external tension compression stress state, once the local damage occurs, the stress release, the glass is broken into small pieces, these small pieces no sharp edges, not easy to hurt. In the production of tempered glass, the most influential factor on the quality of the product is how to make the glass form a larger and uniform internal stress. But the greatest impact on yield is how to prevent cracking and deformation.

- Q:Is the balance pad the raw material in the motor?

- Its main function is the use of mechanical energy into electrical energy, the most common is the use of thermal energy, water power, and so on to promote the generator rotor to generate electricity.

- Q:Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Generally finished products are not harmful, and there is contamination in the making process. 2. glaze mainly by quartz, feldspar, kaolin and other chemical raw materials.

- Q:Which is the best solar water heater tube?

- The color of the vacuum heat collecting tube is mainly blue and black, and the overall chromatic aberration is small. But black does not indicate the quality of vacuum heat collecting tube is good, because some manufacturers in order to cover up variegated, often made of pure black film. In fact, there is a certain error in the color of the vacuum heat collecting tube, which is unavoidable, and does not affect the heat collecting efficiency of the vacuum heat collecting tube.

- Q:What kind of material is made of automobile glass?

- Compared with ordinary glass, automotive glass is glass, broken is very small granular, may reduce damage. Automobile front windshield PVB interlayer, strong ability uprising.

- Q:Is the production of glass materials as thin as possible? Why?

- Absolutely not!

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | Southeast Asia; Mid-East; Africa |

| Company Certifications | CE;RoHS;ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Insulating Glass 2-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches