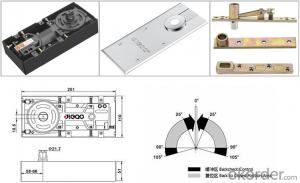

Hydraulic Door Hinge/ Door Closer/Floor Spring for Glass Door/Floor Hinge for Glass Door FS-838

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INTRODUCTION

Floor Spring is used for glass door, and they can be used together with door clamp. Floor Spring can be opened with double sizes, and on this point, it is different from that of door closer, which can just be opened by one size. The key of technique lies on the loading seat under the main bearing, which decides the level of loading on the floor spring. Usually it can be opened from 300thousand or 1million times

FEATURES

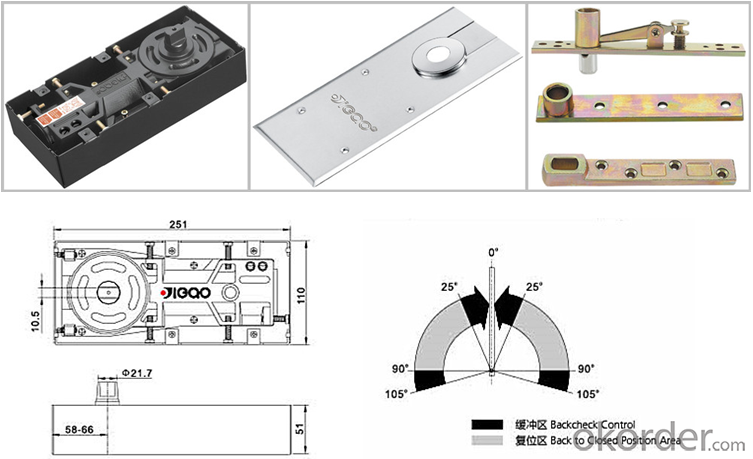

u Applicable for glass doors, wooden doors and the glass doors of metal frame and wooden frame.

u Floor spring comply to EN 1154 and GB standard , and fire-rated EN1634 standard.

u Maximum 500000 cycles tested without damage or maximum 7 years guarantee.

u Double ways opening with smoothly movement, hold-open at 90°.

u Closing speed and latching speed adjustable, latching point accurately at 0°

u Stainless steel cover plate, satin or mirror surface available.

u High quality casting iron floor spring body with 2 layers anti-rust coating.

u All spindle types available for different countries.

u Germany hydraulic machine oil and sealed rings, keep perfect working in cold temperature.

SPECIFICATION

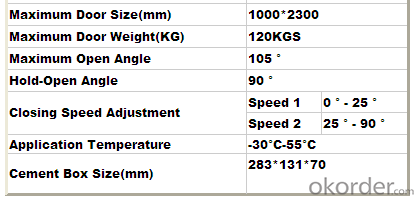

INSTALLATION STEPS

1. Draw lines and make floor spring pivot center and door-nip pivot coincide with each other.

2. Drill holes on the floor according to the instructions. The sizes of the holes must tightly match the floor spring.

3. Place the floor spring into the holes and position it.

4. Raise the door leaf installed with door-nip, and insert the floor spring pivot into the hole of the door leaf.

5. Adjust the screws at three directions. Make them vertical and the upper and lower pivot center coincide with each other.

6. Adjust the speed of door closing.

7. Put the decoration cover on the floor spring.

Package

Workshop

Testing Room

- Q:Want to practice how to use pectoral muscle spring expander

- If your strength is not enough, a chest start even more difficult, not easy to do it.It is recommended that you should not rely solely on the chest muscle training, according to their ability, to start from the first push ups. Practice to a certain extent to practice chest.If possible, the best way is to do chest push arms parallel flexion, but more difficult.The best chest group 20, a group is appropriate.

- Q:What kind of material does spring have?

- Carbon spring steel: the material: 65#, 70#, 65Mn, 82B, 72A, 72B steel, is characterized by low plasticity, strong elasticity, anti stress ability. Application: mainly used for Simmons bed, car cushion, and all kinds of machinery, electric tools, stationery, sports equipment, torsion spring, spring, electrical equipment and other industries. Specifications: line diameter 0.20mm- GB4357-89 6.50mm. standard: carbon spring steel wire, national standard, main use: used to make cold formed in the cold state without hardening spring

- Q:Can springs be used for support?

- One point, the spring you choose to bear the force is higher than the gear weight pressure, if higher than, then the spring to withstand 0. Unless the heat changes, the spring steel is denatured. Long periods of rust change can also make a difference. Deal with the above two points. 0 pressure spring does not exist short pressure

- Q:What kind of spring has the best performance?

- Spring verticality, verticality is bad, will directly affect the strength and life.

- Q:Spring dynamometer and spring balance what is the difference

- Spring dynamometer and spring balance what is the differenceThis is a question of grade seven (junior one).You didn't answer all right. I found it on the Internet now:The size of the measurement tool called spring dynamometer, dynamometer is a commonly used dynamometer (including spring scale), the experiment is in common is the spring balance.Also, the spring scale is used to measure the force, not to measure the quality.

- Q:How to process Spring Steel

- The available oxygen converter furnace and open hearth furnace or general production of spring steel; high quality spring steel or better quality with special properties, furnace or vacuum refining furnace. The content of carbon, manganese, silicon and other major elements in spring steel is narrow, and the chemical composition must be strictly controlled during smelting. When the silicon content is high, it is easy to form bubbles and other defects. After the ingot is rolled and rolled, the cooling is not easy. Therefore, the raw materials used for smelting must be dry, as much as possible to remove gas and inclusions, and to avoid overheating of the steel.

- Q:What are the main functions of spring?

- The storage and release of energy, for example, the clock spring bolt spring

- Q:Buffer spring buffer for automobile

- Rubber buffer also known as buffer, buffer, buffer block, rubber shock absorber, shock absorber rubber and so on, the most correct name is "automobile spring cushion", is the name of Car Spring Buffer Retainer English, 1 luxury cars with a buffer principle significantly improve the damping performance of vehicles.

- Q:Cold rolled coil spring spring and difference "

- Coil is to burn the red, generally large diameter to coil

- Q:What's the spring material to?

- 1, with alloy spring steel, respectively, there are several kinds of steel: 55Si2Mn or 50CrVA and 30W4Cr2VA, these alloy spring steel;2, manufacturing process:Coil the machine first into the spring and then proceed with the proper heat treatment process to get the spring you need.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Door Hinge/ Door Closer/Floor Spring for Glass Door/Floor Hinge for Glass Door FS-838

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords