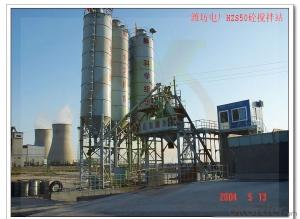

HZS50 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

Concrete mixing plant-HZS50

Theoretical productivity 50m3/h

Mixer model JS1000

Mixer nomination capacity 1000L

Mixing largest aggregate 80mm

Mixing motor power 2x18.5kw

Lifting motor power 15kw

Aggregate batcher PL1600

Aggregate bin capacity 3x3.7m3

Aggregate batching capacity 1600L

Aggregate types 3

Powder bin capacity 50/100t(Optional)

Screw conveyor 35t/h

Aggregate measuring precision ±2%

Powder measuring precision ±1%

Water measuring precision ±1%

Additive measuring precision ±1%

Discharging height 3.8m

Power 100kw(Without screw conveyor)

Weight 40t(Without screw conveyor and cement bin)

Dimension Depends on the configuration and equipment layout

- Q:What is the daily routine of the concrete mixing station?

- The work of the mixing station is simply the process of production - delivery - construction - curing. Each process consists of the raw materials - the mixing platform - the dispatcher - the on-site technical service. A mature mixing plant are two of the most important department: laboratory and operation department, laboratory to ensure the concrete product quality, operation department to ensure the construction process of concrete delivery smoothly. The other departments serve the two departments.

- Q:What is the concept of on-site concrete mixer station

- Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Action: concrete mixing plant is used to concentrate the mixing of concrete, also called concrete precast. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions. Basic introduction: concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities.

- Q:What constitutes the js750 concrete mixing station

- pecific configuration can be cut can be numerous js750 hosts are commonly used to climb a pipe loading, the concrete quality requirement is not high do not need automatic batching only buy a belt bucket host to climb to go, with a tractor modified small forklift about yao to climb add material in the bucket.

- Q:What raw materials and equipment do you need for your own admixture?

- The admixture of concrete mixing station using a lot of more phyletic, the effect is different also, early strength agent, retarder, water reducing agent, and release agent, antifreeze, etc., which is a kind of do not know you to call. The admixtures are usually made by professional manufacturers, and the ingredients are not the same.

- Q:The main components of a mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system.

- Q:Classification of concrete mixing stations

- There is the distinction between level 1, level 2, level 3. Because some projects, especially the project of the state, are required to provide the units of concrete, and the quality is low because of the low quality. There is a clear list of bids in general.

- Q:Which staff does the concrete mixing station need?

- Move the cement iron pipe, driver! technology, webmaster, laboratory (deputy) director of the general, production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians,

- Q:What are the supporting facilities for the concrete mixing stations?

- Mixing station can be divided into single and double machine stand, as the name implies, stand-alone station each station has a mixing console, the double machine station has two mixing console, each mixing console has a discharging mouth, so double machine mixing plant is a stand-alone station 2 times of production capacity.

- Q:What are the advantages of HZS series of concrete mixing stations

- HZS75 concrete batching plant investment amount, less occupied area is small, the use of equipment, maintenance easy, can be equipped with high performance of independent control room, make the equipment operation convenient and safe, and in the batching machine also can produce high quality under the condition of accurate measurement of concrete. This type of mixing station under our positive study also used the green environmental protection design, the construction of a possible pollution under control, rather than the old way of construction and transportation pollution, nature is winning.

- Q:What chemical materials are used in the concrete mixing station?

- Start with the glue: cement, coal ash, mineral powder, and various expansions! Sand: natural sand, mineral sand, fine sand; Stone: 5-10, 5-20 water reducer! And tap water

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HZS50 Concrete Batching Plant / ISO & CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords