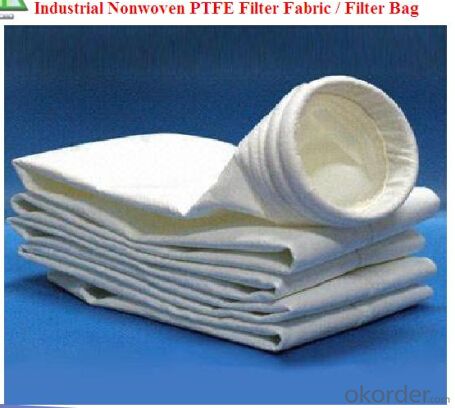

Industrial Nonwoven PTFE Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications:

The PTFE needled felt is a fiber of extremely stable chemical performance

1,Continuous operating temperatures above 250℃, the instantaneous temperature of 280 ℃.

2, Good acid & alkali resistance and oxidation resistance, non-combustible.

3, The only not aging fiber.

4, Can be used under the most adverse conditions, with extremely long service life, and usually the service life is 4 years.

specification

Description of product | TF/TF1750-W |

Fiber | 100%PTFE |

Substrates | 100%PTFE |

Square weight | 750g/m2 |

Thickness | 1.1mm |

Density | 0.68g/cm3 |

Air permeability | 90L/dm2.min |

Breaking Strength-lengthways | ≥450 N/125px |

Breaking Strength-crosswise | ≥450 N/125px |

elongation@200N/125px-lengthways | <5% |

elongation@200N/125px-crosswise | <5% |

Heat shrinkage@150degC,90min | 2% |

Bursting strength | >300 N/cm2 |

Continuous temperature | 260℃ |

Instantaneous temperature | 280℃ |

Post-processing | Heat-setting |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Packaging & Shipping

Company Information

- Q:What is the reason for the dust bag to be broken for a period of time

- This is a regular change. Bad quality is a good thing,Or it will be broken for too long.

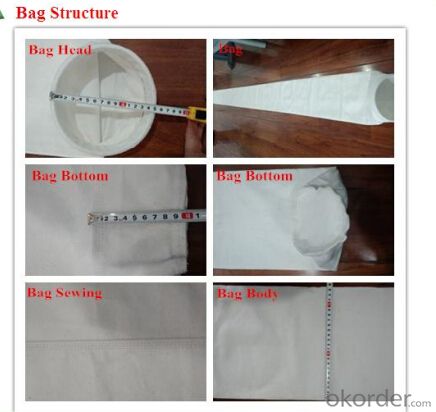

- Q:How can you not damage the filter bag when the filter bag is installed?

- The filter bag should be firmly fixed in the orifice, not too tight or too loose. When the installation is too tight, apply the rubber pile to the pocket of the filter bag and gently tap into the bag. When installation is complete, do not trample the bag. It is better to install a filter bag to install the corresponding bag.

- Q:How to buy the paint filter bag in the car painting

- Haha, it's easier for me. I want to answer the question from all the processes in the painting workshop. Pre-treatment, electrophoresis line need the following filtering material: 1, the filter bag (need) in the tub filter 2, phosphate slag filter bag/belt (need to use phosphate slag filtration system) 3, biofilm generated electrophoresis (ultra filtration membrane filtrate need) coating,... Core masterbatch 1 degreasing powder, powder formula: degreasing powder core masterbatch + base (either soda ash, sodium bicarbonate, sodium silicate) 2, alkaline water recipe: degreasing powder core super universal masterbatch + surfactant + + water + preservatives + essence 3 wire drawing powder, water-based neutral formula: super nanometer emulsifier + super oil emulsifier, wire drawing powder + water + preservatives, fragrance 4, preparation of alkaline...

- Q:Can liquid filtration bags be cleaned and reused

- Surface filter mainly adopts nylon monofilament filter bag, metal wire mesh filter bag), the surface of the filter the way for the hole interception, the interception of impurities in the filter material surface, the surface of the filter can be cleaned and secondary use. Remind: liquid filter bag this is a one-time product, under normal circumstances do not recommend repeated use, repeated use of a filter bag filter failure caused easily, at the same time also can cause cross contamination.

- Q:How to unload the washing machine's filter bag?

- Press the card in the filter bag and come down. Don't drag ah. And left and right, are there any buttons nearby

- Q:How to check the filter bag and the dust collector bag when the dust collector is installed?

- How do you do? Of filter cloth and filter bags cage with easy to check, as long as the filter bag cage on the filter bag can be, but the distance is not too big, too big can't support the role of the bag. The other skeleton should be flat on the drawing board. I don't think you carefully check the bag and drawing board hole, if the fit is not good enough, can appear leakage, bag off phenomenon, ultimately affect the efficiency of dust. Check the cloth bag to see if the cloth pocket mouth department is smooth, have not uneven phenomenon.

- Q:What do you do when the washing machine is connected to a filter bag

- Remove the filter bags, remove the wheels and use the thick wire channel

- Q:The filter bag in the washing machine is broken. How do you fix it

- In general, the filter bag of the washing machine can be removed, please read the instructions carefully, even if it is not easy to tear open come down to, as long as don't have much stuff, generally does not affect the quality of washing.

- Q:Liquid filter bags should be aware of those items when installing

- In the new filter bag, the unused filter bags must be reloaded into plastic bags to prevent dust contamination. Turn off the power supply to stop the pump and close the inlet and outlet valve (for the user who now USES the filter bag). Release the pressure, be safe, and make sure that the nozzle is heading for safety. Opening the exhaust valve slowly lowers the filter pressure (for those who now use the filter bag). Open the lid to ensure the filter pressure drops to zero and open the lid. Take out the used filter bags. (for the user who now USES a filter bag)

- Q:What is the line on the top of the filter bag?

- The plain tissue, which is difficult to clean up dust and easy to clog, is rarely used in the removal of dust

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Nonwoven PTFE Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches