Hydraulic Single Drum Road Roller S816C Road Building Machinery 18T

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: S816C Road Roller

Parameter:

Model | Unit | S816C |

Operating weight | kg | 16000 |

Weight on front drum | kg | 7700 |

Static linear pressure | N/cm | 362 |

Speed range | km/h |

|

Speed I |

| 2.54 |

Speed II |

| 4.97 |

Speed III |

| 10.51 |

Theoretical gradeability | % | 30 |

Min. external turning radius | mm | 6500 |

Steering angle | ° | ±33 |

Oscillating angle | ° | ±11 |

Vibration frequency | Hz | 28 |

Nominal amplitude (high/low) | mm | 1.9/0.95 |

Excitation force (high/low amplitude) | kN | 290/145 |

Engine model |

| SC8D156.2G2B1 |

Type | Water cooled, pressurized | Water cooled, pressurized |

Max. power | kW | 115@1800r/min |

Engine oil consumption | g/kW.h | 230 |

Hydraulic oil tank capacity | L | 170 |

Fuel tank capacity | L | 240 |

Advantages:

state-owned company

fortune 500 company

AAcustom

Why choose us?

1 Sincre

CNBM International is a state company, now is one of the largest state-owned group cooperation in China!

All the equipment such as tower cranes, produced by CNBM are compliant with the national level quality.

2 Professional

Our engineers will at your services 24hours to solve all your tower crane installation and other questions. Our goal is to provide the best professional services.

3 Quality

CNBM International’s tower crane have strict quality control, only the best quality products can pass the test.

4 Speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

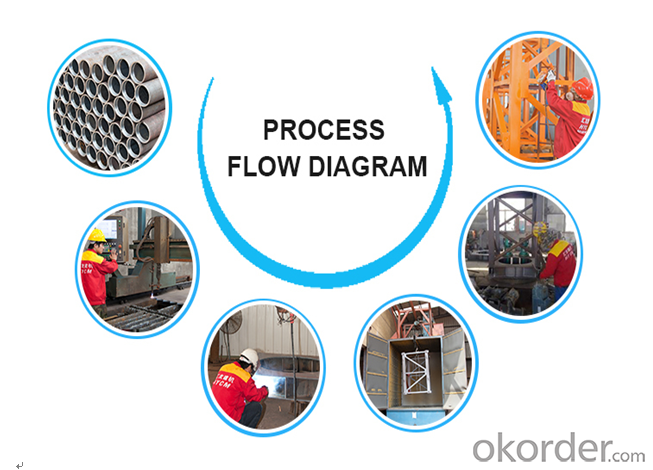

Pictures

- Q:What is the Jingyinshuangzi roller brainwashing and three tragedies to sing the song?

- The prisoner series, well, len Rin is the prisoner is patient, they through the paper plane communication, Rin's father found to go to len the plane tore, len played Rin's dad angry... Finally, len went into the gas chamber and Rin died.

- Q:Shaanxi impact roller manufacturers which scale is relatively large?

- Aviation equipment, Harvey machinery, Yutong heavy industries, are good, hope to adopt

- Q:1. what type of vehicle does the roller belong to?2. can the roller run on the road without work?3. what are the laws and regulations on road vehicles such as rollers?4. a case: a car on the road when the rear end hit a roller inside the car tail, causing casualties, ask how the roller will be responsible? What is the legal basis for the responsibility?

- I used to open digging at the site, I know the mechanical crawler excavator is not directly on the road. There should be no problem with the rollers. The vibration and the iron wheels are all straight to the road!

- Q:What is the influence distance of the road roller on the building?

- It's a professional question. I really don't know,

- Q:How does the municipal asphalt pavement budget do not have a wheeled roller?

- Municipal asphalt pavement construction quota, already contains a roller and paving machine cost, you can audit and said, don't fixed costs, change according to the market price of Jixietaiban, and don't forget the large machinery import charges.

- Q:How many tons are there in the maximum roller?

- There are more than 30 heavy duty roller rollers, such as XP302.Press machine road normally rolling efficiency and the compaction effect is proportional to its mass, so for higher grade, compaction material is complicated and the construction cycle is short of the road should be considered roller of large tonnage, construction equipment and large tonnage roller is the construction unit of the project bidding must be available, so in general should consider buying weight above 14T, the exciting force of more than 260kN wheel drive single drum vibratory roller. But it is not the exciting force of the bigger the better, because the exciting force will lead to segregation of surface layer, loose aggregate crushing and grading materials, not only reduce the compaction quality, but also can cause premature fatigue of drivers and machine parts damage, experience has shown that effective excitation maximum should not exceed 400kN.

- Q:Why is the roller driving force facing the paver when the asphalt is laid and rolled?

- The exact requirements should be paved and rolled according to the direction of the road.

- Q:OGFC why the use of less than 12 tons of steel tube roller

- Because it should be careful with vibration rolling and roller roller compaction, and pay attention to avoid excessive grinding. At the beginning of rolling, the opportunity of pressing the road is closely followed, and the paver should not be too spaced. After the paving, the initial degree of compaction is great. It has been proved by practice that the direct rolling process can be directly applied to the complex pressure process without serious deterioration, otherwise, it should be rolled according to the requirements of the SMA pavement.

- Q:What is the exciting force of XCMG 23t vibratory roller?

- The exciting force is 360/20KN.Force (exciting) is the periodic harmonic vibration produced by the unbalanced mass of the vibration as the vibration source of the vibration system. It is called the exciting force, and the unbalance mass is the vibration polarization.Vibratory roller is to use its own gravity and vibration compaction of various construction and road construction materials.

- Q:How much is the new machine for the 22 ton roller?

- 22 tons of vibroll new car price, to see the brand, configuration, take Xugong 22 tons of new machine for example, high, Saul pump, electronic files,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Single Drum Road Roller S816C Road Building Machinery 18T

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords