Industrial Silicon Producing Graphite Electrodes UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

1.Diameter: 200 to 700mm

2.Length: 1600 to 2400mm

3.Nipple:3-4TPI

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

1. Grade: RP, HP, UHP, SHP, RPI

2. Diameter: 200 to 700mm at your choice.

3. Length: 1600 to 2400mm at your choice.

4. Nipple: 3-4 TPI

5. Fine mechanical strength and machining quality, low specific resistance, high temperature and oxidation resistance

6. Low price and timely delivery.

Feature

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

Grades: RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

UHP

Physical and chemical index

Item | Unit | Nominal Diameter(mm) | |||

YB/T4088-2000 | Typical Values | ||||

Industry Standard | |||||

300-400 | 450-550 | 350-550 | |||

Resistance | Electrode | ohm | ≤6.2 | ≤6.5 | 4.6-6.2 |

Nipple | ≤5.5 | ≤5.5 | 3.5-4.5 | ||

Bending Strength | Electrode | Mpa | ≥10.5 | ≥10.0 | ≥11.0 |

Nipple | ≥16.0 | ≥16.0 | ≥18.0 | ||

Elastic Modulus | Electrode | Gpa | ≤14.0 | ≤14.0 | ≤13.0 |

Nipple | ≤18.0 | ≤18.0 | ≤17.0 | ||

Density | Electrode | g/cm3 | ≥1.65 | ≥1.64 | 1.65-1.72 |

Nipple | ≥1.72 | ≥1.70 | 1.75-1.82 | ||

Ash content | Electrode | % | ≤0.3 | ≤0.3 | ≤0.3 |

Nipple | |||||

CTE(100-600) | Electrode | 10-6/C | ≤1.5 | ≤1.5 | 1.20-1.40 |

Nipple | ≤1.4 | ≤1.4 | 1.10-1.30 | ||

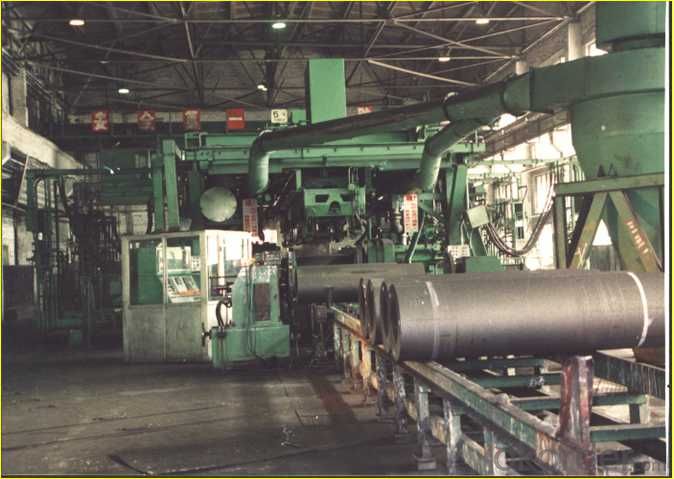

Image

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

FAQ:

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

1. Why it is essential to select electrode carefully for each particular furnace?

The primary factor is the maximum current intensity of the furnace. However, other conditions should also be considered, such as the characteristics of the furnace, type of charge, tap to tap time, oxygen blowing, mechanical requirement, furnace regulation, etc.Generally, specifications for electrodes of most grades have been standardized. Variation of physical characteristics with temperature, however, should be taken into account whenever using the electrodes.

Precautions to the use of graphite electrodes

2. Why it is essential to not to fit electrodes and nipples made by different manufacturers together?

The capacities of the furnace and the transformer determine whether the grade and diameter of the electrode are suitable to the furnace or not.

In order to prevent the electrode column from being hit by the collapsed furnace loads, large and heavy scraps should be loaded onto the bottom of the furnace. Do not put significant quantity of insulating materials such as lime and so on just under the electrode column, otherwise it would be difficult to power on the electrode column, or even break it.

electrode column may be hurt when it moves up and down if the furnace cover is out of the position.

When making a connection, lost or damaged pitch plugs must be replaced.

The reason must be found out if a gap appears between two electrodes after connection. The electrode column can only be loaded after the gap being eliminated.

The electrode column must be strictly perpendicular to the ground lever. Oblique column is not allowed during operation.

The holder must be placed between the two safety marks on the top electrode, otherwise the column may be broken.

Generally, different manufacturers may make their electrodes with different raw materials and processes, therefore the physical and chemical properties of their electrodes are usually different. Please do not fit electrodes and nipples made by different manufacturers together.

Applications

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

Electrodes in electric arc furnace and ladle refining furnace for steel making;

Electrodes in electric smelting furnace for producing industrial silicon, yellow phosphorus, corundum and so on.

- Q:The reason why graphite is used as electrode

- The graphite has good conductivity and thermal conductivityThe conductivity of graphite is one hundred times higher than that of ordinary non-metallic minerals. Heat conductivity exceeds steel, iron, lead and other metal materials. The coefficient of thermal conductivity decreases with increasing temperature, and even at extremely high temperatures, the graphite becomes hot.

- Q:The future of graphene

- Energy storage and new display areas. Graphene has excellent conductivity and transparency. As a transparent conductive electrode material, graphene has a good application in touch screen, liquid crystal display, energy storage batteries and so on. Graphene is considered to be the most potential alternative to indium tin oxide manufacturing in touch screen manufacturing, and Samsung, SONY, Hui Rui, 3M, Dongli, Toshiba and other leading enterprises have made key research and development layout in this field. Researchers at the University of Dezhou, Austen, used KOH to chemically modify graphene to form a porous structure, resulting in a storage density of ultracapacitor near the lead acid battery. Michigan Technological University scientists have developed a unique honeycomb structure of three-dimensional graphene electrode, photoelectric conversion efficiency of 7.8%, and low price, is expected to replace platinum in solar cells applications. Toshiba Co developed graphene and silver nanowires composite transparent electrode, and achieved a large area.

- Q:How about graphite electrode high-temperature oxidation resistant coating?

- Can be used, temperature characteristics of nano composite ceramic coating is more stable, and nano composite ceramic nano high temperature oxidation resistant coatings of different graphite products according to the use conditions, can the temperature of 1600 degrees, forming a dense coating on graphite coated with rust, corrosion, high temperature resistance, oxidation resistance, wear resistance and other properties.

- Q:Electrolysis of CuCl2 solutions with graphite electrodes

- CuCl2 refers to a copper chloride ionization ionization ion and chloride ion in aqueous solution, the equivalent of CuCl2 does not exist, but there are only Cu2+ and Cl-, even if there is no electricity, the ionization will happen, because this is the nature of it.

- Q:Why is graphite conductive electrode oxidized?

- Coal tar pitch is a kind of high temperature resistant graphite conductive material, which is made of coal tar pitch as binder. It is made by calcination, crushing, mixing, kneading, forming, roasting, graphitization and mechanical processing. It is called graphite electrode

- Q:Is the anode of electrolytic water suitable for ordinary titanium wires?

- The graphite is cheaper and easier to obtain, but the carbon electrodes sold in the general market are not very pure at most times. The experiment is done for a period of time, and the carbon is inexplicably broken, especially if you need to work for a long time. So, if your graphite electrode is of good quality, it's still graphite.

- Q:What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

- Q:What is the reason that the current cannot be increased when the graphite electrode is used for anode electrolysis?Add calcium chloride and sodium bicarbonate into electrolytic water

- The first answer to the equation above is quite right, or it may be that a layer of calcium carbonate is attached to the surface of the electrode, which prevents the electrode from conducting and leads to an increase in resistance

- Q:Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- In an electrolytic cell, the current from a class called graphite anode plate into the electrolyte electrolysis industry, the anode is made of plate shape, so called graphite anode plate, widely used in electroplating, wastewater treatment, industrial anti-corrosion equipment or special materials.

- Q:Do electroplating experiments, graphite as an electrode, graphite how to pre process to ensure that the coating will not fall, resulting in increased color of the solution

- Graphite as anode, generally do not need special treatment, but to choose high purity, high density, high strength (so-called "three high" graphite) graphite on the line, this graphite in brush plating operations are often used as anode material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products