Injection molding machine LOG-320S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG-320S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 1120g |

| Injection Rate: | >362cm3/s |

| Clamping Force: | 3200KN | Opening Stroke: | 615mm | ||

| Power(W): | 31kw | Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

| blue: | yellow |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 days |

Product Description

Product performance and advantages:

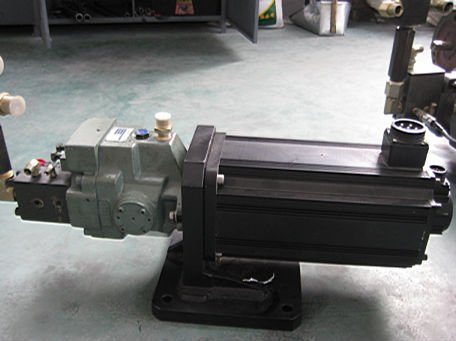

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-320S8 Technical parameters

Description | Unit | LOG-320S8 | ||

international recognized models | 1870/320 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 1062 | 1231 | 1414 |

Shot volume | g | 966 | 1120 | 1286 |

Oz | 33.7 | 39.2 | 44.9 | |

Screw diameter | mm | 65 | 70 | 75 |

Injection diameter | mpa | 175 | 152 | 133 |

Screw L:D ratio | 22.6:1 | 21:1 | 19.6:1 | |

Scerw steoke | mm | 320 | ||

Screw rotate speed | r/min | 0-150 | ||

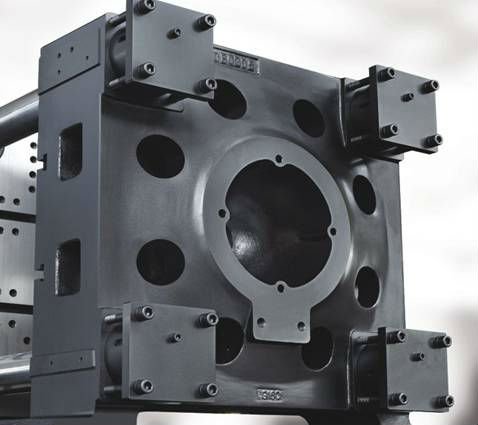

CLAMPING UNIT | ||||

Clamping force | kN | 3200 | ||

Opening stroke | mm | 615 | ||

Platen size | mm*mm | 945*945 | ||

Space between tie bars | mm*mm | 660*660 | ||

Maldthickness | mm | 250-670 | ||

Platen Mix stroke | mm | 1285 | ||

Ejection stroke | mm | 160 | ||

Ejcetion force | kN | 77 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 31 | ||

Heating power | kw | 25.3 | ||

Number of temp.conteol | 5+nozzle | |||

Other | ||||

Cycle time | sec | 5.0 | ||

Tank volume | L | 500 | ||

Machine dimesions | m*m*m | 6.8*1.63*2.25 | ||

Weight of machine | kg | 13000 | ||

- Q:Injection molding machine products shrink, how to solve?

- Injection pressure, holding pressure, speed, back pressure, temperature, glue content, inlet and die temperature

- Q:What are the types of injection molding machines?

- As the structure and types of injection molding products are relatively large, the injection molding machine used for molding injection products is also more.

- Q:What is low voltage protection (injection molding machine)?

- Low pressure protection is to prevent the mold cavity foreign body, avoid too much pressure, damage to the moldUsually by the low pressure clamping mode, time, stroke, pressure, three conditions to coordinateFor example, the low pressure lock mode time out, the mold will automatically open and stop alarm, play a role in protecting the mold

- Q:Name of China's top ten famous brand injection molding machines

- Sheng Yue, Chen De, Haitian, Shanghai Guangsu, Huada, Glenn, Borch, grand, ACE, Chung East, too, Haitai, energy, Lima, DMX, Acer too, and wide, Hongli, starfish

- Q:What do you mean by the "starting position and time" of the injection molding machine?.

- Here's some advice to see if it will help you. Let's first understand the meaning of pressure and pressure. The injection pressure is the pressure applied to the material in the process of advancing. Keep the pressure, that is, after the glue is finished, continue to maintain a pressure. The rubber here is in principle not a force given by the feed. Thus, the position of the dwell pressure is determined by the fact that you are no longer positioned. The effect of holding pressure is to continue to give a force to prevent the return of the glue, so that the product is fuller. The position and time of holding pressure, the design of the machine is usually based on the location, and has not reached the set position of the pressure setting, it starts with the time after the completion of the injection glue.

- Q:Plastic injection molding machine barrel diameter is how many centimeters or millimeters?

- 1 metric thread diameter is in millimeters, such as 6, 8, 10, 12, 18, 20 mm, etc., the pitch is in millimeters, such as 0.5,0.75,1,1.5,2,3, and so on

- Q:Notice of injection moulding machine

- Injection molding machine temperature rise is too high, five major hazards: the machine produces thermal deformation, oil viscosity decreases, rubber seals deformation, accelerate oil oxidation deterioration, but also make the air component pressure reduction.One of the hazards: causes the machine to produce thermal deformationIn the hydraulic component, the moving parts with different thermal expansion coefficients are jammed because of the small clearance between them, which results in malfunction and influences the drive accuracy of the hydraulic system, resulting in the poor quality of the parts.Hazard two: reduce the viscosity of the oilThe high temperature rise of the injection molding machine will lead to lower viscosity of the oil and leakage increase. The volume efficiency of the pump and the efficiency of the whole system will be significantly reduced. As the viscosity of the oil decreases, the oil film of the moving parts, such as the slide valve, is thinned and cut, and the frictional resistance increases, leading to increased wear.Hazard three: deform rubber sealsThe temperature rise of the injection molding machine is too high, it will deform the rubber seal, accelerate the aging failure, reduce the sealing performance and service life, and cause leakage.Four of the hazards: to accelerate the oxidation of oilThe temperature rise of the injection molding machine is too high, it will accelerate the oxidation of the oil, precipitate the asphalt material, and reduce the service life of the hydraulic oil. The precipitate blocks the damping orifice and the slit valve opening, causing the pressure valve to stop and cannot move, and the metal pipe lengthens and bends, and even breaks.

- Q:What does "120T 140T" mean in an injection machine?

- A, an abbreviation for ounce, is a unit used by the Hongkong industry to distinguish between injection molding machines. In this way, in the domestic commonly known as "T" (ton), "12" equivalent to "160T", the screw diameter of about 32 mm. In general, the injection molding machine of various specifications, there are several specifications of the screw, buyers can choose different screw size according to their uses, the screw diameter may be selected smaller, and the groove depth is also different with a shallow depth. For example, the production of PVC, will be shallow groove.Ann and T conversion is quite troublesome, here only give some common types of control: injection molding machine 4 (50T) 8 sets of injection molding machine 6 (120T) 8 sets of injection molding machine 8 (140T) 5 sets of injection molding machine 12 (160T) 5 sets of injection molding machine 16 (180T) 3 sets of injection molding machine 18 (200T) 4 sets of injection molding machine 24 (250T)

- Q:When the injection machine is ejected, does the screw screw rotate?

- The one behind the battery will turnAskIs the hopper out of place?What is a fort, not a shooting station?Chasing the answer

- Q:transparent parts inside the bubble, how to solve this problem, non -, what is the cause?

- It is a bit complicated, did not see the kind, generally there are two possible reasons: one is that there may be more humid caused the raw materials, WIP bubbles appear relatively thick, dense and bubble like you; this can be ruled out, there is a lack of a little exhaust design mold. Specific reasons to see objects in order to determine! I wonder if I can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-320S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords