Industrial Beer Brewing Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Fermenting Equipment, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: fermentation tank, KB-005

Processing Types: Alcohol

Certification: B&V; CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Image:

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

Specifications

1. interior: mirror polished, exterior: semi-luster for main body

2. material: SUS304 or 316L

3. top dish head, conical bottom

| Industrial beer brewing equipment | |

| Company introducation | We Kuangbo is a production enterprise of pharmaceutical, dairy, food and beer-making equipment, alongside biological engineering, chemical containers, and bespoke products. Our products are widely used in beer production, pharmaceuticals, beverage industries, biotechnology and other fields. |

| Usage | it is used for beer fermentation |

| Material | 1.SUS304, 316L |

| 2.jacket: dimple jacket | |

| 3.insulation layer: PU | |

| 4.as to the thickness, we can make it according to your requirement. | |

| Configuration | safty valve, CIP spraying ball and pipe at the side of the tank, outlet with valve and racking arm as your requirement, temperature gauge and sample valve |

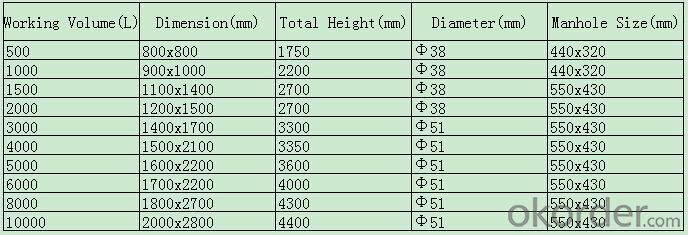

| Our advantage | 1.we can supply various kinds of volume, minimum 50L, maximun 10,000L and even larger. |

| 2.PU insulation is adopted, jacket will be dimple jacket | |

| 3.interior surface is 3Afinish and exterior is 2B finish | |

| 4.we also can equip you with a cooling system as your requirement. | |

| 5.competitive price and also higher quality tank. | |

| Minimum order | one unit |

| Payment term | T/T or L/C |

| Package | export standard package |

| Market | at home and abroad |

Technical Data:

- Q:Besides just being old, will a new gas boiler be more efficient, is it safer? What brand or how do I choose? Where should I get it? Should I hire my next door neighbor who does HVAC for a living? (I don't know if he does good work or not. Not much info on Angie's list in my area.) Could/should I install it myself? I'm not afraid - unless you say I should be. :) I have 4 programmable zones and valves. Also - should I be doing any maintenance on this boiler or a new one?

- If it is still working, I would get the gas company or contractors to give an estimate of cost and projected efficiency savings. Then decide whether to replace and then decide whether to do it yourself. Check out the needs for permits and inspections and whether you can legally do it yourself.

- Q:my landlord has left me and my 3 children with no heating or hot water for 5 wks as national grid shut my supply off coz gas leak. back boiler over 15 yr old, never been serviced. landlord says he wil allow his unreg friend to install new boiler and then get work certified by corgi reg engineer. Is this legal? am already certain it is unsafe. any answers would be very much appreciated.

- No It is illegal for anyone who is not corgi registered, to attempt installation of any gas appliance.

- Q:What is a native boiler?

- Czech engineer Muller, in the First World War, in the United Kingdom named Mark Bensheng.

- Q:Does A. Smith also produce boilers?

- Smith, of course, the production of boilers, more varieties, power from 100KW to 657KW optional, and has a small footprint, high thermal efficiency, safe and reliable, and many other advantages.

- Q:Please tell me about how boiler works in its operation, its different parts and their functions, boiler temperature and pressure, and any information you think that might help.Thank you.

- There are three basic types of boiler. 1, A simple tank made from plate steel containing a supply of water, a source of heat and distribution pipes, it is fitted with a safety valve designed to relieve excess pressure. This type is limited to pressures of less than 30 PSI. 2, A water tube type of boiler, it is more efficient than the tank type. Water is circulated through pipes that are heated by an open flame that plays over the entire length of the tubes. It also has safety valves. This type is usually used in large apartment buildings and ships. It operates at pressures of 100 PSI. 3, A fire tube boiler, this type has flame running through the pipes to boil water that is in the main body of the boiler, this is a very sturdy boiler and can produce super heated steam, it is used in ships and the pressure is 100 PSI.

- Q:How to improve efficiency of Boiler?

- Improving the efficiency of boiler is becoming a wide spread concern. I hope by 'boiler efficiency', you mean 'Thermal Efficiency' i.e. fuel-to-steam efficiency. In order to IMPROVE the efficiency, first evaluate the existing efficiency of the boiler and then take steps to improve its efficiency. The following are the key factors that play a vital role in the evaluatio of effficiency calculations: 1. flue gas temperature 2. fuel specification 3. excess air 4. ambient air temp 5. radiation and convection losses Some simple industrial measures (among many many others) to improve boiler efficiency are as under: 1.minimize excess air levels 2.use feed water economizers for waste heat recovery. 3. proper timing of blowdowns 4. installation of boiler blowdown heat recovery. 5.minimize stack losses 6. treat feed water to avoid build up of scales and piting of heating surface 7. install condensate recovery system to pre-heat feed water There are many other options available to improve the efficiency of a boiler. In the end, I would just like to emphasize that Monitoring is the most important aspect of the task. Schedule a periodic monitoring plan to evaluate the efficiency

- Q:I have a boiler that heats my house. It is approximately 10-15 years old. When the guy who sold me the house gave me a walk around to explain a few things he remarked that the boiler pressure was higher than he'd seen before. (the pressure was between 15-20).I was looking at it today and it was at 25, and I had the heat turned down to 60 degrees F, so it wasn't working too hard.It has an automatic water filling function, so that when the water gets too low it fills back up. (the water line is in the middle of where it is supposed to be.I've routinely, once every 2 weeks, drained some of the dirty water from the boiler to prevent build up.Is the pressure build up normal?Is there maintenance that I should have been doing for the past couple years.Any advice would be greatly appreciated.ThanksMark

- The pressure reading is too high. Check the pressuretrol (cut-out ) setting .It should be low. Nearly all residential steam systems should heat on ounces not pounds. Take apart the coiled pipe ( PIG TAIL ) that the control mounts onto and make sure it's not clogged with scale. Make sure that the gauge shows zero on a cold boiler, because the gauge could be faulty. I don't mean to be long winded but it could mean it's time to service (replace ) the vents on the radiators if it's a 1 pipe system (1pipe going to radiator ), or the steam traps on the rads if it's 2 pipe.

- Q:I have the timer set to come on 3 times a day. Is the gas supposed to come on in between these times? (I dont wanna make the house explode!) I have never seen a boiler before I came to England. Help?

- Hi. A boiler is filled with water, and fire, fueled by gas or oil or sometimes other combustibles heat the water and turn it to steam. The steam travels thought the pipes of the house to floor heaters or old radiators. These heat up and warm the room. The stream cools down and returns to a water and flows back to the boiler to be heated again to steam next time the house needs it. It is very hard to blow a boiler because it is a closed system. I mean that unless you have a really big dump of a house, the water cannot escape the pipes or the boiler, and it will not really evaporate into the air enough in a year to do damage. For me, in the summer I drain all the water oUT of my boiler and refill it with clean water to keep rust from building up in the system. b ut I suggest that the Gas Company will help you to get on a maintenance schedule and they will come out and do this for you So the only way to blow a boiler is to run out of water!

- Q:what is the difference between ASME S stamp and BS 12952?

- Offhand, probably one's American and one's British. BS is usually British Standard

- Q:So I had the heating on this morning and all of a sudden I hear a pop noise and my boiler started making this hissing sound. Sounds like someone has turned a tap on full. So I switched it off and the noise just continued. I can also hear the sound in the radiators as well. Council won't come and fix it till Monday afternoon. I'm just wondering what could be the reason for the noise? It's had me worried/irritated all day. I live in a flat so turning off the water etc not an option.

- Presuming this is a hot water boiler: The boiler pressure relief valve is popping off. Pressure has reached the point where the valve opens automatically to protect the boiler from damage do to excess pressure. It is often an indication of a problem with some other boiler component. It should be addressed soon by the landlord, as the popoff is kind of the last like of defense and could result in an expensive repair. When the valve releases, it emits hot water and steam, so stay clear of the boiler. Leave this to the landlord and the professionals he/she hires.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Beer Brewing Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches