Industrial Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications:

Compositions | polyester fiber | |

Weight (g/ m2) | 500 | |

Thickness (mm) | 1.8 | |

Air permeability (L/m2/s) | 150-300 | |

Tensile strength | 1200 | 1250 |

1300 | 1350 | |

Tensile Elongation(%) | <20< span=""> | <30< span=""> |

<45< span=""> | <30< span=""> | |

Broken strength | 2.40 | |

Continuous working temperature(°C/°F) | 140/284 | |

Short time Working temperature(°C/°F) | 160/320 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | good | |

Finishing treatment | Singeing, calendaring, plain, Heat Set | |

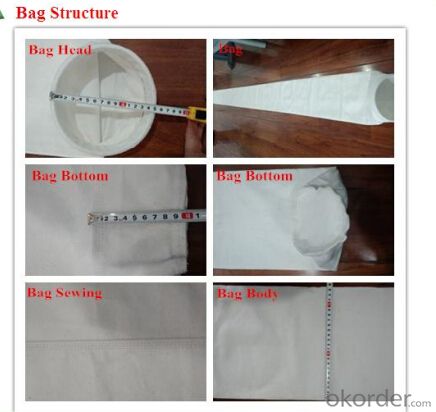

Top load/ entry(walk-in plenum) | Snap Band | |

Bottom load/ entry(common in bin vents) | Disk With Wear Strip | |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Antistatic Constructions

electrical conductive

Optimum discharge of electrostatic charges, therefore suitable for potentially explosive areas, as well as for electrostatic, strongly chargeable/charged dusts.

permanent electrical conductive in accordance with DIN 54 345 part 1 by adding stainless steel fibres into the fibre mass in accordance with DIN 54 345 part 1 or

alternative in support of scrim in accordance with DIN 54 345 part 1 and part 5

Packaging & Shipping

Company Information

- Q:Why is the filter bag material PE a polyester, not a polyethylene

- PE (Polyethylene) : Polyethylene, is the most simple structure of high polymer organic compounds, in today's world the most PE Polyethylene widely used polymer materials, composed of ethylene polymerization.

- Q:How is the filter material processed by the filter bag?

- First, the cloth will be made of polyester staple fabric that will be woven into the fabric of the fabric, which will form a short line covering the pores of the fabric. Compared with the average machine, the dust layer is more easily formed after the nap, and the dust rate is higher (99.5%).

- Q:How to buy the paint filter bag in the car painting

- Haha, it's easier for me. I want to answer the question from all the processes in the painting workshop. Pre-treatment, electrophoresis line need the following filtering material: 1, the filter bag (need) in the tub filter 2, phosphate slag filter bag/belt (need to use phosphate slag filtration system) 3, biofilm generated electrophoresis (ultra filtration membrane filtrate need) coating,... Core masterbatch 1 degreasing powder, powder formula: degreasing powder core masterbatch + base (either soda ash, sodium bicarbonate, sodium silicate) 2, alkaline water recipe: degreasing powder core super universal masterbatch + surfactant + + water + preservatives + essence 3 wire drawing powder, water-based neutral formula: super nanometer emulsifier + super oil emulsifier, wire drawing powder + water + preservatives, fragrance 4, preparation of alkaline...

- Q:What are the characteristics of a liquid filter bag?

- , good heat resistance, can be used under 280 ℃ for a long time Dust is easy to peel off The dimension stability is good, the fiberglass itself does not contract at the standard temperature

- Q:What kind of bag is used in the food industry

- Liquid filtering in the food industry is usually filtered through a nylon filter bag. The filtration of juice, drink and milk usually USES a single-layer filter bag of PP or PE, which can be used to filter the site and is relatively economical. Higher filtering requires absolute precision and 99.9% of special high-end filter bags depending on the situation.

- Q:How does the filter bag work?

- Mechanical vibration wave sootblower is often used in small single cartridge filter, it is the use of filter plate produced by the eccentric gear on shaking power to clear the ash, this action need downtime after operation.

- Q:Problem with the washing machine filter bag

- You can see, if you wash the clothes, pulsator every time turn, your filter bag whether there will be a lot of water came out of it, even the filter bag holder? If so, your filter bag must be working. If the filter is not reflected when the wheel is rotating, it is not the channel that is blocked by your filter. There's a problem with the blade under your wheel. Because the fiber filter bag impurity is to rely on the blade under the pulsator the dirty water out of the dolly tub contains fiber impurities into the filter bag out, the waterway that through the filter bag, the fiber impurity on the filter bag, and the water will flow back to dolly tub. So if the blade breaks, it won't be able to catch the water. Of course, water and fiber impurities don't go into the filter bag

- Q:Who has used a liquid filter bag? What is its feature?

- The filtration efficiency is high, can reach more than 99.5% Expanding filter cloth (bag), improving filter wind speed and filtration efficiency, reducing the volume of dust removal equipment

- Q:How about all the filters in the washing machine

- Either use a silk sock instead of using it, or buy a new one after the sale.

- Q:Liquid filter bags should be aware of those items when installing

- In the new filter bag, the unused filter bags must be reloaded into plastic bags to prevent dust contamination. Turn off the power supply to stop the pump and close the inlet and outlet valve (for the user who now USES the filter bag). Release the pressure, be safe, and make sure that the nozzle is heading for safety. Opening the exhaust valve slowly lowers the filter pressure (for those who now use the filter bag). Open the lid to ensure the filter pressure drops to zero and open the lid. Take out the used filter bags. (for the user who now USES a filter bag)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords