ID 15 Tower Scaffolding System with Hot Dip Galvanizing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

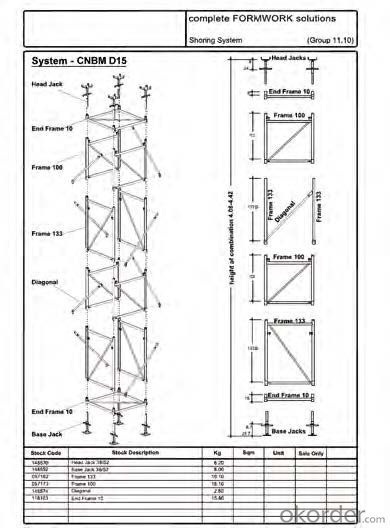

1.Structure of ID 15 Scaffolding Description:

ID15 Scaffolding system is consists of base head,frame 133,frame 100,end frame,diagonal),can be tower,widely used in bridge project.

2.ID 15 Scaffolding advantages:

ID 15 Scaffolding adapts flexible to any wall geometry

Fast due to pre-assembled panels with built-in plywood

Economical due to longer service life and fewer parts

Hire option given in selected regions

Hot selling ID 15 Scaffolding with low price

3.ID 15 Scaffolding Products pictures:

4.ID 15 Scaffolding Specification:

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

1)How many Scaffolding your company have?

Here comes our 5 types of Scaffolding systems:

- Cup lock Scaffolding(C-Lock Scaffolding)

- Ring lock Scaffolding

-Kwistage Scaffolding

-H-frame Scaffolding

-ID15 Scaffolding Tower, this type Scaffolding is the most widely used in construction, such like bridge.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q:Can you identify Scaffold Grade Aluminum tubing by looking at it.?

- The grade or type of Aluminum Alloy materials can not be identified visually because they are almost all the same in appearance. Normally these materials are marked with there Alloy number or designation like, 6061- T6, at certain intervals so that users can distinguish them.

- Q:I got an industrial/scaffold piercing a few months ago and currently have captive bead rings in (The piercer put those in after he pierced it). The piercings are now healed enough for me to change the piercing, and I found an industrial bar on ebay which I'd really like to order. Only problem is, it has two choices on the gauge thickness and length, and I don't know which mine is.The gauge sizes available are 1.2mm (16g) or 1.6mm (14g) , and the length options are 32mm, 35mm, 38mm.Does anyone know which would be the best to get? Thanks.

- Please ignore the the bigger the better idea. A longer bar can be as bad in an industrial piercing as a shorter bar can be. It really depends on what size you were pierced with...16g o 14g. Industrial piercings are typically done at 14g, 16g would be too small. The length depends on your anatomy...you really should go to a professional piercer to get the bar put in since your piercings aren't completely healed. That way everything can be 100% sterile and they will be able to fit the proper length of jewelry into your ear.

- Q:Scaffold removal should comply with those requirements......

- Demolition safety requirementsThe removal order should be 1 layers from the top down, at the same time no homework.2 remove the frame rods and connectors, springboard and other materials, should be used in rolling, prohibited throw down. The foot lever and remove the plate have been demolished, should be disposable.3 all the pieces of the wall should be removed from the scaffold layer by layer, it is strictly forbidden to take the whole or a few layers of the demolition of the wall and then dismantle the scaffolding; the demolition of the height difference should not be greater than two steps, such as the height difference is greater than the two step should be added to strengthen the wall.4 when the scaffolding removed to the lower part of the last long steel pipe height, according to the needs of the site in the appropriate position to take temporary support reinforcement, after the demolition of the wall.

- Q:What are the full house scaffolding specification

- 5 "technical code for safety of steel tubular scaffold for building construction" (JGJ128-2000)6 "construction formwork safety technical specifications" (JGJ162-2008)

- Q:New features of quick dismantling scaffolding?

- Preservative treatment: Advanced electrophoresis paint treatment, both inside and outside the paintCorrosion effect is longer than the traditional painting and painting steel tube life of 5-8 years

- Q:A 520 kg box sits 1.4 m from the left end. What is the tension in the right hand side wire? (g = 9.8 m/s2) ____________ Newtons

- Because the scaffold is not moving, we can assume that the net Torque acting on the scaffold equals zero. Net Torque = 0 torque = Force x distance (d) Use the left end of the scaffold as the center point. This will eliminate the Torque caused by the left wire (d = 0, so torque = 0) There are now three forces creating torque on the scaffold. There is the weight (m x g) of the scaffold, at 3.5m from the left end. m1 x g x 3.5m There is the weight of the crate, located 1.4m from the left end: m2 x g x 1.4m These two torques are countered by the torque caused by the Tension (T) of the right wire, located 7m from the left side. T x 7m The sum of these torques is zero. (T x 7m) - (m1 x g x 3.5m) - (m2 x g x 1.4m) = zero solve for T T = ((m1 x g x 3.5m) + (m2 x g x 1.4m)) / 7m T = ((115kg x 9.8m/s^2 x 3.5m) + (520kg x 9.8m/s^2 x 1.4m)) = 1.58 x 10^3 N Hope this helps.

- Q:Erection of scaffolding accessories

- Erection of scaffolding accessories:Door frame should be installed from one end to the other end of the extension, and layer by layer to change the direction of the set, not the opposite. After the completion of one step, should check and adjust its level and verticality. Scaffolding should be built around the building, continuous, synchronous erection elevation, in the form of a closed structure around the building; if not closed, the scaffold should be added at both ends of the wall.

- Q:Construction, outdoor double scaffolding a square meter how many meters of steel pipe and how much?

- Steel pipes need to be equipped with 210-220 fasteners, 90% of the cross fastener

- Q:When putting up old scaffolding, a mistake was made and it had to come down.Long story short, the connectors between the vertical and horizontal poles (which were hammered in) are stuck.Any ideas for getting them out?Thanks.

- WD 40, angle grind off what you can.

- Q:If I know the length , width and height of the area for the scaffold, how do I calculate the tonnage?

- tonnage is related to the volume of a certain material to be used in a certain project... so as to volume, tonnage is just the volume of the material to be used, given the specifiations in this case, scaffolds. consult your design and count the distribution of the scaffolds to be used.. average ratio of scaffolding tonnage is a ton per 10 square meter... also depends on the quantity of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ID 15 Tower Scaffolding System with Hot Dip Galvanizing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords