injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG 250S8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 625

Clamping Force: 2500kn

Opening Stroke: 520mm

Power(W): 29kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

|---|---|

| Delivery Detail: | 30 Days |

Product performance and advantages:

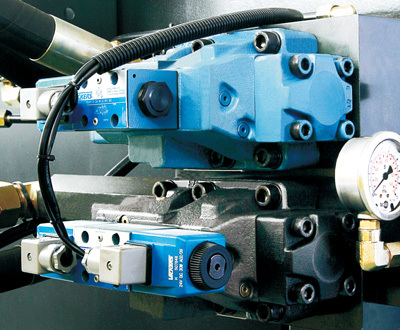

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-250S8 Technical parameters

Description | Unit | LOG-250S8 | ||

international recognized models | 1140/250 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 510 | 687 | 863 |

Shot volume | g | 464 | 625 | 785 |

Oz | 16.2 | 21.8 | 27.4 | |

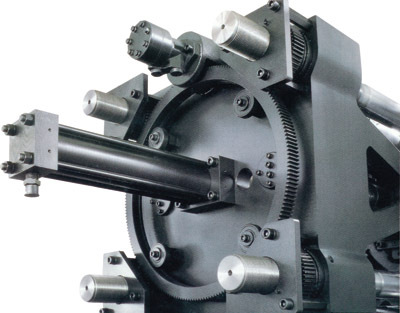

Screw diameter | mm | 50 | 58 | 65 |

Injection diameter | mpa | 224 | 166 | 132 |

Screw L:D ratio | 24:1 | 21:1 | 18.7:1 | |

Scerw steoke | mm | 260 | ||

Screw rotate speed | r/min | 0-180 | ||

CLAMPING UNIT | ||||

Clamping force | kN | 2500 | ||

Opening stroke | mm | 520 | ||

Platen size | mm*mm | 820*790 | ||

Space between tie bars | mm*mm | 560*530 | ||

Maldthickness | mm | 200-580 | ||

Platen Mix stroke | mm | 1100 | ||

Ejection stroke | mm | 150 | ||

Ejcetion force | kN | 67 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29 | ||

Heating power | kw | 16 | ||

Number of temp.conteol | 4+nozzle | |||

Other | ||||

Cycle time | sec | 4.8 | ||

Tank volume | L | 380 | ||

Machine dimesions | m*m*m | 6.2*1.46*2.15 | ||

Weight of machine | kg | 8000 | ||

- Q:What's the pressure and speed of melt press in injection molding machine?

- Sol pressure: commonly known as back pressure, refers to the back of the screw when the pressure carried. In the process of melting and plasticizing of plastics, the melt moves to the front of the cylinder (metering chamber), and more and more, gradually forming a pressure to push the screw back. In order to prevent the screw from backing too fast and to ensure uniform compaction of the melt, it is necessary to provide an opposite direction of pressure to the screw, which is the reverse pressure that prevents the screw from retreating. Back pressure is also known as plasticizing pressure, and its control is achieved by adjusting the oil return valve of the injection cylinder. Pre injection plasticizing screw injection molding machine is equipped with the rear end of the oil cylinder back pressure valve, regulating screw back when the injection cylinder oil cylinder speed, to maintain a certain pressure; shift speed screw motor after (resistance) is composed of AC servo valve control.Sol speed: injection molding machine in the gum into the screw drive, the screw moving speed, that is, the plastic into the screw speed.

- Q:Injection molding machine, blister machine, blow molding machine, what is the fundamental difference?

- Injection molding machine - a machine that produces plastic products by filling the mold with pressure.

- Q:What is the problem of Shanghai plastic injection molding machine in the die closing process?

- Solenoid valve installed wrong, or out of the oil path is simple along the road, and the solenoid valve is connected to reverse.

- Q:How to calculate the clamping force of injection molding machine according to the product

- Clamping force x09F>=k*P*AF= actual clamping force (KN) x091KG = 9.8NP = cavity mean pressure (Mpa) x091MPa = 9.8KGThe projected area (cubic centimeter) of the A= product on the parting surface x09K = safety factor, usually take 1.1-1.6.x09Injection pressure, x09, injection pressure, =1.5* internal pressureGrade x09 internal mold pressure (kg/cm2)Precision products x09550-700Common product x09350-500Liepin x09250-300

- Q:when the temperature rising in the exit but this is what the normal temperature increase of more than 20 degrees

- 1, your machine back pressure regulation is too large; 2, screw idle or slip, cause melt time longer, friction produce heat; 3, setting temperature is too low, melt resistance is too large, friction produce heat;

- Q:Introduction of injection molding machine

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting material using plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q:General injection molding machine agents need what conditions?

- See what brand you agent, big manufacturers brand trouble

- Q:How is the screw speed of injection molding machine adjusted? Who knows very well?.

- Injection molding machine screw speed, first, adjust the injection molding machine pre molding pressure and flow, and then adjust the back pressure

- Q:How many solenoid valves are there on the injection molding machine?

- Solenoid valve is used to control the automation of the fluid basic components, belonging to the actuator; not limited to hydraulic, pneumatic. Solenoid valve used to control the direction of hydraulic flow, the factory's mechanical devices are generally controlled by hydraulic steel, so it will use the solenoid valve.

- Q:How much is a new injection molding machine, mainly mobile phone shell?

- Look at the brand, 100T models, domestic cheap, prices do not know

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords