Injection Molding Machine LOG-500A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Preform Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG-500A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 1919g

Injection Rate: <SPAN class=attr-value title=459cm3/s style="BORDER-RIGHT: 0px; PADDING-RIGHT: 0px; BORDER-TOP: 0px; PADDING-LEFT: 0px; PADDING-BOTTOM: 0px; MARGIN: 0px; VERTICAL-ALIGN: baseline; BORDER-LEFT: 0px; PADDING-TOP: 0px; BORDER-BOTTOM: 0px; FONT-FAMILY: inherit; WORD-WRAP: break-word; font-stretch: inherit">459cm3/s

Clamping Force: 5000KN

Opening Stroke: 780mm

After-sales Service Provided: Overseas third-party support available

energy saving: oil saving

| Description | Unit | LOG-500A8 | ||

| international recognized models | 3240/500 | |||

| Injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 1590 | 2040 | 2550 |

| Shot volume | g | 1494 | 1919 | 2397 |

| Oz | 52.3 | 67.2 | 83.9 | |

| Screw diameter | mm | 75 | 85 | 95 |

| Injection diameter | mpa | 204 | 159 | 127 |

| Screw L:D ratio | 23.8:1 | 21:01 | 18.7:1 | |

| Scerw steoke | mm | 360 | ||

| Screw rotate speed | r/min | 0-150 | ||

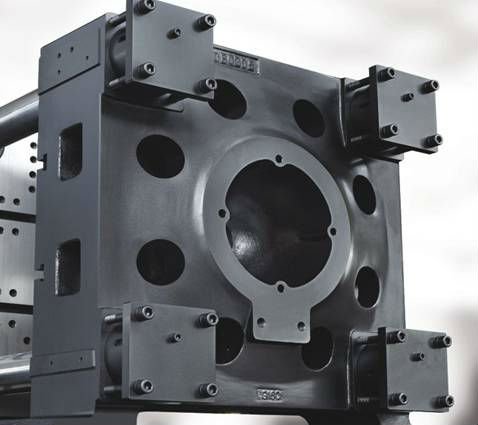

| CLAMPING UNIT | ||||

| Clamping force | kN | 5000 | ||

| Opening stroke | mm | 820 | ||

| Platen size | mm*mm | 1180*1180 | ||

| Space between tie bars | mm*mm | 830*830 | ||

| Maldthickness | mm | 300-820 | ||

| Platen Mix stroke | mm | 1600 | ||

| Ejection stroke | mm | 210 | ||

| Ejcetion force | kN | 111 | ||

| Power/Elcetric Heating | ||||

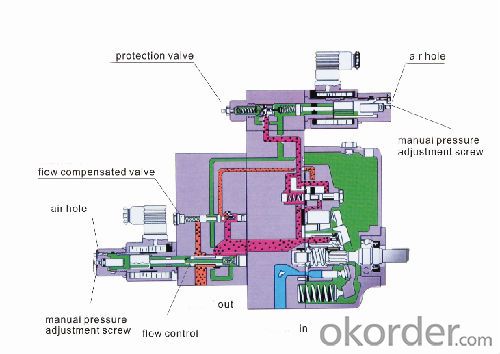

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7+29 | ||

| Heating power | kw | 42.5 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5.2 | ||

| Tank volume | L | 1150 | ||

| Machine dimesions | m*m*m | 9.2*1.85*2.41 | ||

| Weight of machine | kg | 22000 | ||

Packaging & Delivery

| Packaging Details: | one machine in a 40GP container |

|---|---|

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

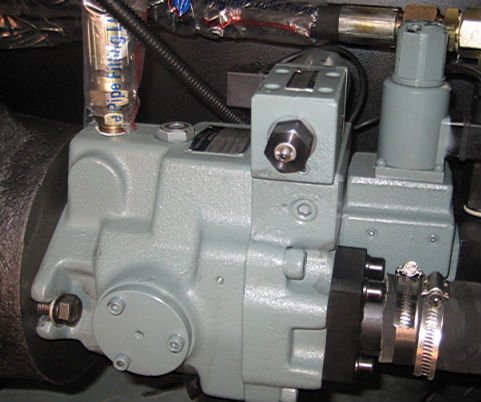

high response 2. high precise 3. oil saving 4. water saving 5. long working life

- Q:How many tons is the injection machine of 12 Ann?

- In general, the injection molding machine of various specifications, there are several specifications of the screw, buyers can choose different screw size according to their uses, the screw diameter may be selected smaller, and the groove depth is also different with a shallow depth. For example, the production of PVC, will be shallow groove.Ann and T conversion is quite troublesome, here only give some common types of control: injection molding machine 4 (50T) 8 sets of injection molding machine 6 (120T) 8 sets of injection molding machine 8 (140T) 5 sets of injection molding machine 12 (160T) 5 sets of injection molding machine 16 (180T) 3 sets of injection molding machine 18 (200T) 4 sets of injection molding machine 24 (250T).

- Q:injection molding machine is used, every day is 20000G 10000G 7000G of 6000G 4000G 2000G 1000G 560G 210G why the type of injection machine to overcome the number of markers. For example, 20000G injection molding machine can be injected products of the quality of the largest and minimum number of kilograms, thank you

- Injection molding machine models are generally defined in two ways: first, the injection volume (grams); two, clamping force.

- Q:Production calculation... 60 / 60 seconds * / / 25 x 32 / sec / mold die =1 * 12 hours per hour yield = 12 small classInjection molding machine... Production calculation... 60 / 60 seconds * / / 25 / 32 / sec * die die =1 output * 12 hours = 12 hour shifts production 55075But I don't get enough output every day... Can only do 49501 pieces, ask 49501 pieces to take several hours to be able to do... How much extra time do I have to add to the production?... Urgent urgent... Can not take a day except what count how much time yield......

- 1. are you fully automated? If it's fully automated, then you'll be able to record each exception from minutes to minutes, so you know your abnormal hours. If it is semi-automatic production, it depends on the boot staff, the door is not stable, this can be seen inside the injection molding machine.2. can not take a day except what count how much time yield......49501 / 1 hour yield = production hoursPS: personal experience, or to offer internal injection tube reported capacity of up to 23 hours of production capacity, 24h two classes, each class for half an hour maintenance and machine maintenance time is a must (of course sometimes less capacity of the interface). I used to be in accordance with 22h reported capacity, otherwise delivery can not come out, you hang up, give yourself more room.

- Q:How does the injection machine prevent the product from sputtering to the machine? As for the question, how can I solve it perfectly?

- It's time to slow down. Is it a launch rocket? It's too vigorous. Not really. Just use a cardboard file

- Q:Injection machine profile size

- The aperture of the nozzle (injection hole) is generally 2.2-2.5mm.

- Q:What does injection pressure mean?

- Three, back pressure is too low, prone to the following problems1, the back pressure is too low, screw back into the barrel too fast, the front end of the melt density (Jiao Songsan), into the air. 2, will lead to poor quality of plastic, the amount of plastic spray instability, product weight, product size changes. 3, the product surface will appear shrinkage, gas flower, cold material lines, uneven luster and other undesirable phenomena. 4, the product prone to bubbles, the product surrounding and bone position, easy to walk dissatisfied glue.Four, high back pressure, prone to the following problemsMelt pressure is 1, the front end of the barrel is too high, high temperature material, decrease viscosity, melt in the screw slot of the upstream and the barrel and screw clearance leakage flow rate increases, will reduce the plasticizing efficiency (feed plasticizing unit time).2, for the poor thermal stability of plastic (such as PVC, POM etc.) or coloring, thermal decomposition caused by melt temperature and heating time of growth in the barrel, increases the degree of discoloration or coloring, product surface color / gloss variation.3, back pressure is too high, screw back slow, pre plastic back material time is long, will increase cycle time, lead to production efficiency decline.4, high pressure, high melt pressure, injection nozzle after prone to melt salivation phenomenon, next injection, cold flow feeding nozzle will plug the outlet or product in cold spot.5, in the process of beer molding, often due to excessive back pressure, nozzle leakage phenomenon, waste of raw materials, and lead to near the nozzle heat ring burned.6. The mechanical wear of the preform and screw barrel increases.

- Q:Please tell me the reason for choosing this tonnageFor example, an injection molding machine, water flow of 4 tons per hour, then 4 units on the election of 20T cooling tower is not enough? 20T's cooling water flow is about 18 cubic meters per hour

- In general we 160T mold, pipe size of 16MM-20MM in diameter, but in general we pump flow rate Straw at 2 m / S (injection cooling water is recycled, water pump Straw flow is the decision point need air conditioning cooling tower), so we can assume that the size of pipe diameter is 20MM, the water flow rate of 2 meters so every hour per second; each injection molding machine needs the amount of water:PI (0.01 meters) * (0.01 meters) *2 M / s *3600 s =2.26 cubic metersYou do this, and here you should be clear! In addition, individuals feel that there is still need to consider whether the subsequent expansion of production, that is, increase the number of injection molding machine, so personally feel that the need to reserve space as well!

- Q:How about the four column balance of injection molding machine?

- Four column balance correction method for injection molding machine:With the clamping force tester, the force of the four tie rods is adjusted.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type.

- Q:The proportion of each kind of introduction? Molding shrinkage? Molding temperature? Drying conditions? Overall performance? Mainly for use. I sell plastic parts and I want to make a wall calendar.

- you still go to find a professional book, check the good, this to make a mistake, lost your face.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-500A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords