Hrb400 Deformed Steel Bar Supplier from Tianjin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Hrb400 Deformed Steel Bar Supplier from Tianjin

Description of Hrb400 Deformed Steel Bar:

1, Diameter: 5.5mm-10mm rounds Hrb400 deformed steel bar

10m- 40mm Hrb400 deformed steel bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

Chemical Composition of Hrb400 Deformed Steel Bar:

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

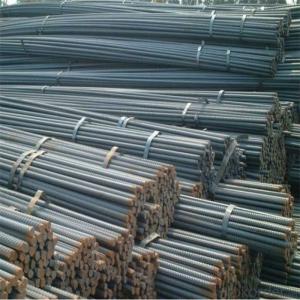

Product Show of Hrb400 Deformed Steel Bar:

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

- Q:What are the main factors affecting the formability of special steel?

- Several factors influence the formability of special steel, similar to other types of steel. These factors encompass the composition, microstructure, mechanical properties, temperature, and strain rate of the steel. The composition of special steel plays a vital role in determining its formability. The presence of alloying elements, such as chromium, nickel, molybdenum, and vanadium, can significantly impact the steel's ability to be shaped. These elements have the power to modify the steel's strength, ductility, and resistance to deformation. Another crucial factor influencing the formability of special steel is its microstructure. Fine-grained steels generally exhibit superior formability compared to coarse-grained steels. Additionally, the existence of non-metallic inclusions, like sulfides and oxides, can act as stress concentrators and promote crack formation, thereby influencing formability. The mechanical properties of special steel, including yield strength, tensile strength, and elongation, directly affect its formability. Steels with higher yield strength typically pose greater difficulty in shaping as they require more force for deformation. However, steels with high elongation can undergo more significant plastic deformation before failure, making them more formable. Temperature is also a critical factor impacting the formability of special steel. Elevated temperatures enhance the steel's ductility and make it easier to shape. This is due to the reduction in yield strength and increased movement of dislocations within the crystal structure. However, excessively high temperatures can lead to grain growth, negatively impacting formability. The strain rate, which refers to the rate of deformation applied to the steel, also influences formability. Higher strain rates can result in strain hardening, making the steel stronger but less formable. Conversely, lower strain rates allow for greater plastic deformation and improved formability. In conclusion, achieving the desired formability and shaping capabilities of special steel in various applications necessitates an understanding and optimization of its composition, microstructure, mechanical properties, temperature, and strain rate.

- Q:How does special steel contribute to the transportation equipment industry?

- The transportation equipment industry relies heavily on special steel for several reasons. To begin with, special steel alloys are utilized in the manufacturing of various vehicle components, including engine parts, suspension systems, and transmission components. These alloys possess exceptional strength, durability, and resistance to corrosion, ensuring that vehicles can withstand harsh operating conditions and have a longer lifespan. Furthermore, special steel is crucial in the production of railway tracks and infrastructure, which greatly contributes to the efficiency and safety of transportation systems. The high-quality steel used in railway tracks ensures stability, reduces maintenance requirements, and improves overall railway performance. Moreover, special steel is employed in the manufacturing of aircraft components, where precision, reliability, and lightness are of utmost importance. Steel alloys with outstanding mechanical properties are utilized in critical parts like landing gear, engine components, and structural elements, guaranteeing the safety and efficiency of air transport. Additionally, special steel plays a vital role in shipbuilding and the production of marine vessels. The use of corrosion-resistant steel alloys in shipbuilding helps to prevent rusting, extending the lifespan of vessels and reducing maintenance costs. Moreover, certain steel alloys with a high strength-to-weight ratio allow for the construction of lighter ships, resulting in increased fuel efficiency and reduced emissions. In summary, special steel's exceptional properties and characteristics make it an essential material in the transportation equipment industry. It enhances the performance, safety, and durability of vehicles, railways, aircraft, and ships, ultimately improving the efficiency and reliability of transportation systems.

- Q:What are the different types of welding techniques used for special steel?

- Special steel can be welded using various techniques depending on its specific requirements and properties. Some commonly used techniques for welding special steel include: 1. Stick welding, also known as Shielded Metal Arc Welding (SMAW), involves using a consumable electrode coated in flux to create an electric arc between the electrode and the base metal. This technique is ideal for thicker sections of special steel due to its ability to generate high heat and deep penetration. 2. Gas Metal Arc Welding (GMAW), also known as MIG welding, utilizes a continuously fed wire electrode and a shielding gas to protect the weld from atmospheric contamination. Its versatility and ability to produce high-quality welds with good control make it widely used for special steel. 3. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, employs a non-consumable tungsten electrode and a shielding gas to create an electric arc. This technique is often preferred for special steel alloys that require precise control over the welding process and where weld quality and appearance are crucial. 4. Flux-Cored Arc Welding (FCAW), similar to GMAW, employs a continuously fed tubular electrode filled with flux. This technique is commonly used for special steel applications that necessitate high deposition rates and deep penetration, such as heavy fabrication or structural welding. 5. Submerged Arc Welding (SAW) involves creating an arc between a continuously fed bare electrode and the workpiece, while a layer of granular flux covers the arc. This technique is typically used for heavy-duty applications and thick materials, providing excellent weld quality and high deposition rates. 6. Laser Beam Welding (LBW) utilizes a highly focused laser beam to melt and join special steel parts. It offers precise control, high welding speeds, and minimal distortion, making it suitable for specialized applications that require high precision and minimal heat-affected zones. It is crucial to consider factors such as material composition, thickness, joint configuration, and desired weld properties when selecting the appropriate welding technique for special steel. Expertise and knowledge are essential to determine the best technique for a specific application, ensuring optimal results in terms of weld quality, strength, and durability.

- Q:How does special steel contribute to the defense industry?

- Special steel contributes to the defense industry in various ways. Its exceptional strength, durability, and resistance to corrosion make it an ideal material for manufacturing military equipment, such as tanks, submarines, and aircraft carriers. Special steel is also used in the production of firearms, missiles, and armored vehicles, providing enhanced protection and performance capabilities. Additionally, its heat resistance and ability to withstand extreme temperatures make it suitable for crafting jet engines and other critical components used in military aircraft. Overall, special steel plays a crucial role in ensuring the reliability, safety, and effectiveness of defense equipment.

- Q:How does special steel contribute to the performance of cutting tools?

- Special steel contributes to the performance of cutting tools in several ways. Firstly, it offers exceptional hardness and strength, enabling the cutting tool to withstand the high forces and pressures encountered during cutting. This durability ensures that the tool remains sharp for longer periods, reducing the need for frequent replacements. Additionally, special steel also possesses excellent heat resistance, preventing the tool from overheating and maintaining its cutting ability. Moreover, special steel can have specific alloying elements that enhance wear resistance, corrosion resistance, and toughness, further improving the performance and lifespan of cutting tools. Overall, the use of special steel in cutting tools enhances their efficiency, reliability, and longevity, resulting in improved cutting precision and reduced downtime.

- Q:What are the different casting techniques used for special steel?

- Some of the different casting techniques used for special steel include investment casting, sand casting, continuous casting, and centrifugal casting. Each technique has its own advantages and is chosen based on factors such as the complexity of the steel part, the desired quality, and cost considerations.

- Q:How does special steel perform in terms of corrosion resistance in acidic environments?

- Special steel, such as stainless steel, exhibits excellent corrosion resistance in acidic environments due to its high chromium content. The chromium forms a protective oxide layer on the surface of the steel, preventing the corrosive attack of acids. This makes special steel a reliable choice for applications where exposure to acidic environments is a concern.

- Q:How does special steel contribute to reducing product failures in high-stress applications?

- Special steel contributes to reducing product failures in high-stress applications by offering enhanced strength, durability, and resistance to corrosion and wear. The unique properties of special steel allow it to withstand extreme conditions, such as high temperatures and pressures, without deformation or failure. This ensures that the products made using special steel perform reliably and have a longer service life, minimizing the risk of failures and resulting in improved safety and cost-effectiveness in high-stress applications.

- Q:How does special steel perform in high-temperature oxidation resistance?

- Special steel is specifically engineered to possess exceptional resistance to oxidation at high temperatures. This kind of steel incorporates alloying components like chromium, aluminum, and silicon, which generate a protective layer of oxide on the surface when subjected to extreme heat. This oxide layer acts as a barrier, preventing further oxidation and corrosion of the steel. The capacity of special steel to withstand high-temperature oxidation is of utmost importance in scenarios where the material is exposed to intense heat and oxidation, for instance, in gas turbines, heat exchangers, and furnaces. The protective oxide layer aids in preserving the strength and integrity of the steel, even under rigorous conditions. Moreover, special steel also showcases remarkable resistance to creep at high temperatures. Creep refers to the gradual distortion of a material under a consistent load and elevated temperatures. The distinctive composition of special steel grants it the ability to resist creep deformation, thereby enhancing its overall performance and dependability in environments with high temperatures. In conclusion, special steel exhibits exceptional performance in terms of resistance to high-temperature oxidation due to its alloying elements and the formation of a protective oxide layer. Its capability to resist oxidation and maintain its structural integrity at elevated temperatures makes it the preferred choice for numerous industrial applications.

- Q:What are the applications of special steel in the agriculture sector?

- Special steel has various applications in the agriculture sector. It is often used in the manufacturing of agricultural machinery and equipment such as tractors, plows, harvesters, and irrigation systems. The high strength and durability of special steel make it ideal for withstanding the demanding conditions and heavy loads typically encountered in agricultural operations. Additionally, certain types of special steel, such as stainless steel, are corrosion-resistant, which is crucial for equipment exposed to moisture and chemicals in the farming environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hrb400 Deformed Steel Bar Supplier from Tianjin

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords