Industrial 0.2 0.3mm 3003 3004 3105 Cold Rolling Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

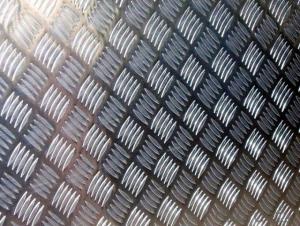

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q:Do aluminum cans melt in typical campfires? I know the melting point is about 660 Celsius but do campfires get that high? I thought it would just be that the can becomes disfigured and collapses due to the heat, not due to it melting. Even if it did melt in the fire how would you find the remains? The can in a liquid form would certainly not be confined to one part of the fire and therefore wouldn't solidify in a small pool to see if it had melted or not. Any ideas?

- Aluminium is very easily oxidized (in its solid form, a thin layer of very though aluminium oxide protects the metal). Put it in a fire, and that oxide will be removed, and 100% of the metal will oxidize, leaving nothing but aluminium oxide white powder behind.

- Q:What are the environmental benefits of using aluminum sheets?

- There are several environmental benefits associated with using aluminum sheets. Firstly, aluminum is a highly recyclable material, meaning that it can be recycled repeatedly without losing its quality or properties. This reduces the need for mining and extraction of new aluminum ore, which can contribute to deforestation, habitat destruction, and water and air pollution. Recycling aluminum sheets also requires significantly less energy compared to producing new ones, resulting in reduced greenhouse gas emissions and a smaller carbon footprint. Additionally, aluminum sheets are lightweight, which makes them a more sustainable alternative to other materials such as steel or plastic. The use of aluminum sheets in various industries, such as automotive and aerospace, can help reduce the overall weight of vehicles and aircraft, leading to improved fuel efficiency and lower emissions. This is particularly important in the context of climate change and the need to reduce our dependence on fossil fuels. Furthermore, aluminum is corrosion-resistant, durable, and long-lasting, making it a sustainable choice for various applications. Its durability reduces the need for frequent replacements, thereby reducing waste generation. Moreover, aluminum sheets can be used in construction to improve insulation, leading to energy savings and reduced greenhouse gas emissions. Lastly, aluminum is non-toxic and does not release harmful pollutants during its production or use. This makes it a safe material choice for various applications, including food packaging and medical equipment. In summary, the environmental benefits of using aluminum sheets include its recyclability, lightweight nature, energy efficiency, durability, and non-toxicity. By choosing aluminum sheets over other materials, we can contribute to reducing resource extraction, energy consumption, greenhouse gas emissions, and waste generation, while promoting a more sustainable and environmentally friendly future.

- Q:Where is the difference between the 5052 aluminum plate and the 1060 Aluminum plate?

- Ingredients:5052 alloy aluminum (aluminum magnesium alloy, aluminum content of about 95%, magnesium content of about 4%, as well as some other trace metal elements)1060 is pure aluminum (aluminum containing 99.6%, margin for other metal elements)Physical property:Similarly, the two kinds of aluminum, 5052 to 1060 higher in hardness, elongation, tensile strength and so on are not the same. What are the specific states (H14, H32, H24, O, etc.)?Prices are usually 5052 above 1060. How much specific higher, according to different manufacturers and production processes vary.

- Q:1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- Al is not reactive because it is so reactive - it gets coated with oxide immediately on exposure, the oxide layer is strong and quite inert except to strong acids.

- Q:A sample of aluminum and a sample of steel have superficially identical microstructures. Which would you expect to be stronger, and why?

- as far as i know we have an alloy named dur alumin cosists of Al, alloying element especially Mg it is as strong as steel .

- Q:What is the lifespan of aluminum sheets?

- The lifespan of aluminum sheets can vary depending on various factors such as their usage, environment, and maintenance. However, when properly cared for, aluminum sheets can last for decades or even a lifetime due to their inherent resistance to corrosion and durability.

- Q:Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is a widely used material in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and formability. It offers durability and structural integrity while keeping the weight of the aircraft relatively low. Aluminum sheets are commonly used for constructing aircraft panels, providing a reliable and efficient solution for aerospace applications.

- Q:Can aluminum sheets be laser cut?

- Indeed, it is possible to laser cut aluminum sheets. Laser cutting is widely favored for its remarkable accuracy and efficiency when it comes to cutting aluminum sheets. This cutting technique entails employing a high-powered laser to either melt or vaporize the material, resulting in a precise and neat cut. Due to its high reflectivity, aluminum necessitates a laser with greater power to effectively penetrate through it. Nevertheless, once the appropriate laser parameters are established, laser cutting machines can easily and precisely cut aluminum sheets. This method finds extensive application in industries such as automotive, aerospace, and manufacturing, where aluminum sheets are utilized for various purposes.

- Q:What is the typical weldability of aluminum sheets?

- Aluminum sheets have good weldability due to their high thermal conductivity and low melting point.

- Q:Can aluminum sheets be used for electrical applications?

- Yes, aluminum sheets can be used for electrical applications. Aluminum is a highly conductive material, with nearly 60% of the electrical conductivity of copper. This makes it suitable for various electrical applications such as wiring, bus bars, transformers, and electrical panels. Aluminum sheets are commonly used in the construction of electrical enclosures and housings due to their lightweight and corrosion-resistant properties. Additionally, aluminum is cost-effective compared to other metals like copper, making it a popular choice in many electrical applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial 0.2 0.3mm 3003 3004 3105 Cold Rolling Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords