Iinjection Molding Machine LOG-210A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG210-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 347-520 g

Clamping Force: 2100 kn

Opening Stroke: 480mm

Power(W): 18.5 KW

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Screw Diameter: 45-50-55 mm

Injection pressure: 145-217 mpa

Function: Plastic Injection Molding Machinery

Space between Tie Bar: 510*510mm

Material: Stainless Steel

Product Type: PP PE PVC ABS

Warranty: One Year

Packaging & Delivery

| Packaging Details: | Packaging Details: 20 GPcabinet Delivery Detail: In one week after get payment |

|---|

| Description | Unit | LOG-210A8 | ||

| international recognized models | 830/210 | |||

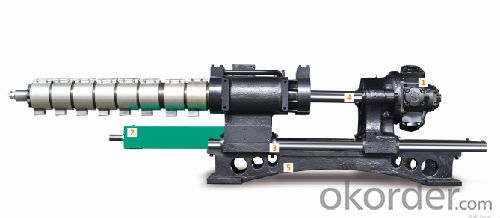

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 381 | 470 | 569 |

| Shot volume | g | 347 | 429 | 520 |

| Oz | 12.1 | 15 | 18.1 | |

| Screw diameter | mm | 445 | 50 | 55 |

| Injection diameter | mpa | 217 | 176 | 145 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| Scerw steoke | mm | 240 | ||

| Screw rotate speed | r/min | 0-200 | ||

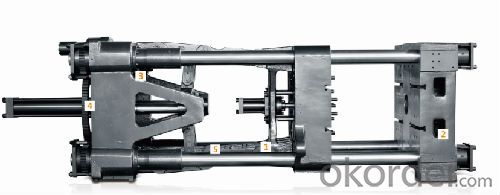

| CLAMPING UNIT | ||||

| Clamping force | kN | 2100 | ||

| Opening stroke | mm | 480 | ||

| Platen size | mm*mm | 745*745 | ||

| Space between tie bars | mm*mm | 510*510 | ||

| Maldthickness | mm | 200-550 | ||

| Platen Mix stroke | mm | 1030 | ||

| Ejection stroke | mm | 150 | ||

| Ejcetion force | kN | 67 | ||

| Power/Elcetric Heating | ||||

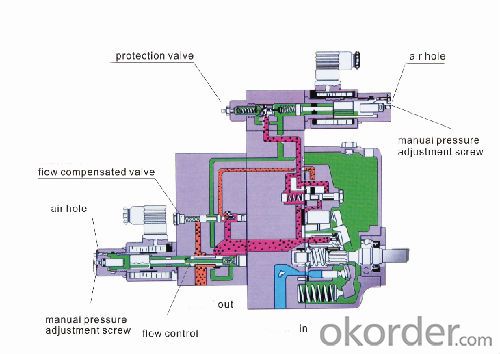

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7 | ||

| Heating power | kw | 13.1 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 4.5 | ||

| Tank volume | L | 310 | ||

| Machine dimesions | m*m*m | 5.4*1.32*2.1 | ||

| Weight of machine | kg | 6800 | ||

- Q:Relative to the size of the installation mold, it can also be said to be the internal column or guide column of the injection molding machine. How can this part be translated in English?

- Tie Bars--- pull rod (Ge Linzhu)Clearamce Between Tie Bars is the column spacing is between the Green column, you said the distance, Green column spacing also restricted the installation of the width of the mold, the mold width must be less than the Green column spacing can be put under the lock on shot out!

- Q:We are going to an injection molding machine factory at once. I don't know yet which is what I learn, NC, please master, and hope to be able to put the knowledge about injection molding machine told me, I appreciate the injection molding machine is that NC programming ah | please master, thank you

- The injection molding machine is not the NC plastic raw material is heated to a certain temperature and then injected into a mold for molding machine and injection molding machine as you learn, programs are specified, the factory will die mode system set! Not often programmed! (procedure: locking - injection - sol - cooling - mold - Loosening the top has been circulating) of some function of injection molding machine is not the same, is only the function of a computer system (just not the same, is equivalent to XP and W7) injection molding machine can be divided into 4 systems: the locking system, injection system, hydraulic system, electric control system, you said is programming control system!I can't think of that much, just tell you, you've got it, you don't understand, you can communicate!

- Q:when the material stored, the screw has been in situ, and will not go back to the set stop position. What shall I do?

- When the material storage, you look at the nozzle has no material, if there is no transfer under the pressure, if you look at the material hopper have feed tube material, if there are very thick material in the hopper below the card down to the tube without glue, will have to screw in the back. Not always

- Q:What is the fluctuation of the screw speed of injection molding machine?

- Screw speed fluctuation of injection molding machineFor isothermal Newton fluid, the volumetric flow rate (Q) of the extruder is proportional to the isothermal Newton flow, and the extrusion flow rate is proportional to the screw speed. This relationship has important guiding significance for production practice. It shows that the output of extruder can be greatly improved by increasing the rotational speed. The history of the development of single screw extrusion machine also increases the speed of ladle is one important way to improve the production capacity of a single machine and the actual extrusion process flow rate and screw speed q is not completely linear, this is mainly because we are in these formulas of the melt viscosity, outlet pressure, melt rheological properties were simplified processing.

- Q:How does the injection machine prevent the product from sputtering to the machine? As for the question, how can I solve it perfectly?

- It's time to slow down. Is it a launch rocket? It's too vigorous. Not really. Just use a cardboard file

- Q:How to debug the injection molding machine? solve

- You ask too many questions, and debugging involves so many things. If you mean that a process problem is not clear, or you can do other debugging on the injection machine, you can write it out. Plastic injection is not difficult. As long as you are willing to learn, you will not succeed if you depend on it

- Q:What plastic injection machines and materials are needed for making plastic waste shovels?

- Should use horizontal injection molding machineThere are several kinds. Pc.pom.pp.pa66+30%, see how you choose it.

- Q:What are the injection molding machine brands in China?

- Factors affecting user purchasesIndustry trends in the purchase of injection molding machines by users5, the survey of purchasing plan shows that 51% of users have purchasing plan. Among them, foreign-funded enterprises accounted for 40%, private enterprises accounted for 30%, joint-stock enterprises more than 20%, while state-owned enterprises less than 10%. Most of these users of the purchase plan belong to the automotive industry, followed by the packaging and electronic communications equipment industry.6, when asked whether the user will buy again in the use of brand, 36% of users are positive, 14% of users clearly will not, 50% of users expressed uncertainty.That is, the number of respondents surveyed and many factors such as uneven distribution of trade restrictions, although the investigation has a certain objectivity, but can not fully reflect the real situation of the market, only for your reference.

- Q:How will the screw speed of injection molding machine be adjusted slowly?

- In the screw speed adjustment, from the lower speed start, gradually commissioning to higher speed, and then determine the screw speed.The working speed of the screw of the injection machine is unstable and is affected by the following factors:1, drive V belt wear seriously, slipping when working.2, V belt drive belt wheel center distance is too small, so that belt drive can not and belt pulley trapezoidal slope correct friction drive work.3. The temperature of the heating material in the barrel is low, and the material is not uniform, which leads to the screw rotation of the injection machine, the increase of the working load torque, and the instability of the screw speed of the injection molding machine.4, injection molding machine screw thrust bearing damage, etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Iinjection Molding Machine LOG-210A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords