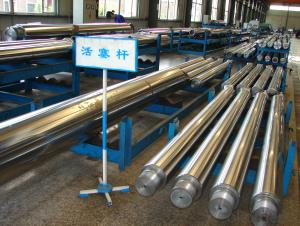

hydraulic ram for excavator heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q:The main difference between hydraulic circuit and pneumatic circuit

- I. pneumatic basic circuit is the basic component of pneumatic circuit, and complex pneumatic operation system is composed of one or more basic circuits. Compared with hydraulic, pneumatic circuit has its own characteristics:1, an air compressor can simultaneously supply gas to multiple circuits, while hydraulic pumps generally provide only one loop.2. The compressed air will be discharged into the atmosphere directly after the end of the cycle. No hydraulic drive will be necessary to recover the oil into the tank.3, air senior lubrication performance is poor, need additional oil supply device.Two, through the introduction of the previous articles, we generally understand the hydraulic circuit and the use of pneumatic circuit, as well as related presentations, and then we will explore how the cylinder should be chosen.Standard cylinder selection process is generally based on the needs of the job to determine the type of cylinder, installation forms, working pressure, cylinder and stroke, cylinder standard series and product samples for selection, gymnastics as;1, the cylinder output size of the load by 1.15~2 times to select, and accordingly determine the cylinder bore.2, according to the implementation of the agency's travel requirements to determine the cylinder piston stroke length, usually need to leave the margin of 5-20mm.3, according to the speed of the piston movement, select the appropriate inlet diameter, the greater the value, the faster the speed. In order to make the speed steady, a cylinder with a buffer device can be used.

- Q:What kind of material is the hydraulic cylinder of loader?

- There are two kinds of damage to the cylinder liner: the abrasion of the cylinder mirror and the corrosion on the outer wall of the cylinder liner. First, the cylinder mirror wear in the following situations: normal wear, abrasive wear, melting wear and corrosion, wear and so on. 1, normal wear, piston ring and cylinder mirror friction caused by, also known as friction and wear. The maximum wear position of the cylinder mirror surface is the position of the piston near the first ring at the top dead point, which often forms an obvious step. Because of this position, the maximum pressure of the cylinder piston ring on the mirror, the upper end of the cylinder with high temperature, abrasion resistance of metals decreased, at the same time, the piston at TDC speed is zero, the oil film is not easy to form, so the lower part of the cylinder wear mirror also larger. Abrasive wear is caused by heavy dust or carbon deposits in the air. Dust is sucked from the upper part, and the carbon deposits are formed in the upper part, so the upper part of the cylinder mirror is relatively worn. When the engine oil is thrown from bottom to top, the hard particles are affected by gravity, so the lower part of the cylinder is more worn. Abrasive wear is characterized by parallel, rectilinear strains of pulling from the cylinder mirror along the direction of the piston.

- Q:Solenoid valve, cylinder should use VG32 turbine oil, I use 46# hydraulic oil instead?

- No, VG32 turbine oil has the best effect, and several others will cause viscosity in use, which will affect the overall efficiency of pneumatic components

- Q:Can you tell me if the cylinder can be changed into an oil cylinder (low pressure)?

- Impossible, otherwise, the volume is not the same.

- Q:Is the cylinder usually faster than the hydraulic cylinder?

- When the compressed air flow is the same as that of the hydraulic source, the speed of the cylinder and the hydraulic cylinder are the sameIn actual use, the general air compressor low pressure air compressor driven by the same motor power output than hydraulic machine, so the result of the action of hydraulic cylinder cylinder than subconsciously think fast.

- Q:press the stroke 3CM, and then use the shearing machine as nitrogen cylinder return stroke, and then press down again 3CM.Consult you, 300 tons of hydraulic cylinder pressure, 28 MPa downward pressure stroke 3CM, and then use a shear plate as nitrogen cylinder return, and then press down again 3CM. 40 times per minute, OK? Is it feasible to do so?I would like to refer to the principle of shearing machine, to do a 3CM stroke 300 tons hydraulic press. Is that feasible? Since I need a very short stroke, I would like to use an ordinary larger cylinder instead of a fast cylinder. The return trip would also like to use nitrogen, which would make the hydraulic part the simplest, not knowing whether I was right or not

- The difference is that the pendulum shear is the return cylinder of the nitrogen return cylinder! Both pendulum shearing machine and gate shearing machine adopt single acting hydraulic cylinder! Jianhu Huabo hydraulic guillotine shears is accumulator return

- Q:Is the hydraulic cylinder at rated pressure the greater the stroke and the greater the pressure, is there a formula?

- Bore diameter: hydraulic cylinder jacket, unit mm;Hydraulic pressure: hydraulic system to provide the maximum hydraulic pressure, unit MPa * 10.Such as:If the bore 280mm, hydraulic pressure of 25 MPa, then the cylinder thrust3.14 * (28 / 2) x 2 (25 x 10) / 1000=153.86 (ton)

- Q:After running in, the upper cylinder head, the hydraulic jacking rod and the rocker arm are also arranged in the original position, and the cylinder head is not provided with a valve body without gaps

- I. valve clearance: when the valve is completely closed, the gap between the end of the valve stem and the component of the valve train is called the valve clearance. Two, the valve clearance is necessary: when the engine works, the valve will be due to temperature expansion, if the valve and its transmission parts, in the cold when no gap or clearance is too small, in the hot state, and the transmission of the thermal expansion valve will cause the valve is not tightly closed, causing the engine leakage in the power stroke in compression and the power down, don't even start easily when serious. In order to eliminate this phenomenon, the valve clearance is usually used in the cold assembly of the engine to compensate for the expansion after the valve is heated. Some engines use hydraulic tappet, the length of tappet can change automatically, and the thermal expansion of the valve is compensated at any time, so there is no need to reserve the valve clearance. Three, the valve clearance is too large and too small damage, the size of the valve clearance by the engine manufacturer, according to the test to determine. Generally in cold state, the clearance of intake valve is 0.25mm~0.35mm, and the clearance of exhaust valve is 0.30mm~0.35mm. 1, too small: if the valve clearance is too small, the engine in hot state may be due to valve closed lax and leak, leading to power down, or even valve burned.

- Q:What is the four link mechanism of hydraulic support?

- Four link mechanism is an important part of hydraulic support, including: connecting rod, rear connecting rod, shield beam and base.1. The connecting rod group consists of the connecting rod body, the connecting rod big head cover, the connecting rod small head bushing, the connecting rod big head bearing bush and the connecting rod bolt (or screw). The connecting rod group bears the force acting on the piston pin and its swing and the reciprocating inertia force of the piston group, and the magnitude and direction of these forces are periodically changed. Therefore, the connecting rod is subjected to alternating load such as compression and tension.

- Q:What is the working pressure of the hydraulic cylinder with a diameter of 80?

- Hydraulic cylinder can be divided into medium pressure, low pressure, medium high pressure and high pressure hydraulic cylinder. For the machine tool machinery, generally used in low pressure hydraulic cylinder, the rated pressure is 2.5MPa~6.3MPa; for the requirements of small size and light weight, large output of construction vehicles and aircraft with hydraulic cylinder used in high pressure hydraulic cylinder, the rated pressure is 10MPa~16MPa; the mechanical hydraulic machine, crane class, most of the high pressure hydraulic cylinder, rated the pressure is 25MPa~35MPa.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

hydraulic ram for excavator heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords