IF 5-60t MF Induction Furnace

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | normal export package |

| Delivery Detail: | 3-6 months |

Specifications

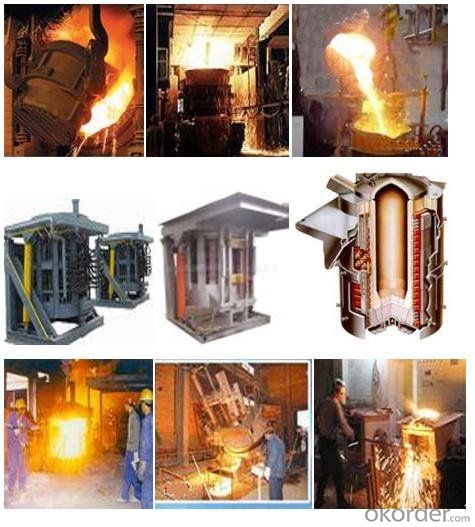

1.casting,melting

2.medium frequency melting furnace

3.steel shell mf furnace

4.energy saveing mf furnace

5.keep temperature

5-60t Medium Frequency Induction Furnace MF Induction Furnace

1. casting, melting metals mf furnace

2. keep temperature mf furnace

3. steel shell mf furnace

4. energy saving mf furnace

5. AC power: work, medium, high frequncy mf furnace

6. melting many metals

Character

1. Induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. It is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting.

2. Induction furnace capacities range from less than one kilogram to one hundred tonnes capacity and are used to melt iron and steel, copper, aluminium and precious metals. Since no arc or combustion is used, the temperature of the material is no higher than required to melt it; this can prevent loss of valuable alloying elements.

3. Operating frequencies range from utility frequency (50 or 60 Hz) to 10000 kHz or higher, usually depending on the material being melted, the capacity (volume) of the furnace and the melting speed required. Generally, the smaller the volume of the melts, the higher the frequency of the furnace used; this is due to the skin depth which is a measure of the distance an alternating current can penetrate beneath the surface of a conductor. For the same conductivity, the higher frequencies have a shallow skin depth - that is less penetration into the melt. Lower frequencies can generate stirring or turbulence in the metal.

4. A preheated, 1-tonne furnace melting iron can melt cold charge to tapping readiness within an hour. Power supplies range from 10 kW to 15 MW, with melt sizes of 20 kg to 30 tonne of metal respectively.

5. An operating induction furnace usually emits a hum or whine (due to magnetostriction), the pitch of which can be used by operators to identify whether the furnace is operating correctly or at what power level.

Specification

| Furnace Model | Rated Capacity (T) | Max Capacity (T) | Rated Power (KW) | Rated Frequency (KHZ) | Voltage (V) | Output Voltage (V) | Oven Voltage (V) | Pulses | Melting Rate (T/H) | Melting Time (Min/Furnace) | Energy Consumption (KWH) | Transformer Capacity (KVA) | Water Cooling (T/H) |

| GW-10-6000/0.5 | 10 | 11 | 6000 | 0.5 | 1000 | 1650 | 3400 | 12 | 9 | 75 | 500 | 6300 | 80 |

| GW-12-7500/0.25 | 12 | 13 | 7500 | 0.25 | 1000 | 1650 | 3400 | 12 | 10 | 75 | 500 | 8000 | 100 |

| GW-15-9000/0.25 | 15 | 16 | 9000 | 0.25 | 1000 | 1650 | 3400 | 12 | 13 | 75 | 480 | 9000 | 130 |

| GW-20-12000/0.25 | 20 | 22 | 12000 | 0.25 | 1000 | 1650 | 3400 | 24 | 15 | 80 | 460 | 12000 | 180 |

| GW-25-15000/0.25 | 25 | 27 | 15000 | 0.25 | 1000 | 1650 | 3400 | 24 | 18 | 90 | 450 | 15000 | 220 |

| GW-30-18000/0.15 | 30 | 32 | 18000 | 0.15 | 1000 | 1650 | 3400 | 24 | 20 | 100 | 450 | 18000 | 280 |

| GW-40-25000/0.15 | 40 | 43 | 25000 | 0.15 | 1000 | 1650 | 3400 | 48 | 25 | 100 | 440 | 20000 | 380 |

| GW-50-30000/0.15 | 50 | 53 | 30000 | 0.15 | 1000 | 1650 | 3400 | 48 | 30 | 100 | 430 | 22000 | 480 |

- Q:What's the role of anchor bricks in industrial furnaces?

- These layers need to be joined and anchored. Anchor brick is this role. The heat insulation layer at the horizontal section of the flue is mostly a narrow cavity.

- Q:What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

- Q:Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q:What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q:Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- Heat treatment furnace is mainly for the mechanical processing and casting industry workpiece annealing, quenching, carburizing, quenching and tempering, heat treatment equipment.

- Q:How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q:What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q:What is industrial furnace masonry?

- Pre construction and recording shall be carried out on complex and important parts of industrial furnaces,masonry of all kinds of masonry shall be made with staggered joint masonry.

- Q:How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q:What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

IF 5-60t MF Induction Furnace

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products