Hydraulic plate rolling machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Place of Origin: | Jiangsu China (Mainland) | Brand Name: | HAIWEI |

| Model Number: | W11s series | Machine Type: | Roller-Bending Machine | Raw Material: | Sheet / Plate Rolling |

| Material / Metal Processed: | Carbon Steel | Power: | Hydraulic | Automation: | Automatic |

| Extra Services: | End Forming | Certification: | ISO 9001:2000,ISO,SGS,BV | After-sales Service Provided: | Overseas service center available |

| Colour: | green or as client's request | Exported to Countries: | UAE, RUSSIA, INDIA AND SO ON | Control: | PLC/CNC |

| products name: | hydraulic plate rolling machine |

Packaging & Delivery

| Packaging Detail: | STEEL PALLET. |

| Delivery Detail: | 100days |

Specifications

1:CNC/NC control

2:Pre-bending functions

3:Hydraulic system

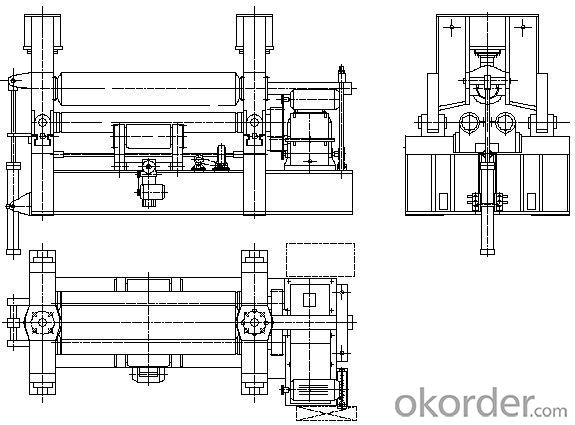

hydraulic plate rolling machine

1,Japan hydraulic system,

2,NC control with touch screen,

3,pre-bending of high precision,rich bending shapes such as O,U

3 Roller Hydraulic Plate Rolling Machine

More than 20years rolling machinery making experience

The biggest plate rolling machine manufacture in China

Precision of the superior products

Unique crooked craft , the high-accuracy tip is curved in advance, the crooked angle after not having in succession, the crooked course is digital control.

Man-machine dialogue controls the high-efficient intelligence of interfaces to operate

Peculiar crooked craft software, the interactive window, the automatic compensation of the crooked course, operate singly, high-efficient and safe and convenient!

Abundant crooked form

Have rolls of form to make O type, U type, many sections of R ,etc. different forms.

Choice of many models According to the use or users' enquiry, count and show the model economily, TC numerical control model chooses.

3.The Main Structure:

This equipment should be composed of main structure, hydraulic system , electricity control system and cone device.

3-1. The main structure

The main structure is composed of upper roller , down rollers and level motion device support rolls device , tuning device , balance device, lubricate device , left and right work frame and bottom plate.

1) The upper roller

upper rolls device composed of main cylinder, upper bearing pedestal, upper rolls, double self-aligning bearing .two cylinders provide the pressure for upper roll bending , main cylinder working pressure is 20 Mpa ,max pressure of upper roll multiply 0.8 times to compensate for pre-bending. Upper roll two ends fit with double self-aligning bearing to reduce the friction and motor power.

The material of upper roll is 42CrMo , heat treatment is HB220-280. HRC 45-55

- Q:What gear is machined out of the gear?

- Modern is the use of Fan Chengfa, straight or helical gears in the hobbing machine with a gear hob or machining on the gear machine with a tooth cutter, in order to improve gear accuracy, as well as honing and gear grinding machine.

- Q:Main classification of hydraulic machinery?

- (4) According to the importance of equipment in the production system or application classification, hydraulic equipment can be divided into key equipment, key equipment and general equipment.

- Q:What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q:What is the principle of the cutting order in machining?

- ② first after the first hole after the first processing plane, after processing holes.

- Q:Information on building materials decoration.

- What are the building materials industry? Wallpapers Flooring Pallet Handling Machinery Fireproof Materials Waterproof and Moistureproof Materials Heat Absorbing Sound Absorbing Materials Pipe Fittings Concrete and Products Activities Furniture Manufacturing Machinery Building Materials Processing Building Glass Construction Related Equipment Construction Project Cooperation Adhesive Metal Building

- Q:Mechanical processing technology to mechanical product design, specifically to prepare what?

- Electrical aspects of more understanding to understand, engage in design to consider more problems, and often a project is not a person can get, need is a technical team.

- Q:Classification and components of hydraulic press

- according to the size of the equipment according to the size of equipment, hydraulic equipment can be divided into large equipment, medium-sized equipment, small equipment.

- Q:What are the aspects of the mechanical processing quality

- Parts of the processing accuracy includes three aspects of the content; dimensional accuracy, shape accuracy and position accuracy

- Q:Information on building materials decoration.

- Products Special Building Materials Ceiling Coatings Culture Stone Bamboo Processing Machinery Brick, Watt and Block Decorative Building Materials Agent

- Q:What are the oyster processing companies?

- other electronic processing metal processing including | casting pressure processing welding and bonding heat treatment cutting sheet metal processing Electroplating processing CNC and CNC machining line cutting processing other metal processing glass processing ceramic processing rubber processing including rubber rolling processing rubber molding processing rubber post processing processing other rubber processing plastic processing including injection molding extrusion processing blow molding processing plastic processing plastic processing casting Plastic Processing Plastic Surface Treatment Other Plastic Processing Textile Processing Including Spinning Processing Weaving Processing Dyeing & Finishing Quilting Processing Embroidery Processing Hand Knitting Processing Other Textile Processing leather processing entertainment leisure products processing health care products processing business printing processing including brochures

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic plate rolling machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords