Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A8 CONFIGURATIONS

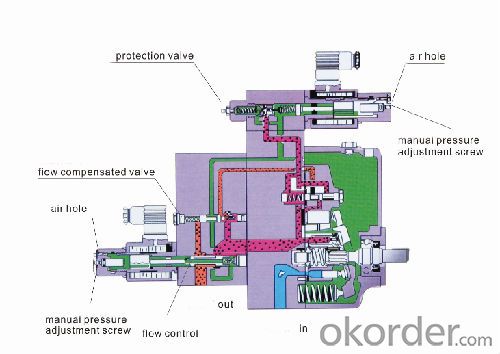

PROPORTIONAL VARIABLE PUMP YUKEN

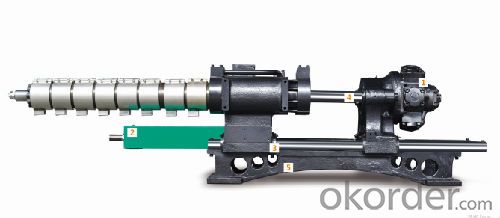

OIL MOTOR INTERMOT

DIRECTION VALVE VICKERS

COMPUTER MIRLE 9118

AC CONTACTOR SCHNEIDER

ELECTRONIC RULER NOVO

LUBICATION PUMP HERG

Quick Details

Condition: New

Type: Other

Style: Horizontal

Brand Name: LOG

Model Number: LOG-160A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 260---368G

Clamping Force: 1600KN

Opening Stroke: 430MM

Power(W): 15kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

LOG160-A8 energy-saving plastic injection moulding machine

| Description | Unit | LOG-160A8 | ||

| international recognized models | 525/160 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 277 | 318 | 392 |

| Shot volume | g | 260 | 298 | 368 |

| Oz | 9.1 | 10.5 | 12.9 | |

| Screw diameter | mm | 42 | 45 | 50 |

| Injection diameter | mpa | 190 | 166 | 135 |

| Screw L:D ratio | 21.4:1 | 20:01 | 18:01 | |

| Scerw steoke | mm | 200 | ||

| Screw rotate speed | r/min | 0-200 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 1600 | ||

| Opening stroke | mm | 430 | ||

| Platen size | mm*mm | 680*680 | ||

| Space between tie bars | mm*mm | 460*460 | ||

| Maldthickness | mm | 180-500 | ||

| Platen Mix stroke | mm | 930 | ||

| Ejection stroke | mm | 140 | ||

| Ejcetion force | kN | 50 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7 | ||

| Heating power | kw | 12.6 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 2 | ||

| Tank volume | L | 210 | ||

| Machine dimesions | m*m*m | 4.95*1.25*2.0 | ||

| Weight of machine | kg | 5100 | ||

- Q:What does injection mean?

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q:How to check the mold opening stroke of injection molding machine

- 1. the maximum opening stroke of injection molding machine has nothing to do with the die thicknessMainly refers to the clamping mechanism for injection molding machine with hydraulic machinery, such as XS-Z-30, XS-Z-60, XS-ZY-125, XS-ZY-350, XS-ZY-500, XS-ZY-1000 and G54-S200/400 type injection molding machine, the mold opening stroke by the connecting rod mechanism (or clamping cylinder) determines the maximum stroke, irrespective of the thickness of the mold.For injection mold with single parting surface:Smax = H1+H2 + mm (5 ~ 10)For injection mold with double parting surface:Smax = H1 +H2 + +a (5 ~ 10) mmType: Smax injection molding machine maximum mold opening stroke (mm);H1 plastic parts (mm, H1) launched a distance - like mold core is equal to the height, but for the plastic parts of the inner surface is stepped, sometimes do not have to launch the full height core can remove the plastic parts, then H1 can be determined according to specific circumstances, in order to successfully remove the plastic parts;H2 a piece of plastic height, including the height of the castable (mm) of the gating system that is connected to the plastic part.A the distance between the fixed die seat plate and the runner plate required by the casting system to remove the condensate (mm).

- Q:What is the fluctuation of the screw speed of injection molding machine?

- Screw speed fluctuation of injection molding machineFor isothermal Newton fluid, the volumetric flow rate (Q) of the extruder is proportional to the isothermal Newton flow, and the extrusion flow rate is proportional to the screw speed. This relationship has important guiding significance for production practice. It shows that the output of extruder can be greatly improved by increasing the rotational speed. The history of the development of single screw extrusion machine also increases the speed of ladle is one important way to improve the production capacity of a single machine and the actual extrusion process flow rate and screw speed q is not completely linear, this is mainly because we are in these formulas of the melt viscosity, outlet pressure, melt rheological properties were simplified processing.

- Q:What is TMC injection molding machine?

- TMC is the abbreviation of Jiangmen excellent Electromechanical Industry Co., ltd..Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type.

- Q:What are the features of servo motors for injection molding machines?

- 1, energy saving2 、 quick response and high production efficiency,3 、 pressure stability precision4, high repeatability, saving material5 、 low temperature rise of oil temperature6, low noise

- Q:How about overheating of injection molding machine drives?

- Ask for advice! The factory has the secret MA1600 of the Taiwan Strait, the drive is over temperature, the electric heating is not hot, the motor contactor does not suck

- Q:What is the percentage of nozzles in injection molding machines?

- According to the 100 degree metaphor, the setting 50% is 50 degrees

- Q:Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.

- Q:Why should the central feed system be used in the injection molding workshop?

- The advantage of using the central feed system in the injection molding workshop is that:1. save energy2. save labor costs3. improve the company's overall image4. keep the factory environment clean and tidy5., centralized management of raw materials to avoid waste of raw materials and pollution6., can isolate the main transmission, reduce noise pollution"Dongguan niasi" the central feeding system adopts the vacuum conveying mode, through the pipeline system will focus on plastic raw materials from the storage tank is transferred to the central dehumidification system will then transport the raw material after drying to each injection molding machine. "Dongguan niasi" the central feeding system adopts "design a machine of a pipe", to ensure the whole system of raw materials for air transport, to prevent the resurgence of the raw material after drying dehumidifying. At the same time, the pipeline can be cleaned up after each conveying cycle to ensure that there is no residual granular material in the pipeline. The material performance of the injection molding machine is guaranteed to be consistent while avoiding the resurgence of the raw material. Under the vacuum negative pressure, the dust in the raw material will be filtered out through the dust filtration system, which will help to improve the quality of the molding products.Please refer to the resources below for a detailed example of the central feeding system!!!

- Q:What measures can be taken to shorten the molding process cycle of injection molding machines?

- Reduce the mold temperature, reduce the heating temperature of cylinder, increase the speed of die closing and shorten the cooling and holding time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords