I Beam Steel YBT24 for Mining Applications with Large Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of I Beam Steel YBT24 for Mining Applications with Large Sizes Description:

I beam steel YBT24 for mining applications with large sizes is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". I beam steel YBT24 for mining applications with large sizes is usually made of structural steel and is used in construction and civil engineering. The I beam steel YBT24 for mining applications with large sizes resists shear forces, while the flanges resist most of the bending moment experienced by the beam. I beam steel YBT24 for mining applications with large sizes theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of I Beam Steel YBT24 for Mining Applications with Large Sizes:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

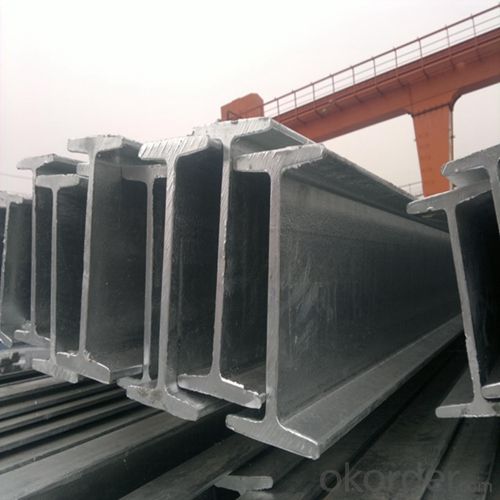

3. I Beam Steel YBT24 for Mining Applications with Large Sizes Images:

4. I Beam Steel YBT24 for Mining Applications with Large Sizes Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:Can steel I-beams be used for curtain walls?

- Curtain walls cannot be constructed using steel I-beams. Typically, aluminum or glass is used to construct curtain walls, as they must be both lightweight and transparent. Steel I-beams, on the other hand, are heavy and do not possess the necessary properties to support the weight of glass panels while maintaining structural integrity. Moreover, steel I-beams fail to provide the desired aesthetic appeal and design flexibility essential for curtain walls.

- Q:Relationship between H steel and I-beam, C section steel and channel steel

- The classification of C type steel is numerous, including: galvanized, hot galvanized cable tray, glass curtain wall, ranging in shape, edge line, car profile. Channel steel can be divided into light channel steel, ordinary channel steel, hot rolled channel steel, cold bend equilateral / unequal channel steel, cold bend inner / outer side channel steel channel.

- Q:How are steel I-beams manufactured?

- Hot rolling is the method used to manufacture Steel I-beams. The process begins by heating a large rectangular billet of steel until it becomes malleable and can be shaped into the desired I-beam profile. Subsequently, the billet is passed through a series of rolling mills that progressively shape it into the final I-beam shape. To initiate the hot rolling process, the billet is heated in a furnace to a specific temperature, typically around 1200 to 1300 degrees Celsius. This elevated temperature increases the steel's ductility and makes it easier to form. Once the desired temperature is reached, the billet is fed into the first rolling mill. The rolling mill comprises a set of rollers that gradually transform the heated billet into the I-beam profile. By applying pressure to the steel, the rollers elongate it and give it the desired shape. As the billet passes through each set of rollers, it becomes progressively thinner and longer, and the top and bottom flanges of the I-beam start to take form. After the initial rolling mill, the partially formed I-beam undergoes further shaping in subsequent rolling mills. These mills continue to apply pressure and refine the shape of the I-beam until it reaches its final dimensions. The final step in the hot rolling process involves cooling the newly formed I-beam to room temperature, which can be achieved through air cooling or water quenching. Once the I-beams have been cooled, they are cut to the desired length and undergo any necessary additional processing, such as surface treatments or galvanization. At this point, they are ready for use in various construction projects, where their strength and structural integrity make them an ideal choice for supporting heavy loads and spanning long distances.

- Q:How do you calculate the maximum bending moment for a steel I-beam?

- The maximum bending moment for a steel I-beam can be calculated using the formula M = (W * L^2) / 8, where M is the maximum bending moment, W is the total applied load, and L is the span length of the beam.

- Q:How do steel I-beams perform in terms of snow load resistance?

- Steel I-beams are widely recognized for their exceptional snow load resistance. The structural design of steel I-beams allows them to effectively distribute the weight of snow loads, ensuring optimal support and stability. The shape of the I-beam, with its wide flanges and narrow web, grants it superior strength-to-weight ratio, making it highly efficient in handling heavy loads. Additionally, steel is a strong and durable material that can withstand the pressure and weight of accumulated snow without significant deformation or failure. This makes steel I-beams a reliable choice for structures located in regions with heavy snowfall, as they can effectively bear the weight and maintain structural integrity, ensuring the safety and stability of the building.

- Q:How do steel I-beams contribute to the overall sustainability of a building?

- Steel I-beams contribute to the overall sustainability of a building by providing structural stability, durability, and recyclability. Their high strength-to-weight ratio allows for efficient use of materials, reducing the amount of steel required and minimizing the environmental impact of extraction and transportation. Moreover, steel is a highly durable material that can withstand extreme weather conditions and requires minimal maintenance, extending the lifespan of the building. Additionally, steel I-beams can be recycled at the end of their lifespan, reducing waste and conserving resources.

- Q:Can steel I-beams be used for architectural designs?

- Yes, steel I-beams can be used for architectural designs. Steel I-beams are known for their strength and durability, making them suitable for supporting heavy loads and creating large open spaces in architectural designs. They are commonly used in construction projects such as bridges, skyscrapers, and industrial buildings.

- Q:Is outside building protection single row bent with cantilever steel instead of channel steel?

- Construction of single door rack erection of cantilever I-beam steel can not be used instead of steel, because the provisions of article 6.10.2 JGJ130-2011 "construction of steel tubular scaffold safety technical specifications" cantilever beam application of biaxial symmetry,...... steel beams shall not be less than 160mm. Therefore, the channel shall not be used, the cross section is asymmetrical, and the cantilever bent, the cross section is more likely to be unstable.

- Q:How do steel I-beams contribute to the overall energy efficiency of a structure?

- Several factors contribute to the overall energy efficiency of a structure when using steel I-beams. Firstly, the durability and long lifespan of steel make it an ideal material for construction. This means that buildings constructed with steel I-beams require less maintenance and repairs over time, resulting in reduced energy consumption and costs associated with upkeep and renovations. In addition, steel I-beams have excellent load-bearing capabilities, allowing for larger spans and open floor plans. This means that fewer beams are needed to support the structure, resulting in reduced material usage and lower energy requirements during manufacturing and transportation. Moreover, steel is highly recyclable, and at the end of their lifespan, steel I-beams can be easily repurposed or recycled. Recycling steel requires significantly less energy compared to producing new steel, resulting in reduced energy consumption and greenhouse gas emissions. Furthermore, steel I-beams are often used in combination with other energy-efficient building components, such as insulated panels or double-glazed windows. This integration improves the overall thermal performance of the structure by reducing heat transfer, minimizing energy losses, and enhancing insulation. Lastly, steel I-beams can be designed to accommodate various energy-efficient systems, such as solar panels or geothermal heat pumps. These systems can be seamlessly integrated into the structure, further reducing energy consumption by providing renewable energy sources or utilizing the earth's natural heat. In conclusion, by incorporating steel I-beams into the design and construction of a building, energy consumption, costs, and environmental impact can be significantly reduced. The durability, load-bearing capabilities, recyclability, compatibility with energy-efficient components, and ability to accommodate sustainable technologies make steel I-beams an excellent choice for enhancing the energy efficiency of structures.

- Q:Can steel I-beams be used in power plants?

- Yes, steel I-beams can be used in power plants. They are commonly used to support heavy loads and provide structural stability in various applications, including power plant construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

I Beam Steel YBT24 for Mining Applications with Large Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords