Insulating Fire Brick IFB Straights for Ceramics Industries

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What it the Insulating Fire Brick?

Insulating fire bricks (IFBs) are called soft bricks comparing to hard bricks or Fireclay bricks and they are light in weight. Insulating fire brick can be easily cut by handheld hack saw or other hand tools like chisel. Insulating firebricks have high porous rate and have excellent insulating properties.

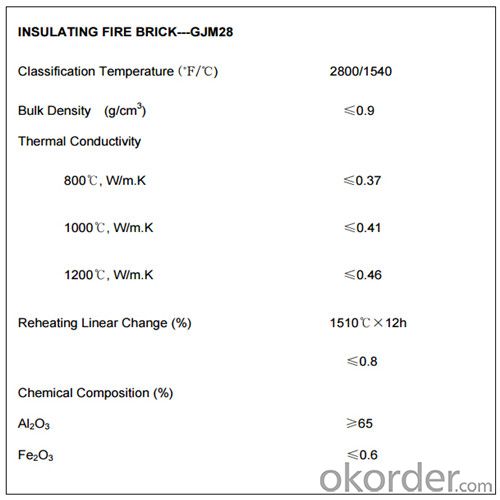

Technical Data of Insulating Fire Brick

What are the excellent features of Insulating Fire Brick?

High heat resistance and durability

Excellent insulating properties

Excellent resistance to thermal shock

Low thermal conductivity

Low heat storage

Excellent construction/compressive strength

Particularly suited to highest temperature applications above 1600°C or 2800°F

Structural integrity capable of dealing with erosive and abrasive environments

Low impurity

Precise dimensions

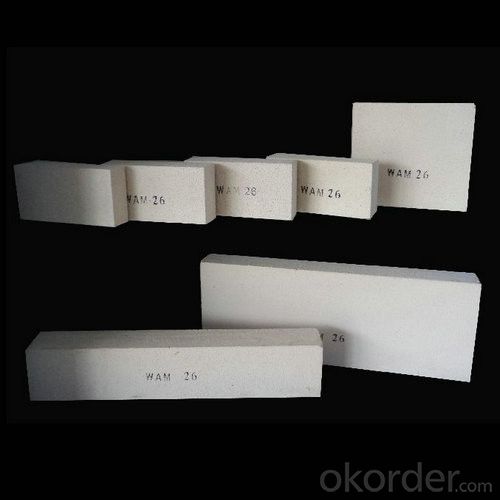

Image of Insulating Fire Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q:Can insulating fire bricks be used in the construction of lime production ovens?

- Yes, insulating fire bricks can be used in the construction of lime production ovens. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for the intense heat and thermal requirements of lime production ovens. They help maintain consistent temperature levels, reduce heat loss, and improve energy efficiency, making them a reliable choice for such applications.

- Q:Can insulating fire bricks be used as a thermal barrier?

- Yes, insulating fire bricks can be used as a thermal barrier. These bricks have high thermal resistance and low thermal conductivity, making them effective in reducing heat transfer. They are commonly used in applications where thermal insulation is required, such as in furnaces, kilns, and fireplaces, to prevent heat loss and protect surrounding areas from excessive heat.

- Q:Can insulating fire bricks be used for fireplace lining?

- Yes, insulating fire bricks can be used for fireplace lining. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation. They have a low thermal conductivity, which means they can effectively retain heat and prevent excessive heat loss from the fireplace. This makes them an ideal choice for lining fireplaces as they help to increase the efficiency and effectiveness of the heating system. Additionally, insulating fire bricks are also resistant to thermal shock and can withstand rapid temperature changes, which is important in a fireplace where the temperature can fluctuate significantly. Overall, using insulating fire bricks for fireplace lining can improve the performance and energy efficiency of the fireplace while ensuring safety and durability.

- Q:Are insulating fire bricks suitable for use in blast furnaces?

- No, insulating fire bricks are not suitable for use in blast furnaces. Blast furnaces require refractory bricks that can withstand extremely high temperatures and harsh conditions, whereas insulating fire bricks are designed for lower temperature applications.

- Q:Can insulating fire bricks be used in refractory castings?

- Indeed, refractory castings can incorporate insulating fire bricks. Due to their lightweight nature and exceptional insulation abilities, insulating fire bricks are ideal for tasks that demand thermal insulation. Such tasks include the creation of linings in furnaces, kilns, and other equipment that operates at high temperatures. To achieve thermal insulation and minimize heat loss, insulating fire bricks can be utilized either as a layer or as an element within the refractory casting mixture. Furthermore, their low thermal conductivity aids in reducing energy consumption and sustaining elevated temperatures within the casting.

- Q:Can insulating fire bricks be used in the construction of heat exchangers?

- Yes, insulating fire bricks can be used in the construction of heat exchangers. These bricks are designed to withstand high temperatures and have excellent insulating properties, making them suitable for heat exchanger applications where heat retention and insulation are important.

- Q:Can insulating fire bricks be used in the construction of metal smelting molds?

- Yes, insulating fire bricks can be used in the construction of metal smelting molds. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in smelting processes where extreme heat is required. These bricks have excellent thermal insulation properties, which help to retain the heat and minimize heat loss during the smelting process. This is important for maintaining a consistent temperature within the mold, ensuring efficient and successful metal smelting. Additionally, insulating fire bricks are lightweight and easy to handle, making them a practical choice for constructing molds. Overall, insulating fire bricks are a reliable and effective option for constructing metal smelting molds.

- Q:Can insulating fire bricks be used for insulation in furnaces?

- Yes, insulating fire bricks can be used for insulation in furnaces. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in furnaces to reduce heat loss and increase energy efficiency.

- Q:Is it possible to recycle used insulating fire bricks?

- It is indeed feasible to recycle insulating fire bricks that have been used. Insulating fire bricks consist of a range of materials, including alumina, silica, and other refractory materials. These materials can be dismantled and utilized again in the creation of fresh bricks or alternative refractory products. The recycling of used insulating fire bricks aids in the reduction of the need for fresh raw materials and the mitigation of waste. Nevertheless, it is crucial to acknowledge that not all recycling centers or facilities may accept insulating fire bricks. It is therefore advisable to verify with local recycling programs or specialized recycling companies that handle refractory materials.

- Q:Can insulating fire bricks be used in chimney construction?

- Indeed, insulating fire bricks have the capability to be utilized in the construction of chimneys. These bricks are specifically designed to possess a low thermal conductivity, which ultimately leads to their effectiveness in minimizing heat transfer. As a result, they prove themselves suitable for chimney construction as they aid in maintaining cooler chimney walls and preventing excessive heat from being transmitted to the surrounding structures. Moreover, apart from their lightweight nature, insulating fire bricks possess commendable insulation properties, thereby making their handling and installation in chimney construction a much simpler task. However, it is imperative to acknowledge that in order to comply with safety regulations and ensure proper chimney construction, it is crucial to utilize insulating fire bricks in conjunction with other fire-resistant materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulating Fire Brick IFB Straights for Ceramics Industries

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords