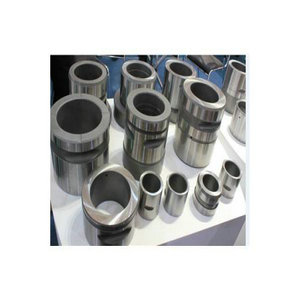

Hydraulic Cylinder bushing of chinese manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Hydraulic Cylinder bushing (SF-1D)

1.steel backing,sintered porous bronze,PTFE layer

2.oilless,self-lubricating

3.low wear

Hydraulic Cylinder bushing (SF-1D) introduction:

1. Hydraulic special bearings is a new type op material, which in basis of SF-1P and designed in principles of oil and shock absorber. it become more wear-resisting under breaking off the lubricating oil .these products also particularly suitable for the frequent reciprocating motion besides having the advantages of SF-1P.

2. Its properties is similar to that of the foreign product designated as DP4,Currently the product gradually replace SF-1P,applying to auto shock absorber, hydraulic cylinders and other various fields.

Load capacity 120N/mm2

Max Speed 2m/s

Friction Coefficient 0.04~0.20

PV Limit (dry) 3.6N/mm2 m/s

PV Limti (oil) 50N/mm2 m/s

Temperature Limit -195oC ~+270oC

Why use Cast brass Bearing?

long service life and maintenance-free

High load capacity

High wear resistence

low coefficients of friction

Good heat conductivity

High corrosion resistence

- Q:What are plain bearings, roller bearings, roller bearings, needle roller bearings?

- Needle bearing roller bearings are cylindrical roller, relative to its diameter, the roller is thin and long. This roller is called needle roller. In spite of the small cross section, the bearing still has a high load capacity, so it is especially suitable for radial space limited occasions.

- Q:Which foreign brands are good for self lubricating sliding bearings?

- their advantage is rolling oil lubrication;Self lubrication words: THORDON in Canada, DRIE in the United States, GGB in Japan, OILERS in japan;These brands;Specific words, each brand has a concentrated market and areas, but also depends on your specific application!

- Q:Deep groove ball bearings are better than plain bearings Which one is better?

- The precision of deep groove ball bearings is better than that of plain bearings in Rongchang, and the accuracy of sliding bearings is not as high as that of deep groove ball bearings.

- Q:What kinds of checks should be carried out for the design of non full liquid friction sliding bearings? Explain why, what does the PV value mean?

- therefore recommended design make use of safe PV low value, to ensure that the bearing will have longer service life;

- Q:In general, what kind of sliding bearing material is used in the case of large load?

- The material selection of sliding bearing is related to load, speed, lubrication conditions, and the self-lubricating materials chosen in different working conditions are different.

- Q:What are the four types of commonly used sliding bearing alloys?

- Babbitt, copper alloy, cast iron, rubber, nylon are also useful in wood.

- Q:Why is the starting resistance of plain bearings high?

- Their production mechanism and effect are differentAn object (such as wheel) on another object surface for rolling without sliding when (pure rolling), due to the two objects in the contact part of the compression deformation of block rolling, called "rolling friction." is generally used to measure the rolling friction resistance moment, the size and the force of the nature, objects the shape of the surface and rolling the weight of the object.

- Q:What are the properties of plain bearing alloys?

- The sliding bearing alloy should have the ideal organization of both hard and soft:(1) soft matrix and uniformly distributed hard point.(2) a soft particle is arranged on the ideal tissue of the hard base sliding bearing alloy. When the bearing is working, the soft tissue is firstly worn down and sunken, and the lubricant can be stored to form a continuous distribution of oil film, while the hard component plays the role of supporting the journal. Thus, the actual contact area of the bearing and the shaft neck is greatly reduced, so that the friction of the bearing is reduced.(3) the sliding bearing alloy has sufficient compressive strength and anti fatigue performance; good performance for reducing friction (friction coefficient is smaller); reserve good lubricating function; good adaptability; good thermal conductivity and corrosion resistance; good process performance, which is easy to manufacture, low price.

- Q:How is the normal operating temperature of the sliding bearing bush determined?

- Shaft vibration and shaft temperature are the two main parameters that reflect the bearing state, so it should be analyzed from the two aspects.1.1 axis vibration if the unit has the following problem: A. magnetic force line misalignment, appears to exceed the standard deviation of gap; B. motor interturn short circuit, load imbalance; C. turbine rotor unbalance or vibration; D. installation is found, the ultra poor bearing ultra poor gap, the connection is not good. All these problems will lead to higher vibration value of bearings, but the difference is that the severity is not the same.The axial vibration is affected more directly and the data is more intuitive and accurate, so it can be monitored, analyzed and judged in real time. Generally, we adopt the method of setting upper limit axial vibration value and standard axial vibration value, and within the two value range, all belong to the normal operation category. Run 1.2 axle temperature units in addition to the above problems, but also has the following problems: A. may appear tungsten bearing hanging layer defects; B. lubricating oil and lubricating the surface problems; problems of C. oil and cooling system.

- Q:How to distinguish sliding bearings and rolling bearings?

- Rolling bearings are relatively moving parts with rolling bodies for rolling bearings. Rolling bearings are generally made up of outer rings, inner rings, rollers, and cagesPlain bearings are bearings that work under sliding friction. In liquid lubrication, the sliding surfaces are separated by lubricant without direct contact

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hydraulic Cylinder bushing of chinese manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords