Induction Forging Furnace (ORD-15KW-300KW)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

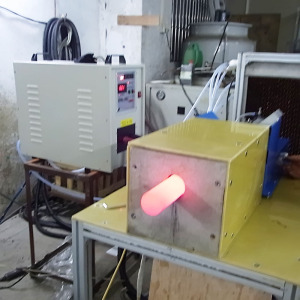

MF Forging Furnace:

Advantage:

1 More than ten years experience, stable and goods performance

2 CE certificated

3 Copperated with ZHOUDAFU, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

4 Suitable for different bars to forging

5 Two transformer ratios, can match better different length induction coil

6 The Frequency can reach to 1kHz

1 Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2 100% Duty cycle, continuous working is allowed at maximum power output.

3Display of heating power and heating current and oscillating frequency;

4 Simple to install, Installation can be done by unprofessional person very easily;

5 Light weight

6 Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

Advantage:

1 More than ten years experience, stable and goods performance

2 CE certificated

3 Copperated with ZHOUDAFU, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

4 Suitable for different bars to forging

5 Two transformer ratios, can match better different length induction coil

6 The Frequency can reach to 1kHz

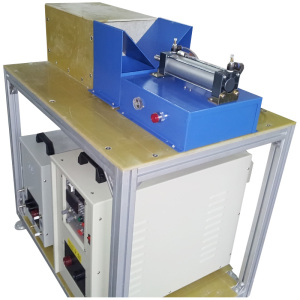

7 Automatic feeding system, save workers, improve efficiency

1 Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2 100% Duty cycle, continuous working is allowed at maximum power output.

3Display of heating power and heating current and oscillating frequency;

4 Simple to install, Installation can be done by unprofessional person very easily;

5 Light weight

6 Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

- Q:What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

- Q:Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q:Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- Heat treatment furnace is mainly for the mechanical processing and casting industry workpiece annealing, quenching, carburizing, quenching and tempering, heat treatment equipment.

- Q:What are the advantages of a vacuum furnace?

- Energy consumption is lower than salt bath furnace. Modern advanced vacuum industrial furnace heating chamber is made of high quality heat insulation material and wall, which can concentrate electric heating energy into heating chamber with remarkable energy saving effect.

- Q:How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

- Q:Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q:Brief introduction to repair of industrial furnace

- Although the number of industrial furnaces in general machinery plants is not large, the number of large repairs per year accounts for 16%-20% of the total number of repairs for all equipment, and the large repair costs account for about 18%-25% of the total repair cost of all equipment.

- Q:Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q:What is industrial furnace masonry?

- Before masonry construction, the pre process and parts that may affect the quality of masonry work shall be re tested,masonry construction shall be carried out according to the datum central line and the datum elevation.

- Q:How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Induction Forging Furnace (ORD-15KW-300KW)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products