HRB400 High Tensile Rebars for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

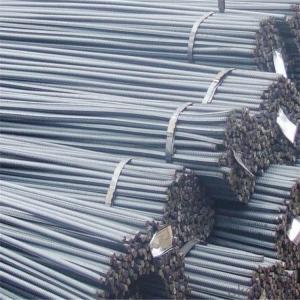

HRB400 High Tensile Rebars for Building Material

Description of HRB400 High Tensile Rebars for Building Material

1, Diameter: 5.5mm-10mm HRB400 High Tensile Rebars for Building Material

10m- 40mm HRB400 High Tensile Rebars for Building Material

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of HRB400 High Tensile Rebars for Building Material

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of HRB400 High Tensile Rebars for Building Material

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:How does special steel contribute to the waste management industry?

- Special steel contributes to the waste management industry in various ways. Its exceptional strength, durability, and resistance to corrosion make it ideal for manufacturing equipment used in waste management processes. Special steel is extensively used in the construction of waste sorting systems, recycling machinery, and waste containers, ensuring their longevity and reliability. Additionally, special steel can be recycled itself, reducing the environmental impact of waste management operations and promoting sustainability in the industry.

- Q:What are the challenges in heat treatment of special steel?

- Some challenges in the heat treatment of special steel include achieving the desired hardness and strength without compromising other properties, such as toughness and corrosion resistance. Special steels often have complex compositions, which can make it difficult to accurately control the heat treatment process. Additionally, heat treatment of special steel can be time-consuming and costly due to the need for precise temperature and time control, as well as the potential for distortion or cracking during the heat treatment process.

- Q:Can special steel be used in the furniture manufacturing industry?

- Yes, special steel can be used in the furniture manufacturing industry. Special steel offers various advantages such as strength, durability, and corrosion resistance, making it suitable for producing sturdy and long-lasting furniture pieces. Additionally, special steel can be molded and shaped into various designs, providing flexibility and creativity in furniture manufacturing.

- Q:How does special steel perform in cryogenic ductility?

- Special steel performs well in cryogenic ductility. It is able to maintain its flexibility and ability to deform under low temperatures without experiencing brittleness or failure. This makes it suitable for applications in cryogenic environments where materials need to withstand extreme cold temperatures while maintaining their mechanical properties.

- Q:What are the properties of electrical steel?

- Electrical steel, also known as silicon steel, possesses several important properties that make it suitable for various electrical applications. It has a high magnetic permeability, which means it can efficiently conduct magnetic flux, making it ideal for use in transformers, motors, and generators. Additionally, electrical steel exhibits low core losses, reducing energy dissipation during operation. Its high electrical resistivity minimizes eddy currents, further improving efficiency. Furthermore, electrical steel has a laminated structure, reducing hysteresis losses and preventing magnetic domains from aligning, which helps in maintaining a stable magnetic field. Overall, electrical steel's properties make it a crucial material for efficient and reliable electrical devices.

- Q:Can special steel be used for making renewable energy equipment?

- Yes, special steel can be used for making renewable energy equipment. Special steel alloys are often used in the manufacturing of components such as wind turbine towers, solar panel frames, and hydroelectric power plant structures. These alloys possess high strength, durability, corrosion resistance, and other properties necessary for withstanding the harsh environmental conditions and demands of renewable energy systems.

- Q:What are the different types of maraging steel?

- There are various types of maraging steel, including Maraging 200, Maraging 250, and Maraging 300.

- Q:What are the main applications of special steel in the mining exploration?

- Special steel has various crucial applications in mining exploration. One main application is in the construction of drilling equipment, such as drill bits and drill rods, which require high strength and durability to withstand the challenging conditions of drilling in hard rock formations. Another important use of special steel in mining exploration is in the manufacturing of conveyor belts and other material handling systems, which need to be resistant to abrasion and corrosion. Additionally, special steel is employed for the fabrication of mining machinery components like gears, shafts, and valves, ensuring reliable performance and longevity under extreme operating conditions.

- Q:Can special steel be used in the beverage manufacturing industry?

- Yes, special steel can be used in the beverage manufacturing industry. Special steel, such as stainless steel, is commonly used in the beverage industry due to its corrosion resistance, hygiene properties, and durability. It is often utilized for the production of tanks, containers, piping, and other equipment involved in the processing, storage, and transportation of beverages.

- Q:How is corrosion-resistant alloy steel used in the production of chemical processing equipment?

- Corrosion-resistant alloy steel is used in the production of chemical processing equipment due to its ability to withstand the harsh chemical environments and resist corrosion. It is commonly used to manufacture pipes, tanks, valves, and other components that come into contact with corrosive substances. This type of steel helps ensure the longevity and reliability of the equipment, preventing leaks, contamination, and costly repairs or replacements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HRB400 High Tensile Rebars for Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords