Injection Molding Machine LOG-250A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG250-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 464-785g

Clamping Force: 2500 kn

Opening Stroke: 520mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

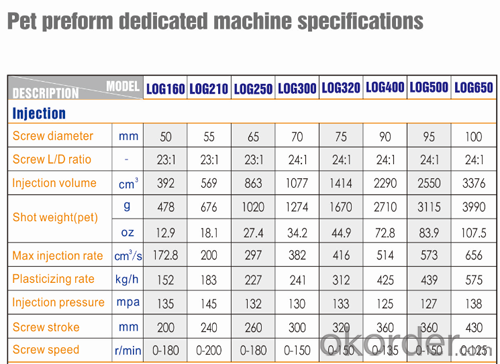

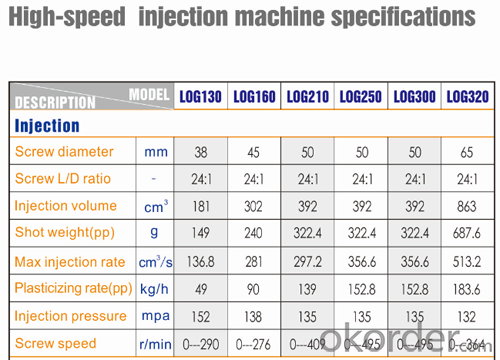

Screw Diameter: 50-58-65

Machine weight: 8 T

Material: Stainless Steel

Screw speed: 0-180 r/min

Function: Plastic Injection Molding Machinery

Space between Tie Bar: 560X530mm

Name: horizontal Injection Molding Machine

Ejector stroke: 150mm

Injection pressure: 132-224 mpa

Packaging Details: 20 GPcabinet

Delivery Detail: In one week after get payment

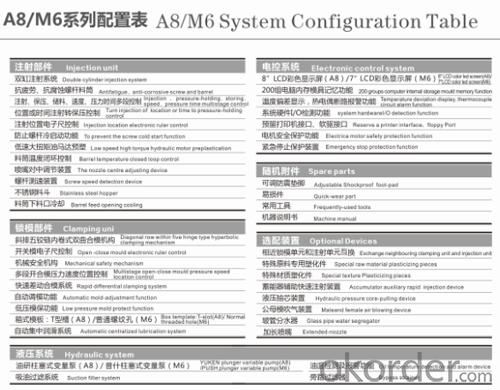

| LOG-250A8 | ||||

| International size rating | 1140/250 | |||

| INJECTION | A | B | C | |

| Shot volume | cm3 | 510 | 687 | 863 |

| Shot weight | G | 464 | 625 | 785 |

| OZ | 16.2 | 21.8 | 27.4 | |

| Screw diameter | mm | 50 | 58 | 65 |

| Injection pressure | mpa | 224 | 166 | 132 |

| Screw L:D ration | 21:01 | 21:01 | 18:07:01 | |

| Screw stroke | mm | 260 | ||

| Screw speed(stepless) | r/min | 0-180 | ||

| CLAMPING UNIT | ||||

| Clamping force | kn | 2500 | ||

| Opening stroke | mm | 520 | ||

| Platen size | mm×mm | 820×790 | ||

| Space between fie bars | mm×mm | 560×530 | ||

| Mold fhickness(Min-Max) | mm | 200-580 | ||

| Max.daylingt | mm | 1100 | ||

| Hydraulic ejection stroke | mm | 150 | ||

| Hydraulic ejection force | kn | 67 | ||

| POWER UNIT | ||||

| Hydraulic system pressure | mpa | 17.5 | ||

| Pump motor | kw | 22 | ||

| Heating capacity | kw | 16 | ||

| Number of femp confrol zones | \ | 5+ nozzle | ||

| GENERRL | ||||

| Dry-cycle fime | Sec | 4.8 | ||

| Oil fank capacify | λ | 380 | ||

| Machine dimensions | m×m×m | 6.2×1.6×2.15 | ||

| Machine weight | kg | 8000 | ||

product 1

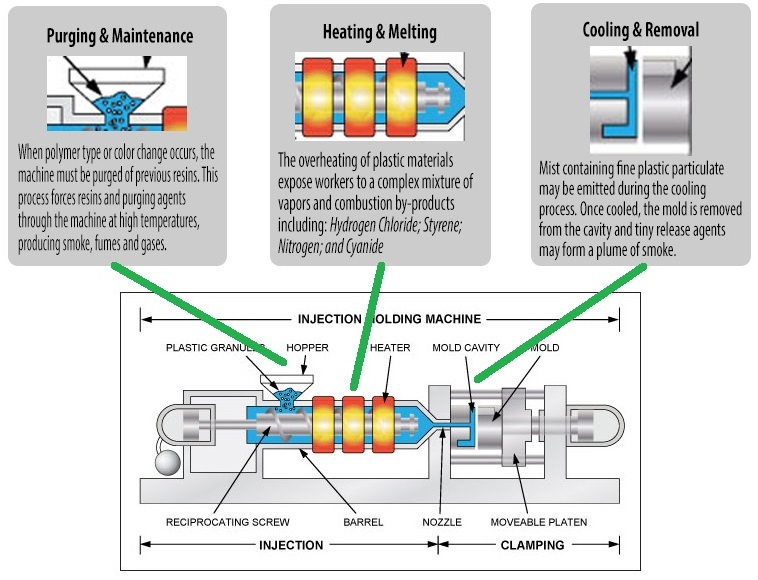

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

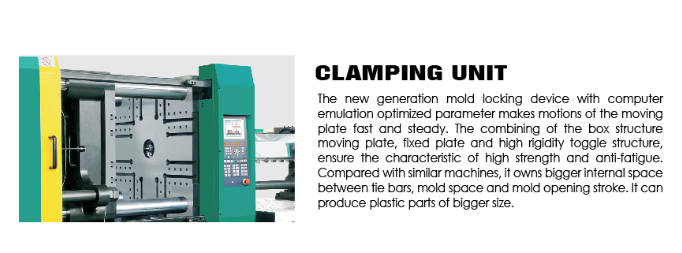

1 The mould closing unit

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate fast and steady .When combining the box type moving plate ,fixed plate and high rigidity toggle structure ,the characteristic of high strength and anti-fatigue is secured. As compared with similar machine , it owns bigger internal spur between tie bars ,mold space and mold opening storke and may process plastic product of bigger size.

2 Computer controller

professional injection molding machine controller with software abd hardware of industrial standard is convenient to expansion and revision of performance. Adopting double CPU control makes high speed.

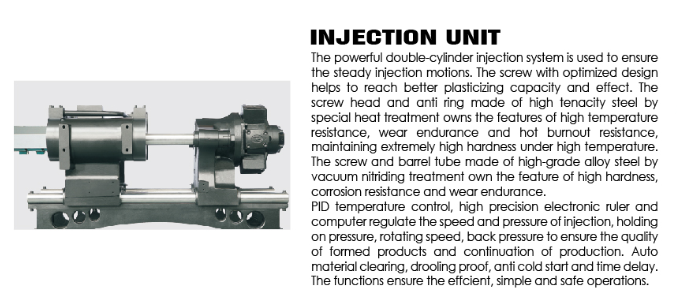

Variable Displacement Pump

1 Low Noise

Reasonable hydraulic control structure design, high integration and unipue processing in noise reduction helps machine run smoothly.

2 Oil-saving

The low oil temperature prolongs the srevice life of sealing elements .Oil cleaning equipment can filter the grease rapidly and effectively to ensure the srevice life of hydradulic elements.

3 Quick Response

The imported directly and high-response variable displacement pump achieves larger amount of emission by 20% to 25% than fixed pump driven the same motor.

4High Stability

30% to 70% energy saving compared with fixed pump under the equipment volume of work .

5 Water Saving

With no overflow and heating from variable displacement with fixed pump, 50%-75% water can be saved compared with fixed pump. Oil cleaning equipment is designed to improve the service life of hydraulic oil for 5 year.

- Q:What's the pressure and speed of melt press in injection molding machine?

- Sol pressure: commonly known as back pressure, refers to the back of the screw when the pressure carried. In the process of melting and plasticizing of plastics, the melt moves to the front of the cylinder (metering chamber), and more and more, gradually forming a pressure to push the screw back. In order to prevent the screw from backing too fast and to ensure uniform compaction of the melt, it is necessary to provide an opposite direction of pressure to the screw, which is the reverse pressure that prevents the screw from retreating. Back pressure is also known as plasticizing pressure, and its control is achieved by adjusting the oil return valve of the injection cylinder. Pre injection plasticizing screw injection molding machine is equipped with the rear end of the oil cylinder back pressure valve, regulating screw back when the injection cylinder oil cylinder speed, to maintain a certain pressure; shift speed screw motor after (resistance) is composed of AC servo valve control.Sol speed: injection molding machine in the gum into the screw drive, the screw moving speed, that is, the plastic into the screw speed.

- Q:Every time the adhesive is stable, the glue is basically stable, but about 100 of the 2-3 die will not be in place, for example, the 50MM will stop

- The injection time is not enough, the pressure of 50mm injection is not enough

- Q:Domestic injection molding machine which brands are better?

- Haitian, Chun, etc. are good.High exposure... Shock bear, Iraq's secret, Bo Chuang, Donghua

- Q:What are the features of servo motors for injection molding machines?

- 1, energy saving2 、 quick response and high production efficiency,3 、 pressure stability precision4, high repeatability, saving material5 、 low temperature rise of oil temperature6, low noise

- Q:What plastic injection machines and materials are needed for making plastic waste shovels?

- Should use horizontal injection molding machineThere are several kinds. Pc.pom.pp.pa66+30%, see how you choose it.

- Q:What kind of metal material is the nozzle head of injection molding machine?

- Screw is an important part of injection molding machine. Its function is to transport, compact, melt, stir and press the plastic. All this is done by rotating the screw in the barrel. When the screw rotates, the plastic will cause friction and movement between the inner wall of the cylinder, the bottom of the screw, the bottom of the screw, the advancing surface of the screw and the plastic and plastic.Often used to produce screw material:1, 38CrMoAla2, SACM6453, 42CrMo4, 9Cr18MoV5, SKD616, tungsten carbide alloy, tungsten carbide nickel based alloy7 、 fully hardened powder alloy (Quan Hejin)8, high temperature alloy

- Q:What is the injection molding machine?

- An injection molding machine is a mechanical device that fills a plastic into plastic!!

- Q:Now I know a product of the material cost unit (single weight + nozzle), but how to calculate artificial + factory rent + machine wear + Plus transport + packing material, seek heroes pointing. emergency

- The cost of plastic parts is related to many factors, but mainly with the following points:1. Cost of raw material --- this cost is relatively good calculation, ask a raw material supplier how much 1 kg, the weight of the product multiplied by 3% of the loss multiplied by the raw material price, you can get the cost of raw materials;2.. This machine cost about plastic factory, what is the cost of processing per hour of different injection molding machine? Suppose the 1 ton injection molding machine costs 60 yuan / hour per hour, then the processing cost is 1 yuan per minute. At this time, we should calculate the cost of the 100 ton machineWhat is the injection period of plastic parts and how many opening holes are in the mold? Suppose you want to evaluate the injection period of the plastic partsFor 30 seconds, then 1 minutes can shoot 60 seconds divided by 30 equals two, said 1 minutes can shoot the second mock exam products, in addition to a two point that mold, then plastic machine processing costs 1 yuan by 1 minutes and then divided by the modulus of mouldThe number of holes to get the final machine processing costs, that is, 1 yuan divided by 2 modules, and then divided by 2 points, and finally wait until 0.25 yuan /3., two additional costsThe two processing costs include painting / screen printing / plating etc. These can be referred to their respective processing plants4. packing chargesAccording to the size and volume of the plastic parts, we can draw the packing carton / packing bag and so on;5. transportation costAccording to the location of delivery and how much container freight can be loaded, divided by the total number of trucks to be shipped per PCCost;6. other expenses;Since the above costs do not include the costs of indirect personnel and their associated personnel, there is also a need to add some costs to each plant;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-250A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords