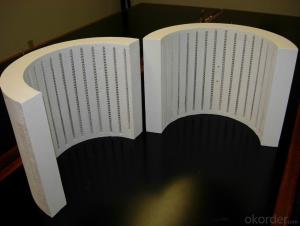

Insulating ceramic fiber board used for water heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SpecificationsCeramic Fiber Board for Combustion Chamber Insulation

1.Working Temp:1200C

2.Density:320kg/m3

3.Material:Alumina Silicate

Characteristic:

High stability

Low thermal conductivity

Low thermal capacity

Resistance to thermal shock

Good quality ceramic fiber board

Resistance to erosion

Easy to be processed and cut

High thickness precision and size precision

Exceptional ability to withstand flames and gas flows

Easy to install and convenient

Application

It has great anti-mechanical-destruction capacity, and can be applied as materials which require tenacity, self supporting ability,and thermal insulation ability. More specifically, it can be used as : thermal insulation lining and back lining in pusher kilns, ladle furnaces, bell-cover kilns,tunnel kilns, roller kilns, and aluminum melting kilns, and thermal treatment furnaces; high-temperature fire damper board and thermal insulation for kiln cars;

thermal insulation for various high-temperature industrial kilns and furnaces.

- Q:The characteristics of ceramic fiber paper

- Mifso-14 ceramic fiber paper gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced. Can be customized by users to produce sizes. Specifications: 10mm-- diameter, infinite product features: 1) continuous use temperature of up to 1000 degrees, a short time using temperature of 1260 degrees. 2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability. 3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes). 4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers. 5) non-toxic, harmless and odorless.

- Q:The product characteristics of ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life;With corrosion resistance, aluminum, zinc and other non-ferrous metal erosion capacity;

- Q:What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q:Brief introduction of ceramic fiber cloth

- General specifications of ceramic fiber cloth: 1.5mm--6mm, average width is 1m, which is divided into (nichrome wire reinforced stainless steel wire reinforced, glass fiber, ceramic fiber coating, ceramic fiber cloth with slag, sintered ceramic fiber cloth, ceramic fiber cloth fumigation) properties of ceramic fiber cloth:High temperature resistance, low thermal conductivity, thermal shock resistance and low heat capacity;Excellent high temperature insulation performance, long service life;With corrosion resistance, aluminum, zinc and other non-ferrous metal erosion capacity;It has good low temperature and high temperature strength;Non-toxic, harmless, no adverse effects on the environment;

- Q:At present, the field of ceramic fiber, what is the latest development of technology or products?

- Soluble ceramic fiber is a new product and biodegradable. Beijing Fei Pufu

- Q:What kind of material is ceramic fiber? What are the basic performance?

- (2) the density of Tao Xianzhan is below 200Kg/m3 (generally 160kg / m3), only light heat resistant lining L / 6 - 1/7.(3) the heat capacity is only 1 / 9 of light heat resistant lining and light fireclay bricks.(4) the ceramic fiber is stable in high temperature, the residual shrinkage rate is very small, and it needs no shrinkage or expansion joints, so it is easy to construct.(5) the coefficient of thermal conductivity is small. On the hot surface temperature of 600 degrees Celsius (the average temperature of 366 DEG C) when the orientation coefficient is 0.078W / (M. K); 900 (the average temperature is 551 DEG C) of O.096W / (m.k); 1100 (the average temperature is 678 DEG C) of 0.125W / (m.k), is about light fireclay bricks 1 / 8, for the light at 1 / 10 heat resistant lining.(6) sound insulation effect is good. The ceramic fiber coating can reduce the high-frequency noise with frequency less than 1000Hz, and also absorb some low-frequency noise.(7) it has a certain tensile strength.(8) good chemical stability.(9) good elasticity (78% at normal temperature), easy to transport and install.(10) it has better resistance to airflow erosion, and can withstand 30 - 50m/s airflow erosion.

- Q:How to choose the right ceramic fiber and aluminum silicate products?

- 3, according to the thickness of insulation to chooseThere are a lot of insulation thickness of furnace is fixed, the insulation thickness of conventional material is inappropriate, only according to the heat flow calculation formula to calculate the appropriate level of insulation material is the most scientific, the conventional case raised to two of the product can be registered.

- Q:What is the process of producing ceramic fiber mats?

- Specifications:Diameter 10mm-- infinityProduct features:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.

- Q:What brand of ceramic fiber products is best?

- Ceramic fiber, ceramic fiber, aluminum silicate fiber, its variety of products, the main products include ceramic fiber blanket (aluminum silicate blanket), ceramic fiber module (aluminum silicate module), ceramic fiber board (aluminum silicate), ceramic fiber paper (paper / aluminum silicate refractory fibre paper), ceramics (aluminum silicate fiber felt mat), ceramic fiber, ceramic fiber, ceramic fiber rope etc..The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q:Slag ball content of ceramic fiber material?

- 2800 ~ 3200kg/m the data of fand, right?Chasing the answerThis value is 2800 ~ 3200kg/m fand slag ball density, not ceramic fiber density

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulating ceramic fiber board used for water heater

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords