Injection molding machine LOG-500S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Condition: New

Type: Other

Style: Horizontal

Brand Name: LOG

Model Number: LOG-500S8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

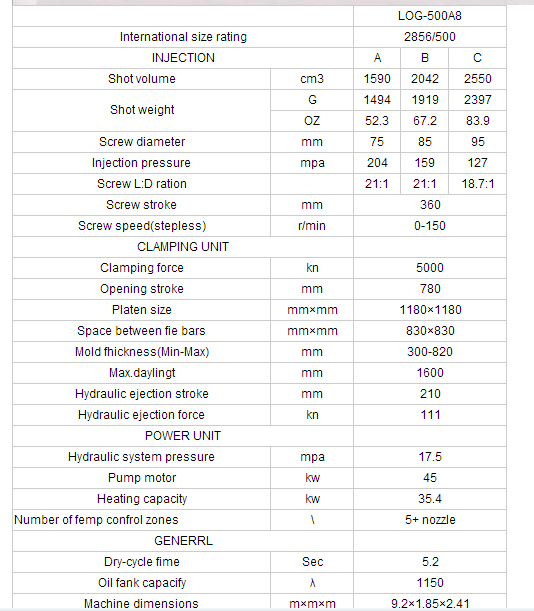

Injection Weight: 1494---2397G

Injection Rate: >100MM/S

Clamping Force: 5000KN

Opening Stroke: 820mm

Power(W): 37kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

- Q:RTBrother recently understand the injection mold related knowledge, about the forming cycle of this problem, I do not know whether this cycle can be estimated according to the relevant parameters, please advise!Forming cycle: the time between the previous product and the next product, including the time taken by the manipulator, and so on. I am for the new quotation, not too precise, but not too far away, trouble expert advice, small first, thank you very much!

- If a trial can be used to test out the stopwatch + wide release time, not the trial production of new software available for calculation, but the structure of a product cycle also depends on the size and thickness of the product, is complex and molding technology to all of these affect the product cycle, your statement is not very clear and it is difficult to give you a more accurate estimate of the cycle, experienced personnel can structure size, thickness, the product was estimated, and more reasonable!

- Q:What is the V-P conversion in injection molding machine?

- During injection molding, when the cavity is almost full, the movement of the screw is converted from flow rate control to pressure control.This transformation point is called the dwell switching control point, that is, the V-P switching point.The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products.

- Q:Haitian injection molding machine alarm, hydraulic insurance exception, what are the reasons?

- From what you have described, the problem is the hydraulic fluid, such as insufficient hydraulic fluid and impurities in the hydraulic fluid. Check, either add hydraulic oil, or replace the hydraulic oil.

- Q:Commissioning process of injection molding machine

- When we receive a set of moulds, we need to choose the machine according to the size of the mold, the clamping force and the size of the glue.Determine the type of machine before you enter the real tune. (the premise is that the machine is normal.)1. we first beer 10 beer water board plastic pieces (not go together -- about 95% of the full plastic glue), set the appropriate pressure to ensure that the actual pressure below the set (high pressure), starting from the highest rate of 99%, and then gradually reduce an amount equal to (10%) 10 plastic beer beer. - (constant pressure, rate of change of each separated by 10% to complete the 10 beer beer).2. record the filling time of each beer and the injection peak pressure.

- Q:For example, for nylon 6 GF30 material, some injection process information required to set the injection pressure is: 85-100MPa, the actual adjustment of the machine in our injection molding machine panel set the injection pressure is 65, then this number "65" unit is what?If the number of units is "bar", not with the data of some books conflict, please expert answer

- in fact, you can buy some books to look at the injection molding process, more contact with nature will be very clear.

- Q:Introduction to injection molding

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q:Eternal life injection molding machine screen blue screen what is the reason?

- DKM high speed injection molding machine can be a reboot, complete all reset

- Q:transparent parts inside the bubble, how to solve this problem, non -, what is the cause?

- It is a bit complicated, did not see the kind, generally there are two possible reasons: one is that there may be more humid caused the raw materials, WIP bubbles appear relatively thick, dense and bubble like you; this can be ruled out, there is a lack of a little exhaust design mold. Specific reasons to see objects in order to determine! I wonder if I can help you.

- Q:What is the injection molding machine back pressure, back pressure role is what?

- Adjustment of back pressureThe adjustment of the injection back pressure shall be determined according to the raw material performance, drying conditions, product structure and quality, and the back pressure should be adjusted at 3-15kg/cm 3. When the surface of the product has little Qihua, mixed color, shrink and product size and weight changes, may be appropriate to increase the back pressure. When the nozzle leakage glue, salivation, Melt Overheating product decomposition, discoloration and feeding back too slow may be considered appropriate to reduce the back pressure.Back pressure is one of the important parameters to control melt quality and product quality in injection molding process. Proper back pressure plays an important role in improving product quality, and can not be ignored!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-500S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords